Use of polyurethane PU core material , is hot zinc color surface layer (two layers) and high-strength adhesive, high-speed continuous automatic machine heat, pressure composite, after trimming, slotti...

Lin Sen Purification was founded in 2003. After 10 years of unremitting effort, Lin Sen has become an explorer and pioneer in purification industry.

Contact Supplier

Using flame retardant EPS as core material, for the surface layer of hot zinc color (two) and high-strength adhesive, high-speed continuous automatic machine heat, pressure composite, after trimming, ...

Lin Sen Purification was founded in 2003. After 10 years of unremitting effort, Lin Sen has become an explorer and pioneer in purification industry.

Contact Supplier

Using high-density rock wool as core material, galvanized or color coated as the surface layer (two layers) and high-strength adhesive, high-speed continuous automatic machine heat, pressure composite...

Lin Sen Purification was founded in 2003. After 10 years of unremitting effort, Lin Sen has become an explorer and pioneer in purification industry.

Contact Supplier

Paper honeycomb color steel laminboards colored coating for the panel, the paper honeycomb is core material, with a heat-curing adhesive in a continuous molding machine heated and pressurized lightwei...

Lin Sen Purification was founded in 2003. After 10 years of unremitting effort, Lin Sen has become an explorer and pioneer in purification industry.

Contact Supplier

Mechanism hollow glass magnesium color steel plate double-sided adopts coating / fluorocarbon / galvanized / static / steel (thickness 0.18mm-1.2mm). Core material for the inorganic magnesium plate gl...

Lin Sen Purification was founded in 2003. After 10 years of unremitting effort, Lin Sen has become an explorer and pioneer in purification industry.

Contact Supplier

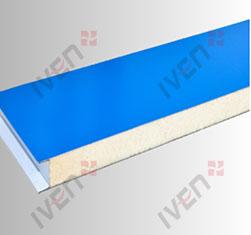

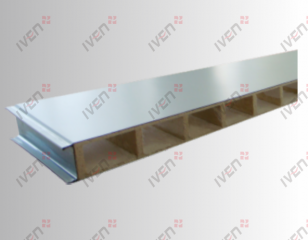

Use of polyurethane PU core material , is hot zinc color surface layer (two layers) and high-strength adhesive, high-speed continuous automatic machine heat, pressure composite, after trimming, slotti...

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier

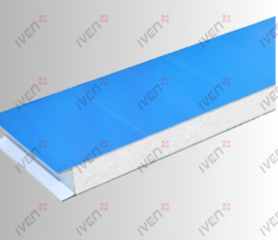

Using flame retardant EPS as core material, for the surface layer of hot zinc color (two) and high-strength adhesive, high-speed continuous automatic machine heat, pressure composite, after trimming, ...

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier

Using high-density rock wool as core material, galvanized or color coated as the surface layer (two layers) and high-strength adhesive, high-speed continuous automatic machine heat, pressure composite...

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier

Paper honeycomb color steel laminboards colored coating for the panel, the paper honeycomb is core material, with a heat-curing adhesive in a continuous molding machine heated and pressurized lightwei...

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier

Mechanism hollow glass magnesium color steel plate double-sided adopts coating / fluorocarbon / galvanized / static / steel (thickness 0.18mm-1.2mm). Core material for the inorganic magnesium plate gl...

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier

1.2.1 Feeding width range of the material:40-200mm 1.2.3 Strip steel texture:Q235 Cold-strip steel 1.2.4 Working speed: 15-20m/min 1.2.6 Tolerance of the straightnes...

Zhengchuang Machinery is a manufacturer of high-end roll forming machine in Asia. Wuxi Zhengchuang Cold Bending Technology Co., Ltd was establish in 1995, with more than 20 years history in cold bending industrial area. Our company is located in Wuxi city, Jiangsu Province, floor area is about 15,000M2. We are professional manufacturing all kinds of cold bending machines, with the 23 years development, we use modern management, professional scientific research, advanced manufacturing technique and impeccable after-sales system, we obtain national high-tech enterprise title, until now our company has more than 80 employees. What we offer? Zhengchuang is mainly produce color steel tile roll forming machine, glazed tile roll forming machine, C/Z purline roll forming machine, quick change roll forming machine, deck floor roll forming machine, guardrail roll forming machine, downpipe roll forming machine, automotive frame roll forming machine, steel silo roll forming machine etc. We can make more than 20 series 100 kinds machines. The end product is widely used in grain storage, storeroom, workshop, supermarket shelves, photovotaic industry, villa, integration wall space, residence, and all kinds of heated housing construction project. Zhengchuang machine can meet growing demand of construction enterprise, auto industry and steel production enterprise.

Contact Supplier

Material and Finish Screw: Hardened carbon Steel,Zinc Plate, chromate plus sealer Ferrule E: Aluminum KNOB(prism plunger ) PC/ABS, black Spring: 300 Se...

Fasten Fix specialized in producing Blind Fasteners, including Rivet Nuts, Rivets, Clinching Fasteners and Welding Studs. With more than 10 years experience in production and exporting, Fasten Fix is a High & New technology enterprise founded in 2003. Wtih two ISO 9001:2009 , TS16949 certified facilities in Shanghai, China. We can manufacture 1.5 billion blind rivets that meet DIN7337 IFI and ISO, GB standards annually. Plus 900 million rivet nuts 120 million of clinching fasteners annually, that most competitors can not simply match. Fasten Fix manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. We focus on “one stop shopping” and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, Fasten FIX has become one of the leading blind fasteners manufacuture & supplier in Asia. We wecome you to contact us, Fasten FIX not only your reliable supplier, but also your turstworthy business partner.

Contact Supplier