- CNC sheetmetal pressbrake with streamlined desigh,hight speed ,hight precision,hight rigidity.

- Electro hydraulic servo system,full loop comtrolling the synchronizatio of the upperbeam.

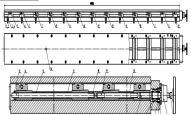

- Equip with hydraulic crowning compensation on worktable and deformation compensation device on throat to make sure bending depth and precision.

- Backgauge is driven bu digital servo motor,moved by ball screw guided by linear guide.

What should we know for choosing a press brake ?

- What’s your material of sheet ?

- What’s the minimum and maximum thickness of your sheet ?

- What’s the minimum and maximum width of your sheet ?

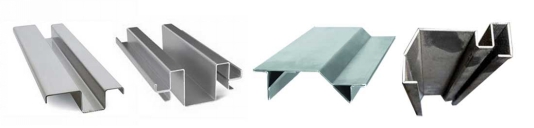

- What kind of product you make ?

- What’s the precision do you require for making products ?

Machine Details:

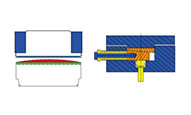

V-axis Table Compensation :

V-axis is the CNC axis to control the adding convex amount of workbench, it can obtain accurate deflection compensation from the workbench. The adding convex workbench is made up of a group of beveled convex wedge, each wedge slope is designed by the deflection curve of finite element analysis of the slider and workbench vertical plate. CNC controller will calculate the required deflection amount according to the load when the work piece is working (The load will lead to the deflection and deformation), automatically control the relative motion of the convex wedge, and finally get an ideal work piece.

| Model | Nominal Pressure(KN) | Length of Table(mm) | Distance between columns(mm) | Throat Depth(mm) | Stroke(mm) | Open Height(mm) | Main Motor(KW) | Overall Dimensions L*W*H(mm) |

|---|---|---|---|---|---|---|---|---|

| 63t/2500 | 630 | 2500 | 2050 | 300 | 150 | 420 | 5.5 | 2700*1700*2300 |

| 63t/3200 | 630 | 3200 | 2700 | 300 | 150 | 420 | 5.5 | 3400*1700*2300 |

| 80t/2500 | 800 | 2500 | 2050 | 300 | 150 | 420 | 5.5 | 2700*1700*2400 |

| 80t/3200 | 800 | 3200 | 2700 | 300 | 150 | 420 | 5.5 | 3400*1700*2400 |

| 100t/3200 | 1000 | 3200 | 2700 | 350 | 180 | 420 | 7.5 | 3400*1800*2600 |

| 100t/4000 | 1000 | 4000 | 3100 | 350 | 180 | 420 | 7.5 | 4200*1800*2600 |

| 125t/3200 | 1250 | 3200 | 2700 | 350 | 200 | 450 | 11 | 3400*1900*2600 |

| 125t/4000 | 1250 | 4000 | 3100 | 350 | 200 | 420 | 11 | 4200*1900*2600 |

| 160t/3200 | 1600 | 3200 | 2700 | 350 | 200 | 450 | 15 | 3400*2000*2800 |

| 160t/4000 | 1600 | 4000 | 3100 | 350 | 200 | 450 | 15 | 4200*2000*2800 |

| 200t/3200 | 2000 | 3200 | 2600 | 400 | 200 | 450 | 18.5 | 3400*2200*2850 |

| 200t/4000 | 2000 | 4000 | 3100 | 400 | 200 | 480 | 18.5 | 4300*2200*2850 |

| 250t/3200 | 2500 | 3200 | 2600 | 400 | 250 | 520 | 22 | 3500*2100*3800 |

| 250t/4000 | 2500 | 4000 | 3150 | 400 | 250 | 520 | 22 | 4200*2100*3800 |

| 250t/5000 | 2500 | 5000 | 3800 | 400 | 250 | 580 | 22 | 5300*2450*4000 |

| 250t/6000 | 2500 | 6000 | 4600 | 400 | 250 | 580 | 22 | 6300*2500*4200 |

| 300t/4000 | 3000 | 4000 | 3200 | 400 | 250 | 580 | 22 | 4300*2500*3900 |

| 300t/5000 | 3000 | 5000 | 4000 | 400 | 250 | 580 | 22 | 5300*2500*4300 |

| 300t/6000 | 3000 | 6000 | 4600 | 400 | 250 | 580 | 22 | 6300*2500*4800 |

| 400t/4000 | 4000 | 4000 | 3200 | 400 | 250 | 580 | 30 | 4200*2700*4200 |

| 400t/5000 | 4000 | 5000 | 4000 | 400 | 250 | 580 | 30 | 5300*2700*4200 |

| 400t/6000 | 4000 | 6000 | 4600 | 400 | 250 | 600 | 30 | 6300*2700*4300 |

| 500t/4000 | 5000 | 4000 | 3200 | 400 | 250 | 600 | 37 | 4300*2700*4200 |

| 500t/5000 | 5000 | 5000 | 4000 | 400 | 250 | 600 | 37 | 5300*2700*4300 |

| 500t/6000 | 5000 | 6000 | 5050 | 400 | 300 | 600 | 37 | 6300*3300*4800 |

| 600t/5000 | 6000 | 5000 | 3800 | 500 | 320 | 640 | 45 | 5300*3300*4500 |

| 600t/6000 | 6000 | 6000 | 5050 | 500 | 320 | 640 | 45 | 6300*3300*5300 |

| 600t/7000 | 6000 | 7000 | 5300 | 500 | 320 | 640 | 45 | 7300*3300*5800 |

| 700t/6000 | 7000 | 6000 | 4900 | 500 | 320 | 700 | 55 | 6300*3500*5500 |

| 800t/6000 | 8000 | 8000 | 4600 | 500 | 320 | 800 | 55 | 6300*3500*6000 |

3+1 Axis ( Y1 Y2 X +V)

Feature :

- Y1 axis sliding piece left cylinder

- Y2 shaft slide right cylinder

- X axis back gauge movement, consists of servo motor, ball screw and rolling guide, control accuracy and high Repeat positioning accuracy

- V axis is Vera control compensation

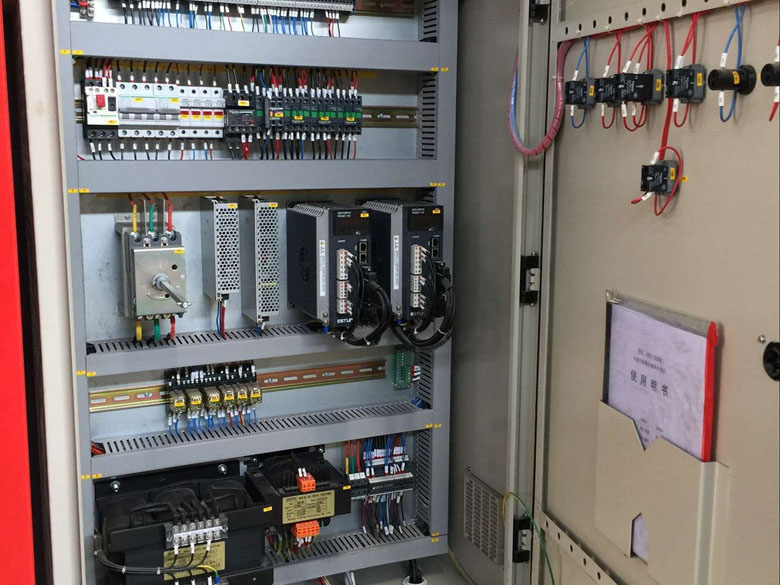

System :

- Delem DA52S CNC

4+1 Axis ( Y1,Y2,X,R +V)

- Y1 axis sliding piece left cylinder

- Y2 shaft slide right cylinder

- X axis back gauge movement, consists of servo motor, ball screw and rolling guide, control accuracy and high Repeat positioning accuracy

- R axis back gauge move up and down

- V axis is Vera control compensation

System :

- Delem DA56 CNC Delem DA52S CNC

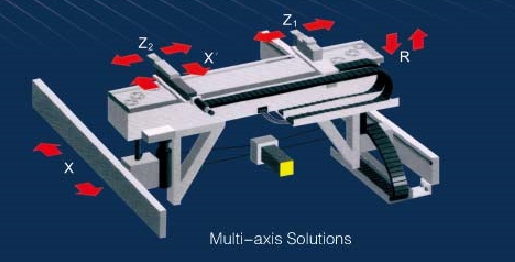

6+1 Axis ( Y1 Y2 X Z1 Z2 R + V) :

About Host Computer

- Y1, Y2 axis at the machine Both ends install two grating ruler, Used to detect the distance of slider and workpiece.

- Grating ruler connected with the worktable, Column deformation does not affect the positioning,

- Location data back to the CNC system after, can measure the output of the servo valve control signal.

- Two grating ruler Full detection, Hydraulic servo valve control, Has strong anti-side load capacity

- X axis consists of servo motor, ball screw and rolling guide, control accuracy and high Repeat positioning accuracy

- Z1, Z2 control back gauge move around

- R axis control lift of back gauge. (up and down )

- V axis is Vera control worktable Convex amount

Systems Options :

8+1 Axis ( Y1 Y2 X1 X2 R1 R2 Z1 Z2 +V)

Structure, Performance:

This machine is Y1, Y2, X1,X2. Z1, Z2, R, V (eight plus one) Electro-hydraulic synchronous CNC machine tools. Adopt steel welded frame、Table structure, Machine use optimized design, High precision, good rigidity, convenient transportation, installation and operation, maintenance, attractive appearance

The main components using UG \ ANSYS \ CAD three-dimensional finite element analysis and design optimization; To ensure that Design aesthetics, structure, reliable, stable;

Hydraulic System :

- Germany BOSCH imported electro-hydraulic servo valve and pressure valve, Compact oil passage structure, high synchronization accuracy, The bottom dead center suspended function; oil pump high pressure oil filter blocking alarm

- Overload safety overflow protection

This machine configuration:

- Control system- Netherlands DELEM-DA66T (Standard)

- Seals, dust ring-Japanese NOK

- Hydraulic parts- Germany Rexroth

- Low noise gear pump- VOITH from U.S.A

- Main Electrical part- Schneider

- Grating ruler-Germany HEIDENHAIN

- Ball screw、linear guide- TaiWan HIWIN

- Molds- standard upper and lower(after heat treatment, all Quenching)

- Front and rear safety guards, Photoelectric protection can be optional

DA66T STANDARD SYSTEM