ADH Machine Tool is a professional manufacturer of bending machine, shearing machine, Our company is in the production of large bending machine, shearing machine ranked in the top five companies in the Domestic.the factory located in China. The registered capital is 33.8 million yuan. Annual production capacity of equipment is more than 5000 sets, assets more than 300 million. Our company is in strict accordance with the ISO9001:2008 international quality system to manage.product passed CE certification,Germany TUV certification and CQC China quality certification. We have 3 independent invention patents, 28 new patents. Donghai Machine Tool Co.,Ltd not only can meet special requirement of our customer, but also make personalized sheet metal processing equipment. So far,our products has sold to Europe (Russia,Poland, Germany,Ukraine) South America(Colombia, Argentina, Chile, Brazil, Peru)Middle East and Southeast Asia(India, Saudi Arabia, Egypt, Iran, Israel, Malaysia and Vietnam and so on).

-

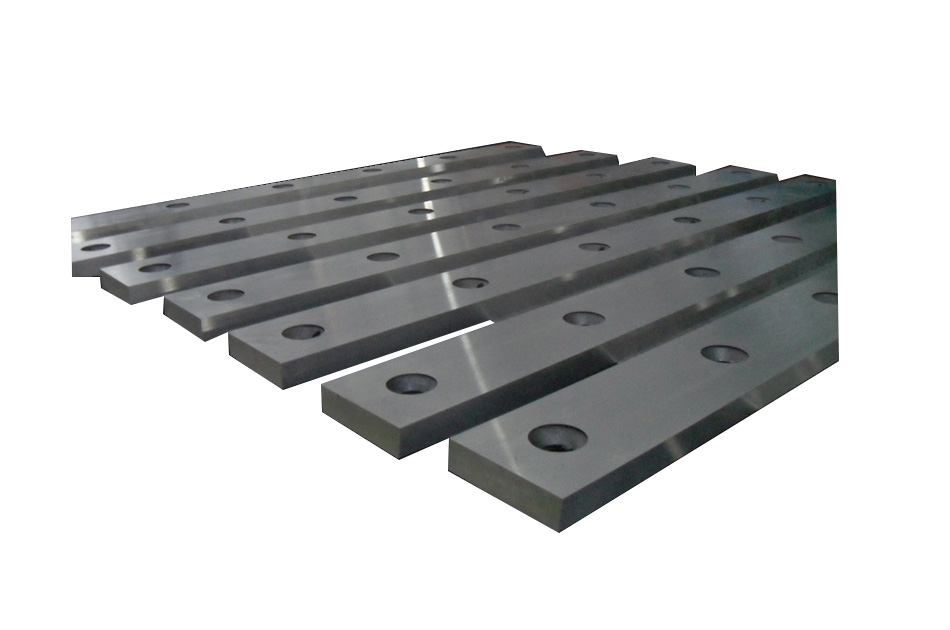

Shearing Blades

The blades are set on the shearing machine and used to cut the metal sheet.The material of the blade can be 9CrSi,6CrW2Si,Cr12MoV,H13 and so on.Different material blades deal with different material metal.Such as the product material is stainless steel,you can choose blade material 6CrW2Si or H13.

-

Special Industry and Required Shear

1.QS12K HYDRAULIC SWING SHEARING MACHINE WITH PRE-FEEDING This model is the upgrades of QC12K,not only with CNC controller,also set with pre-feeding device. This kind of shear will come with DAC310 CNC controller to drive the pre-feeding device instead of the back gauge,it increases the cutting ac

- Contacter: Helen Sun

- Tel: 0086-555-6760666

- Fax: 0086-555-6767077

- Email: sales@adhmt.com

-

Company Address:

Bowang Industrial Zone Ma\'anshan City, China

Shearing Blades

The blades are set on the shearing machine and used to cut the metal sheet.The material of the blade can be 9CrSi,6CrW2Si,Cr12MoV,H13 and so on.Different material blades deal with different material metal.Such as the product material is stainless steel,you can choose blade material 6CrW2Si or H13.

Shearing Blades

The blades are set on the shearing machine and used to cut the metal sheet.The material of the blade can be 9CrSi,6CrW2Si,Cr12MoV,H13 and so on.Different material blades deal with different material metal.Such as the product material is stainless steel,you can choose blade material 6CrW2Si or H13.

Special Industry and Required Shear

1.QS12K HYDRAULIC SWING SHEARING MACHINE WITH PRE-FEEDING

This model is the upgrades of QC12K,not only with CNC controller,also set with pre-feeding device.

This kind of shear will come with DAC310 CNC controller to drive the pre-feeding device instead of the back gauge,it increases the cutting accuracy and working efficiency.The pre-feeding device is controlled by the CNC controller and it is set with automatic pneumatic clamps and feeding system,helps to save labor and time.

The size can be designed according to customers’ real requirement.

This model is usually used for thin and precision product sheet.

2.QS11K HYDRAULIC GUILLOTINE SHEARING MACHINE WITH PRE-FEEDING

This model is the upgrades of Q11K,together with CNC controller and pre-feeding device.

This kind of shear will come with DAC360 CNC controller to drive the pre-feeding device instead of the back gauge,it increases the cutting accuracy and working efficiency.The pre-feeding device is controlled by the CNC controller and it is set with automatic pneumatic clamps and feeding system,helps to save labor and time.

The size can be designed according to customers’ real requirement.

This model is usually used for thick plate.

3.LARGE CNC SHEARING MACHINE

Usually the length of the shearing machine is over 6000mm,such as 6000mm,8000mm,10000mm.And the length can be designed according to customer’s requirement.This kind of large CNC shearing machine is widely used in auto industry,construction machinery,sometimes used in the other industries.

The kind of large shear is with steel welded structure,hydraulic transmission,accumulator return.

Special Industry and Required Shear

1.QS12K HYDRAULIC SWING SHEARING MACHINE WITH PRE-FEEDING

This model is the upgrades of QC12K,not only with CNC controller,also set with pre-feeding device.

This kind of shear will come with DAC310 CNC controller to drive the pre-feeding device instead of the back gauge,it increases the cutting accuracy and working efficiency.The pre-feeding device is controlled by the CNC controller and it is set with automatic pneumatic clamps and feeding system,helps to save labor and time.

The size can be designed according to customers’ real requirement.

This model is usually used for thin and precision product sheet.

2.QS11K HYDRAULIC GUILLOTINE SHEARING MACHINE WITH PRE-FEEDING

This model is the upgrades of Q11K,together with CNC controller and pre-feeding device.

This kind of shear will come with DAC360 CNC controller to drive the pre-feeding device instead of the back gauge,it increases the cutting accuracy and working efficiency.The pre-feeding device is controlled by the CNC controller and it is set with automatic pneumatic clamps and feeding system,helps to save labor and time.

The size can be designed according to customers’ real requirement.

This model is usually used for thick plate.

3.LARGE CNC SHEARING MACHINE

Usually the length of the shearing machine is over 6000mm,such as 6000mm,8000mm,10000mm.And the length can be designed according to customer’s requirement.This kind of large CNC shearing machine is widely used in auto industry,construction machinery,sometimes used in the other industries.

The kind of large shear is with steel welded structure,hydraulic transmission,accumulator return.

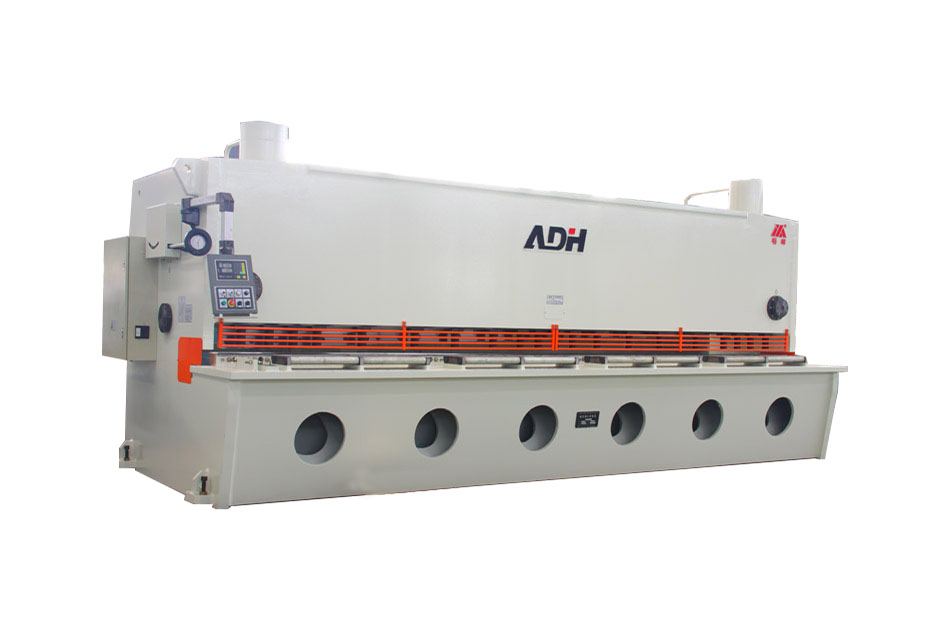

Q11K Series Hydraulic CNC Guillotine Shearing Machine

This series is the upgrades of the Q11Y series.It will come with Computer Numerical Control(CNC) operation system and ball screw,linear guide and servo motor driven back gauge to ensure the position accuracy.The blades for this series have 4 edges using,easy to change the blades.

Performance characteristics:

1.Integrated steel welded structure,eliminate stress by vibration,with good rigidity.

2.Optional China famous CNC E200PS or Netherlands DELEM DAC360 CNC controller

3.System controlled back gauge and cutting angle and stroke

4.Adopt ball screw,linear guide and servo motor to drive the back gauge with high positioning accuracy

5.Serial linked oil cylinder,so the cutting angle will not change during the operation of the shearing machine

6.With smoothly and swift accumulator return

7.Automatically adjustment of the blade gap,precise,rapid and convenient

8.Adjustable cutting angle to minimize distortion of the plate

9.Motorized back gauge,position display to improve its precision

10.Ball rolling front support in order to minimize scuffing as well as friction resistance

Our machine advantages:

1.Blade rest adopt centroid design,it is well improved the shear surface vertical degree.

In the same industry:In order to reduce the cost,they used to adopt graphic design,the machine can not guarantee that the shear surface vertical degree.

2.Adopt three pivot wheel design,make full use of the lever principle,three pivot distance design reasonable practical,to ensure the quality of the shear face,to ensure the quality of the shear face.

In the same industry:The design of the three pivot without using the lever principle,the distance protection, size is consistent,easy to make the product vertical pivot too much stress and fracture.

3.Shear rate meet 50-60 mm/sec at a faster rate than the same industry products,improve the work efficiency, reduce production costs.

In the same industry:20-30mm/sec

4.Back gauge baffle can make minor adjustments (manual), to avoid the size error, affect the production efficiency.

5.Back gauge baffle and blade rest adopt ball connection,so that parallelism can be adjusted with the lower blade and baffle.

In the same industry:Two design together directly,it is difficult to adjust blade clearance when back gauge causes the error.

6.The blade supporting of worktable is designed humanization,easy to adjust the uniformity of the blade clearance and blade gap.

7.The back fulcrum at the bottom adopts bias shaft design,adjustable the left and right straightness of blade rest to ensure to parallel with bottom blade.

How to choose the machine model?

The main required information is the material,cutting thickness and cutting length.

This series shear is mainly used to cut metal plates with the thickness of 1-50mm and different shearing length.The maximum cutting thickness is only applicable to carbon structural steel plates with the tensile strength of 450 MPa; if it is used to cut metal plates with relatively high tensile strength such as manganese steel, stainless steel, etc., the maximum shearing thickness shall be less. Thus, when using the shear, the thickness of plates shall be strictly controlled by the operators themselves in accordance with the value of tensile strength of plates.The cutting angle of this series is adjustable,it can be adjusted according to different thickness,usually it is widely used for the thickness above 12mm.And usually length is ≥6000mm,this series will be chosen.

Then,according to the thickness of different material,you can choose the suitable length for yourself.With all of these you can go to the technical parameters table to find the right model and details.

If you need further help from us,please contact us through our contact information.

Q11K Series Hydraulic CNC Guillotine Shearing Machine

This series is the upgrades of the Q11Y series.It will come with Computer Numerical Control(CNC) operation system and ball screw,linear guide and servo motor driven back gauge to ensure the position accuracy.The blades for this series have 4 edges using,easy to change the blades.

Performance characteristics:

1.Integrated steel welded structure,eliminate stress by vibration,with good rigidity.

2.Optional China famous CNC E200PS or Netherlands DELEM DAC360 CNC controller

3.System controlled back gauge and cutting angle and stroke

4.Adopt ball screw,linear guide and servo motor to drive the back gauge with high positioning accuracy

5.Serial linked oil cylinder,so the cutting angle will not change during the operation of the shearing machine

6.With smoothly and swift accumulator return

7.Automatically adjustment of the blade gap,precise,rapid and convenient

8.Adjustable cutting angle to minimize distortion of the plate

9.Motorized back gauge,position display to improve its precision

10.Ball rolling front support in order to minimize scuffing as well as friction resistance

Our machine advantages:

1.Blade rest adopt centroid design,it is well improved the shear surface vertical degree.

In the same industry:In order to reduce the cost,they used to adopt graphic design,the machine can not guarantee that the shear surface vertical degree.

2.Adopt three pivot wheel design,make full use of the lever principle,three pivot distance design reasonable practical,to ensure the quality of the shear face,to ensure the quality of the shear face.

In the same industry:The design of the three pivot without using the lever principle,the distance protection, size is consistent,easy to make the product vertical pivot too much stress and fracture.

3.Shear rate meet 50-60 mm/sec at a faster rate than the same industry products,improve the work efficiency, reduce production costs.

In the same industry:20-30mm/sec

4.Back gauge baffle can make minor adjustments (manual), to avoid the size error, affect the production efficiency.

5.Back gauge baffle and blade rest adopt ball connection,so that parallelism can be adjusted with the lower blade and baffle.

In the same industry:Two design together directly,it is difficult to adjust blade clearance when back gauge causes the error.

6.The blade supporting of worktable is designed humanization,easy to adjust the uniformity of the blade clearance and blade gap.

7.The back fulcrum at the bottom adopts bias shaft design,adjustable the left and right straightness of blade rest to ensure to parallel with bottom blade.

How to choose the machine model?

The main required information is the material,cutting thickness and cutting length.

This series shear is mainly used to cut metal plates with the thickness of 1-50mm and different shearing length.The maximum cutting thickness is only applicable to carbon structural steel plates with the tensile strength of 450 MPa; if it is used to cut metal plates with relatively high tensile strength such as manganese steel, stainless steel, etc., the maximum shearing thickness shall be less. Thus, when using the shear, the thickness of plates shall be strictly controlled by the operators themselves in accordance with the value of tensile strength of plates.The cutting angle of this series is adjustable,it can be adjusted according to different thickness,usually it is widely used for the thickness above 12mm.And usually length is ≥6000mm,this series will be chosen.

Then,according to the thickness of different material,you can choose the suitable length for yourself.With all of these you can go to the technical parameters table to find the right model and details.

If you need further help from us,please contact us through our contact information.

Q11Y Series Hydraulic NC Guillotine Shearing Machine

This series Q11Y hydraulic shearing machine adopts the function of cutting angle adjustment device to feet with different thickness plates.The working principle of this series is guillotine cutting type.The blades for this series have 4 edges using,easy to change the blades.

Performance characteristics:

1.Integrated steel welded structure,eliminate stress by vibration,with good rigidity.

2.Adopt advanced hydraulic integrated valve unit with compact structure,minimized pipe connection,in order to improve the reliability of the system and easy for maintain

3.Serial linked oil cylinder,so the cutting angle will not change during the operation of the shearing machine

4.With smoothly and swift accumulator return

5.Automatically adjustment of the blade gap,precise,rapid and convenient

6.Adjustable cutting angle to minimize distortion of the plate

7.Motorized back gauge,position display to improve its precision

8.Ball rolling front support in order to minimize scuffing as well as friction resistance

Our machine advantages:

1.Blade rest adopt centroid design,it is well improved the shear surface vertical degree.

In the same industry:In order to reduce the cost,they used to adopt graphic design,the machine can not guarantee that the shear surface vertical degree.

2.Adopt three pivot wheel design,make full use of the lever principle,three pivot distance design reasonable practical,to ensure the quality of the shear face,to ensure the quality of the shear face.

In the same industry:The design of the three pivot without using the lever principle,the distance protection, size is consistent,easy to make the product vertical pivot too much stress and fracture.

3.Shear rate meet 50-60 mm/sec at a faster rate than the same industry products,improve the work efficiency, reduce production costs.

In the same industry:20-30mm/sec

4.Back gauge baffle can make minor adjustments (manual), to avoid the size error, affect the production efficiency.

5.Back gauge baffle and blade rest adopt ball connection,so that parallelism can be adjusted with the lower blade and baffle.

In the same industry:Two design together directly,it is difficult to adjust blade clearance when back gauge causes the error.

6.The blade supporting of worktable is designed humanization,easy to adjust the uniformity of the blade clearance and blade gap.

7.The back fulcrum at the bottom adopts bias shaft design,adjustable the left and right straightness of blade rest to ensure to parallel with bottom blade.

How to choose the machine model?

The main required information is the material,cutting thickness and cutting length.

This series shear is mainly used to cut metal plates with the thickness of 1-50mm and different shearing length.The maximum cutting thickness is only applicable to carbon structural steel plates with the tensile strength of 450 MPa; if it is used to cut metal plates with relatively high tensile strength such as manganese steel, stainless steel, etc., the maximum shearing thickness shall be less. Thus, when using the shear, the thickness of plates shall be strictly controlled by the operators themselves in accordance with the value of tensile strength of plates.The cutting angle of this series is adjustable,it can be adjusted according to different thickness,usually it is widely used for the thickness above 12mm.And usually length is ≥6000mm,this series will be chosen.

Then,according to the thickness of different material,you can choose the suitable length for yourself.With all of these you can go to the technical parameters table to find the right model and details.

If you need further help from us,please contact us through our contact information.

Q11Y Series Hydraulic NC Guillotine Shearing Machine

This series Q11Y hydraulic shearing machine adopts the function of cutting angle adjustment device to feet with different thickness plates.The working principle of this series is guillotine cutting type.The blades for this series have 4 edges using,easy to change the blades.

Performance characteristics:

1.Integrated steel welded structure,eliminate stress by vibration,with good rigidity.

2.Adopt advanced hydraulic integrated valve unit with compact structure,minimized pipe connection,in order to improve the reliability of the system and easy for maintain

3.Serial linked oil cylinder,so the cutting angle will not change during the operation of the shearing machine

4.With smoothly and swift accumulator return

5.Automatically adjustment of the blade gap,precise,rapid and convenient

6.Adjustable cutting angle to minimize distortion of the plate

7.Motorized back gauge,position display to improve its precision

8.Ball rolling front support in order to minimize scuffing as well as friction resistance

Our machine advantages:

1.Blade rest adopt centroid design,it is well improved the shear surface vertical degree.

In the same industry:In order to reduce the cost,they used to adopt graphic design,the machine can not guarantee that the shear surface vertical degree.

2.Adopt three pivot wheel design,make full use of the lever principle,three pivot distance design reasonable practical,to ensure the quality of the shear face,to ensure the quality of the shear face.

In the same industry:The design of the three pivot without using the lever principle,the distance protection, size is consistent,easy to make the product vertical pivot too much stress and fracture.

3.Shear rate meet 50-60 mm/sec at a faster rate than the same industry products,improve the work efficiency, reduce production costs.

In the same industry:20-30mm/sec

4.Back gauge baffle can make minor adjustments (manual), to avoid the size error, affect the production efficiency.

5.Back gauge baffle and blade rest adopt ball connection,so that parallelism can be adjusted with the lower blade and baffle.

In the same industry:Two design together directly,it is difficult to adjust blade clearance when back gauge causes the error.

6.The blade supporting of worktable is designed humanization,easy to adjust the uniformity of the blade clearance and blade gap.

7.The back fulcrum at the bottom adopts bias shaft design,adjustable the left and right straightness of blade rest to ensure to parallel with bottom blade.

How to choose the machine model?

The main required information is the material,cutting thickness and cutting length.

This series shear is mainly used to cut metal plates with the thickness of 1-50mm and different shearing length.The maximum cutting thickness is only applicable to carbon structural steel plates with the tensile strength of 450 MPa; if it is used to cut metal plates with relatively high tensile strength such as manganese steel, stainless steel, etc., the maximum shearing thickness shall be less. Thus, when using the shear, the thickness of plates shall be strictly controlled by the operators themselves in accordance with the value of tensile strength of plates.The cutting angle of this series is adjustable,it can be adjusted according to different thickness,usually it is widely used for the thickness above 12mm.And usually length is ≥6000mm,this series will be chosen.

Then,according to the thickness of different material,you can choose the suitable length for yourself.With all of these you can go to the technical parameters table to find the right model and details.

If you need further help from us,please contact us through our contact information.

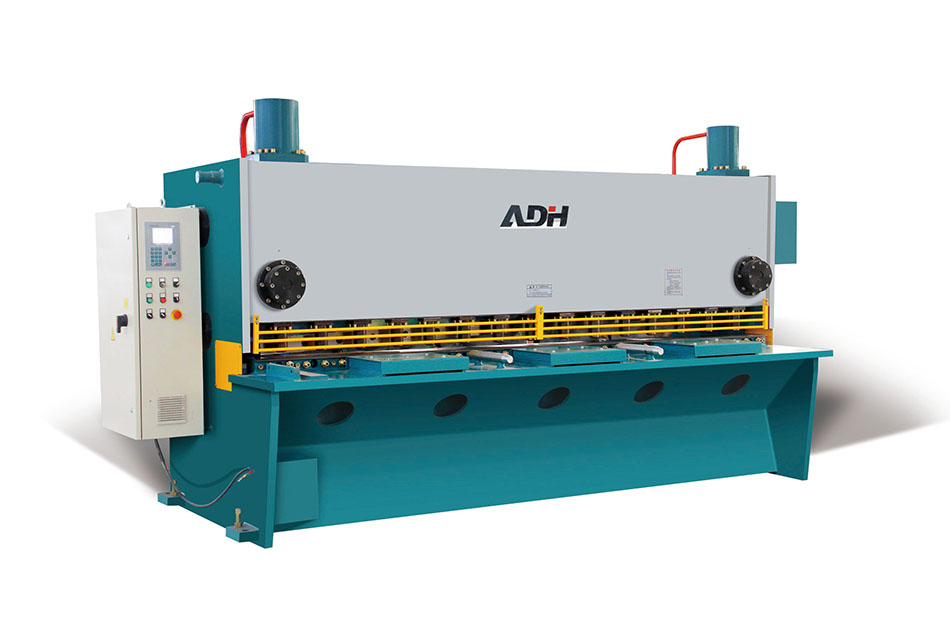

QC12K Series Hydraulic CNC Swing Shearing Machine

This series shearing machine is the upgrades of QC12Y series.It will come with Computer Numerical Control(CNC) operation system and ball screw,linear guide and servo motor driven back gauge to ensure the position accuracy.

Performance characteristics:

1.With optional programmed controller system Chinese famous ESTUN E200PS or Netherlands DELEM DAC310

2.Adopt linear guide,ball screw and servo motor driven back gauge to ensure the accuracy

3.All main parts of this machine such as worktable, wallboard,top blade rest, etc. are adopting steel plate welded structure

4.Hydraulic transmission cutting,

5.Nitrogen cylinder driven returning stroke with stable operation, low noise, and well rigidity

6.With electric driven back stop structure and mechanical worm wheel-worm transmission control with low noise and high precision

7.Adjustment blade gap board to adapt different thickness plates

8.Safety protection fence and warning tape

Our machine advantages:

1)Straightness:Within 3 meter error within 0.10mm

In the same industry product error 0.5-1mm

2)Cutting times 50% faster than the same industry.

For example:4*2500 shearing machine,our company product 30 times/min,in the same industry product only 12 times/min.

3)Machine body intensity,high precision processing equipment,holistic processing,the machine body will not be deformation in 10 years.

4)Blade material:6CrW2Si

Heat treatment: 55°-60°HB

5)Low noise,gear pump drive by hydraulic,70bd.

6)Emergency stop foot pedal increase the security protection,explosion -proof power supply switch cord.

How to choose the machine model?

The main required information is the material,cutting thickness and cutting length.

This series shear is mainly used to cut metal plates with the thickness of 0.2-30mm and different shearing length.The maximum cutting thickness is only applicable to carbon structural steel plates with the tensile strength of 450 MPa; if it is used to cut metal plates with relatively high tensile strength such as manganese steel, stainless steel, etc., the maximum shearing thickness shall be less. Thus, when using the shear, the thickness of plates shall be strictly controlled by the operators themselves in accordance with the value of tensile strength of plates.As the cutting angle of this series is fixed,it can not be adjusted according to big thickness difference,usually it is widely used with the thickness of 0.2-16mm.Above 16mm thickness you can choose Q11Y series.

Then,according to the thickness of different material,you can choose the suitable length for yourself.With all of these you can go to the technical parameters table to find the right model and details.

If you need further help from us,please contact us through our contact information.

QC12K Series Hydraulic CNC Swing Shearing Machine

This series shearing machine is the upgrades of QC12Y series.It will come with Computer Numerical Control(CNC) operation system and ball screw,linear guide and servo motor driven back gauge to ensure the position accuracy.

Performance characteristics:

1.With optional programmed controller system Chinese famous ESTUN E200PS or Netherlands DELEM DAC310

2.Adopt linear guide,ball screw and servo motor driven back gauge to ensure the accuracy

3.All main parts of this machine such as worktable, wallboard,top blade rest, etc. are adopting steel plate welded structure

4.Hydraulic transmission cutting,

5.Nitrogen cylinder driven returning stroke with stable operation, low noise, and well rigidity

6.With electric driven back stop structure and mechanical worm wheel-worm transmission control with low noise and high precision

7.Adjustment blade gap board to adapt different thickness plates

8.Safety protection fence and warning tape

Our machine advantages:

1)Straightness:Within 3 meter error within 0.10mm

In the same industry product error 0.5-1mm

2)Cutting times 50% faster than the same industry.

For example:4*2500 shearing machine,our company product 30 times/min,in the same industry product only 12 times/min.

3)Machine body intensity,high precision processing equipment,holistic processing,the machine body will not be deformation in 10 years.

4)Blade material:6CrW2Si

Heat treatment: 55°-60°HB

5)Low noise,gear pump drive by hydraulic,70bd.

6)Emergency stop foot pedal increase the security protection,explosion -proof power supply switch cord.

How to choose the machine model?

The main required information is the material,cutting thickness and cutting length.

This series shear is mainly used to cut metal plates with the thickness of 0.2-30mm and different shearing length.The maximum cutting thickness is only applicable to carbon structural steel plates with the tensile strength of 450 MPa; if it is used to cut metal plates with relatively high tensile strength such as manganese steel, stainless steel, etc., the maximum shearing thickness shall be less. Thus, when using the shear, the thickness of plates shall be strictly controlled by the operators themselves in accordance with the value of tensile strength of plates.As the cutting angle of this series is fixed,it can not be adjusted according to big thickness difference,usually it is widely used with the thickness of 0.2-16mm.Above 16mm thickness you can choose Q11Y series.

Then,according to the thickness of different material,you can choose the suitable length for yourself.With all of these you can go to the technical parameters table to find the right model and details.

If you need further help from us,please contact us through our contact information.

QC12Y Series Hydraulic NC Swing Shearing Machine

General instruction:

Easy-controlled digital display panel,stable structure with low noise cutting,it can cutting minimum thickness up to 0.2mm and it is with blade gap adjustment for different thickness plates.Most cost-effective shearing machine.

Performance characteristics:

1.With optional simple display MD11 and E21S controller,easy and visual operation

2.All main parts of this machine such as worktable, wallboard,top blade rest, etc. are adopting steel plate welded structure

3.Hydraulic transmission cutting,

4.Nitrogen cylinder driven returning stroke with stable operation, low noise, and well rigidity

5.With electric driven back stop structure and mechanical worm wheel-worm transmission control with low noise and high precision

6.Adjustment blade gap board to adapt different thickness plates

7.Safety protection fence and warning tape

Our machine advantages:

1)Straightness:Within 3 meter error within 0.10mm

In the same industry product error 0.5-1mm

2)Cutting times 50% faster than the same industry.

For example:4*2500 shearing machine,our company product 30 times/min,in the same industry product only 12 times/min.

3)Machine body intensity,high precision processing equipment,holistic

processing,the machine body will not be deformation in 10 years.

4)Blade material:6CrW2Si

Heat treatment: 55°-60°HB

5)Low noise,gear pump drive by hydraulic,70bd.

6)Emergency stop foot pedal increase the security protection,explosion -proof power supply switch cord.

How to choose the machine model?

The main required information is the material,cutting thickness and cutting length.

This series shear is mainly used to cut metal plates with the thickness

of 0.2-30mm and different shearing length.The maximum cutting thickness

is only applicable to carbon structural steel plates with the tensile

strength of 450 MPa; if it is used to cut metal plates with relatively

high tensile strength such as manganese steel, stainless steel, etc.,

the maximum shearing thickness shall be less. Thus, when using the

shear, the thickness of plates shall be strictly controlled by the

operators themselves in accordance with the value of tensile strength of

plates.As the cutting angle of this series is fixed,it can not

be adjusted according to big thickness difference,usually it is widely

used with the thickness of 0.2-16mm.Above 16mm thickness you can choose

Q11Y series.

Then,according to the thickness of different

material,you can choose the suitable length for yourself.With all of

these you can go to the technical parameters table to find the right

model and details.

If you need further help from us,please contact us through our contact information.

QC12Y Series Hydraulic NC Swing Shearing Machine

General instruction:

Easy-controlled digital display panel,stable structure with low noise cutting,it can cutting minimum thickness up to 0.2mm and it is with blade gap adjustment for different thickness plates.Most cost-effective shearing machine.

Performance characteristics:

1.With optional simple display MD11 and E21S controller,easy and visual operation

2.All main parts of this machine such as worktable, wallboard,top blade rest, etc. are adopting steel plate welded structure

3.Hydraulic transmission cutting,

4.Nitrogen cylinder driven returning stroke with stable operation, low noise, and well rigidity

5.With electric driven back stop structure and mechanical worm wheel-worm transmission control with low noise and high precision

6.Adjustment blade gap board to adapt different thickness plates

7.Safety protection fence and warning tape

Our machine advantages:

1)Straightness:Within 3 meter error within 0.10mm

In the same industry product error 0.5-1mm

2)Cutting times 50% faster than the same industry.

For example:4*2500 shearing machine,our company product 30 times/min,in the same industry product only 12 times/min.

3)Machine body intensity,high precision processing equipment,holistic

processing,the machine body will not be deformation in 10 years.

4)Blade material:6CrW2Si

Heat treatment: 55°-60°HB

5)Low noise,gear pump drive by hydraulic,70bd.

6)Emergency stop foot pedal increase the security protection,explosion -proof power supply switch cord.

How to choose the machine model?

The main required information is the material,cutting thickness and cutting length.

This series shear is mainly used to cut metal plates with the thickness

of 0.2-30mm and different shearing length.The maximum cutting thickness

is only applicable to carbon structural steel plates with the tensile

strength of 450 MPa; if it is used to cut metal plates with relatively

high tensile strength such as manganese steel, stainless steel, etc.,

the maximum shearing thickness shall be less. Thus, when using the

shear, the thickness of plates shall be strictly controlled by the

operators themselves in accordance with the value of tensile strength of

plates.As the cutting angle of this series is fixed,it can not

be adjusted according to big thickness difference,usually it is widely

used with the thickness of 0.2-16mm.Above 16mm thickness you can choose

Q11Y series.

Then,according to the thickness of different

material,you can choose the suitable length for yourself.With all of

these you can go to the technical parameters table to find the right

model and details.

If you need further help from us,please contact us through our contact information.