| SN | Name | Process Index | Remark |

|---|---|---|---|

| 1 | Paraformaldehyde content | 93-96%w/w | Normally96% |

| 2 | Formic acid | <0.03% | |

| 3 | Melting range | 120-170℃ | |

| 4 | Ash content | <100ppm | |

| 5 | Appearance | White powder | |

| 6 | Methanol content | <1wt% | |

| 7 | Free water | <1wt% | |

| 8 | Iron content | <2ppm |

Paraformaldehyde plant( as per 93%-96%)Consumption index

| No. | Item | Specification | Unit | Jiangsu Kaimao |

|---|---|---|---|---|

| 1 | Methanol | Pure99.5% | kg/t | ≤1280(including dilute formaldehyde) |

| 2 | Steam | 0.4MPA | kg/t | ≤2,250 |

| 3 | Electricity | 380V | kWh/t | ≤130 |

| 4 | Dilute formaldehyde | (19~22%) | kg/t | -2,200 |

| 5 | Circulating water | 30~38 | m3/h | 400 |

| project | Types and parameters | Number of Production line | Finish Date |

|---|---|---|---|

| Hebei Jizhou Yinhe Chemical LLC. |

50000tpa formaldehyde plant 5000pta paraformaldehyde plant |

2 | 2007.1 |

| Hebei province Xinle City Yongxing Chemical Plant |

50000tpa formaldehyde plant 5000pta paraformaldehyde plant |

2 | 2007.4 |

| Hebei Jingtaida Chemical Co. Ltd. | 20000tpa paraformaldehyde plant | 1 | 2013.3 |

| Hebei Yuhang Chemical Co. Ltd. | 3000tpa paraformaldehyde plant | 1 | 2013.1 |

|

Leshan Fuhua Tongda Pesticide technology Co., Ltd. Leshan Hongya Chemical Co. Ltd. |

240000tpa formaldehyde plant and 60000tpa paraformaldehyde plant | 4 | 2013.4 |

| Hebei Yuhang Chemical Co. Ltd. | paraformaldehyde plant and instrument | 1 | 2014.12 |

Overview - Vacuum Rake Dryer Process

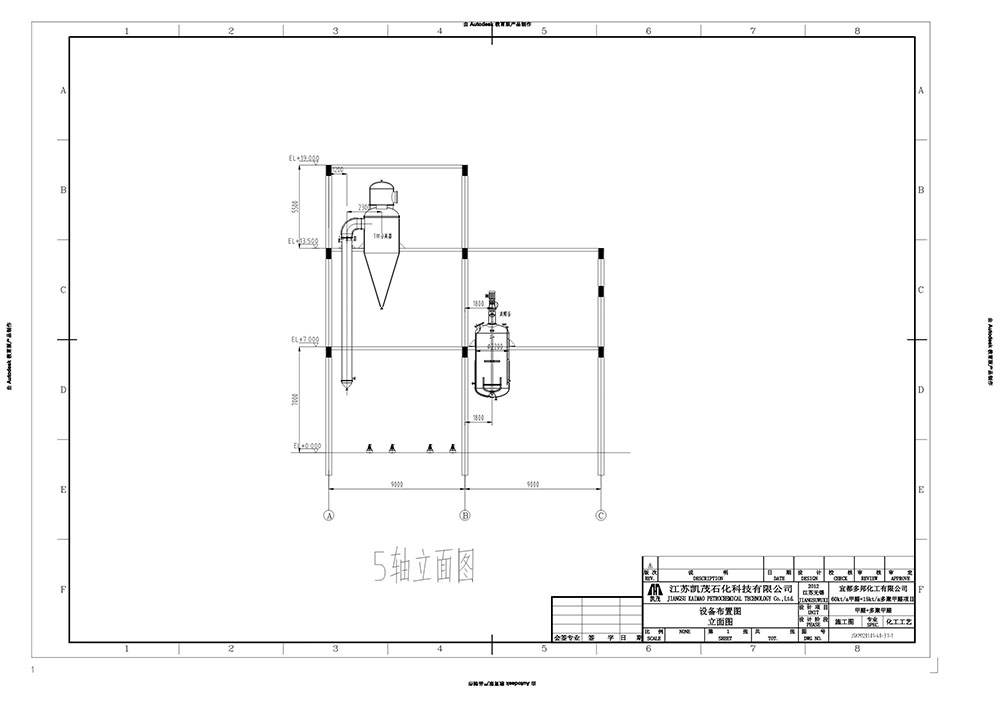

Formaldehyde (HCHO) is with chemical activity and strong reaction capacity, and it can have reaction with acetic acid and Propanoic acid, making important chemical intermediates, such as acrylic acid and methacrylic acid. HO(CH20)nH is the product formed from formaldehyde solution dehydration and condensation. It is divided into 2 kinds, including paraformaldehyde with low polymerization degree (polymerization N is 2-8) and paraformaldehyde(polymerization N is 8-100). Paraformaldehyde is the solid powder, convenient for storage and transportation, and it is widely applied in chemical compounds and other industrial field such as chemistry and pharmacy, it is the excellent replacement for industrial formaldehyde. But paraformaldehyde itself has no chemical activity. Only by depolymerizing paraformaldehyde into single formaldehyde, can it be used for reaction. In addition, in the storage process, formaldehyde can be easily polymerized, and it has to be depolymerized for being taken full use of.Rake vacuum dryer process for paraformaldehyde is the traditional paraformaldehyde production process. It is with advantage of simple process and less investment, but it has big steam consumption.

The paraformaldehyde plant with rake dryer process is diffident with the traditional process. Firstly, the first-efficiency condensation is adopted to condensate the 50% formaldehyde to 75%, and then pumped into rake dryer for drying. One concentrator can be matched with 20 rake dryers for the most.

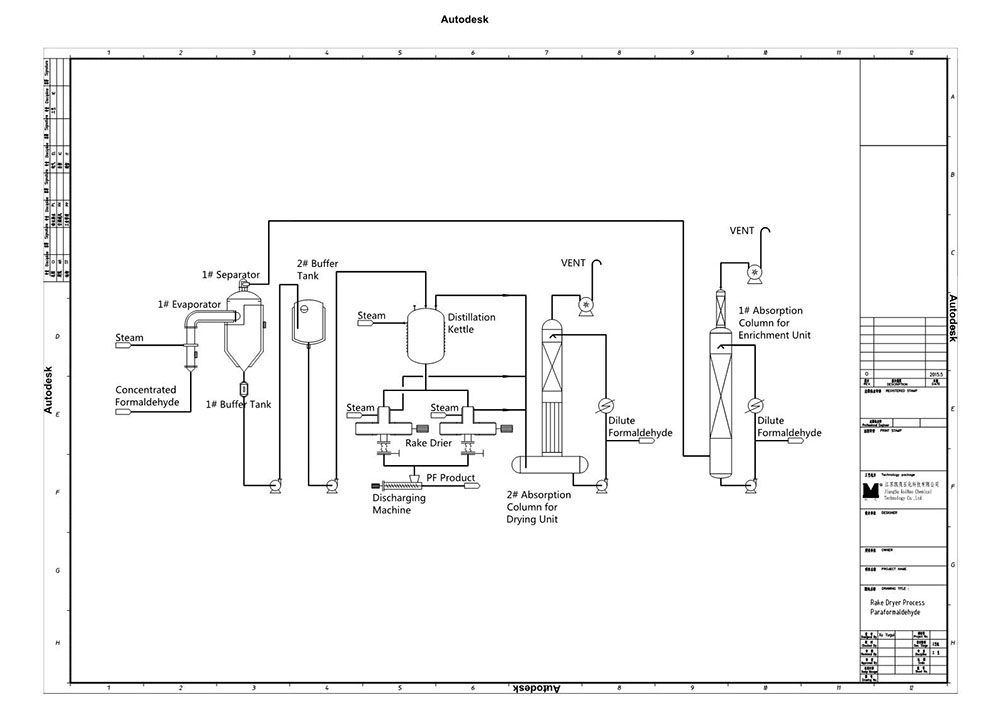

1、The brief introduction of vacuum rake dryer process:

(1).First-efficiency condensation

First-efficiency condensation: 50%-55% formaldehyde solution comes from the bottom of the first- efficiency evaporator; the theory for first-efficiency evaporator is climbing film evaporation. With the certain temperature controlled in the first-efficiency evaporator, and the pressure controlled to be negative pressure, the created gas phase and liquid phase material come together into first-efficiency evaporator for vacuum liquid-gas separation (pressure is the negative pressure), the gas is the mixed gas of water and formaldehyde steam, and it comes to condensation absorber for absorption, getting the dilute formaldehyde solution. The condensate formaldehyde solution via formaldehyde pump, is put into distillation kettle.

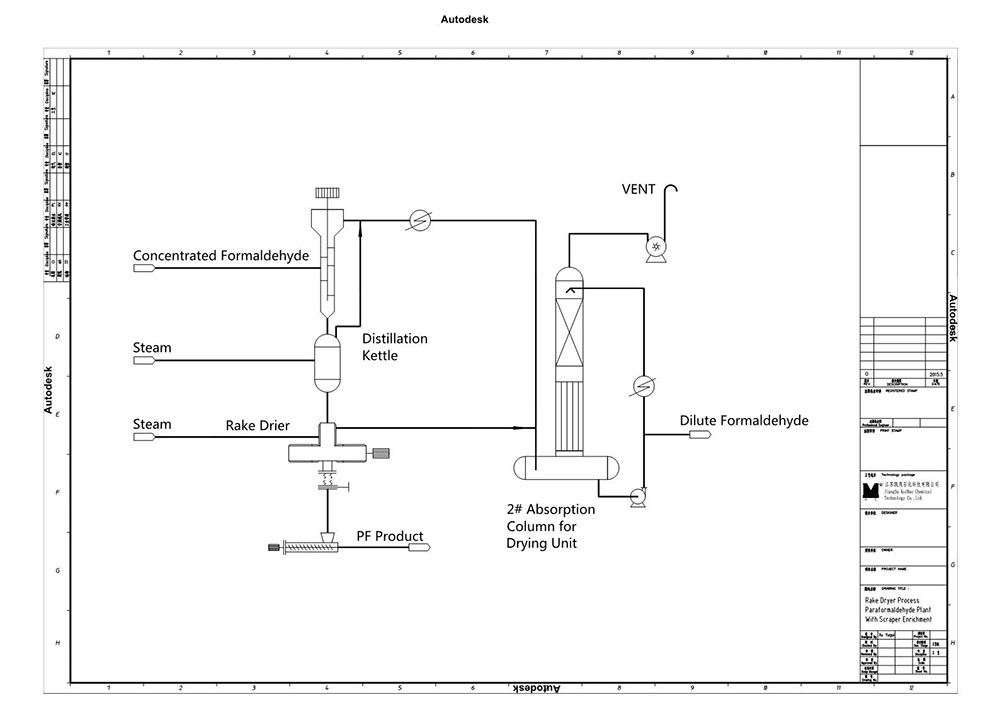

The above adopted condensation section refers to the spray dryer process for paraformaldehyde of our company, which is very advanced. For the special clients, we can also supply with the traditional scraper condensation.

Scraper condensation: 50%~ 55% formaldehyde solution is pumped into scraper concentrator, condensed under the condition of vacuum. The concentrated formaldehyde takes use of gravity and comes into distillation kettle. Steam is inlet to the coil of the distillation kettle for re-evaporation and condensation in Vacuum, getting concentrated formaldehyde. The scraper condenser and distillation kettle are all operated under condition of negative pressure, getting the gas-liquid mixture, coming into drying absorber for absorption.

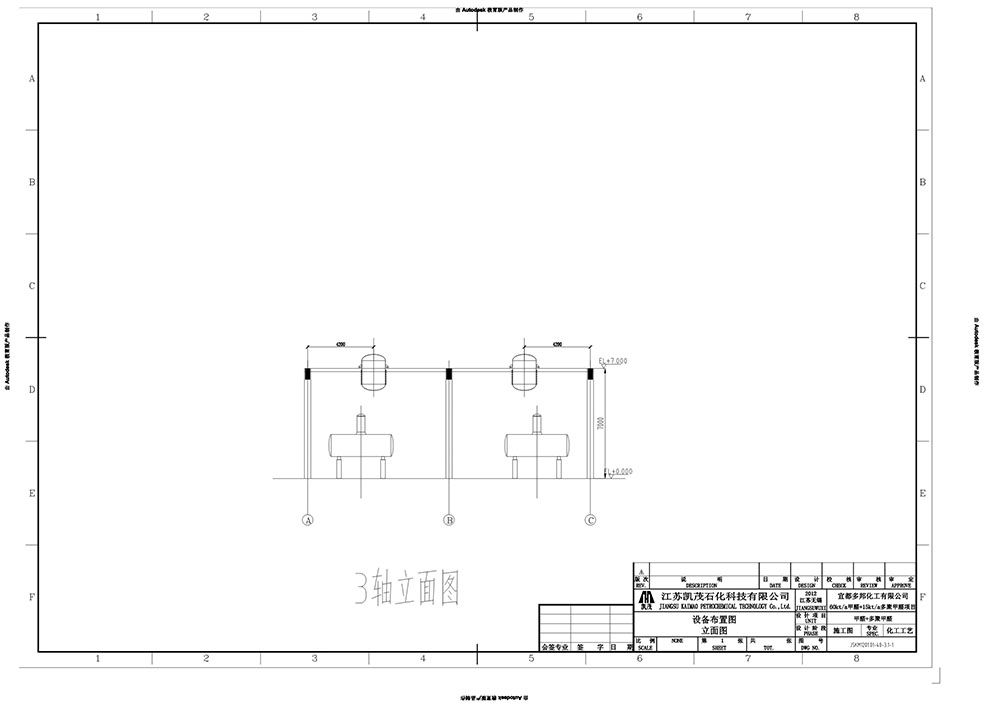

(2).Vacuum rake drying

Via distillation kettle, it is put into rake dryer for further dewatered, finally getting paraformaldehyde. The product is unloaded from the discharging port of dryer, cooled, smashed and packed for storage.

(3).Off-gas treatment

The off gas discharged from the Rake dryer includes steam and formaldehyde steam, pumped from the vacuum pump, circularly absorbed via drying absorber. When the absorption liquid of dilute formaldehyde solution reaches to the certain concentration, it will be sent to dilute formaldehyde storage tank. The none-condensed gas discharged from the drying absorber, via washed, will be pumped by the vacuum pump, then via gas-liquid separator for separation. The waste gas will be sent to the off gas treatment equipment for concentrated handling and discharging. The solution collected by washing tank and liquid separation tank is discharged into drying absorber, finally put to dilute formaldehyde storage tank. The dilute formaldehyde solution can be used for the production of hexamine, methyal or mixed to 37% formaldehyde for sale.