Two-stage MVR evaporator

Introduction

MVR (Mechanical vapor recompression) evaporation, the operation theory is similar to heat pump, the 2nd stage steam comes from the evaporation system, through the steam compression to increase the pressure and temperature, enthalpy increased, then goes into the heating room of the evaporation system to use as the heat resource.

This kind of evaporation system will use electricity to do the evaporation, Based on the difference of material characters, the energy cost by the compression will be different.

Features

- No or few live steam required.- Low energy cost, low operation cost.

- Could combine with crystallizer to form the continue and crystallization system.

- The condenser is not needed or just need a small one.

Application Range

High salinity water treatment, desalination, ZLD system, jam, juice, concentration.

System components

Evaporator, separator, condenser, vacuum and discharging system, delivery pump, PLC, electrical appliance and instruments, valves, pipelines etc.

MVR evaporator technology

MVR applied mechanical vapor recompression unit for compressing the secondary vapor so that recycle the secondary vapor completely in a closed-loop circulation system. As a result of the vapor compressor, temperature and pressure of the secondary vapor raised, the heat efficiency boosted. The effectiveness of live steam is equal to 30 effects of multiple effect evaporator. Thus reducing the demand for external live vapor and cooling resources, energy conservation and less pollution attained.

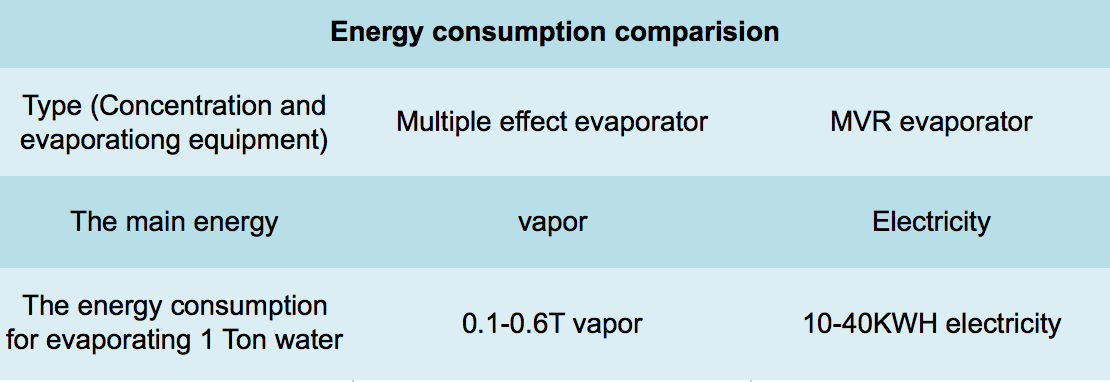

Energy consumption

Related photos