2. The diamond blades ensure high quality cutting, that is minimum variant and loss of cutting material. It can be 45 degree cutting both from top and bottom

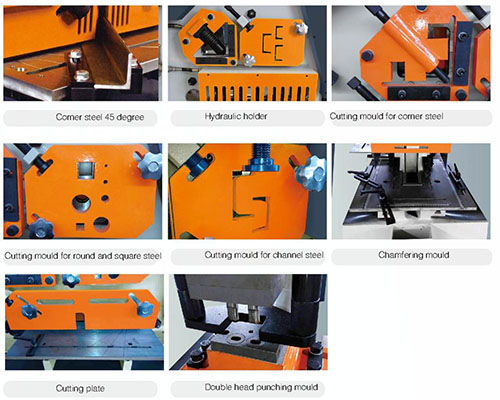

3. Cutting position of round steel and square steel has several different size hole, adjustable fixing device is convenient for cutting different sizes steel

4. Optional blades

5. Adopt large nut and square stop plate to ensure precision

6. Adopt potection guarding to guarantee operation safety

Advantage of the machine

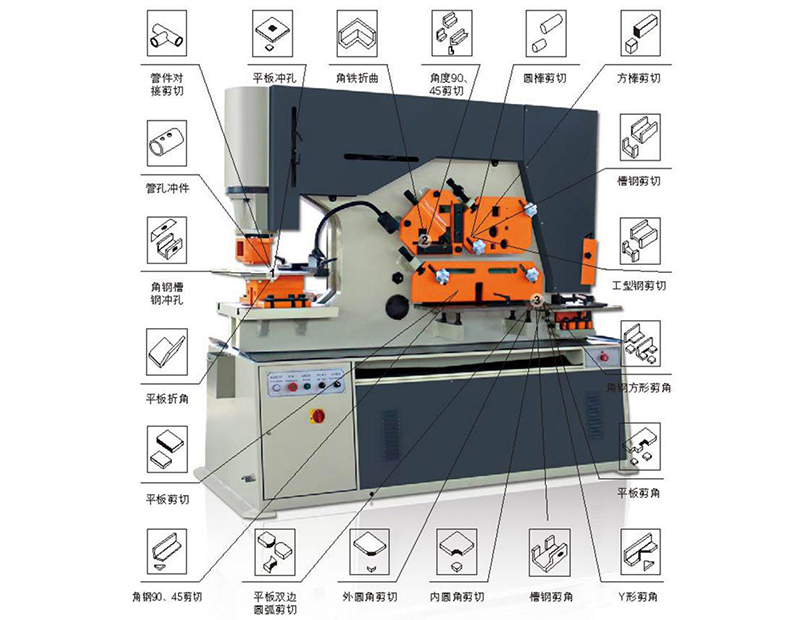

1.Q35YL Series Hydraulic Iron worker,Totally European design,the machine are strong and easy to use machines which are able to can cut and punch all kinds of materials such as plate,square bar,round bar,channel and so on.

2.ADH industrial hydraulic iron workers have been designed and built to the highest quality standards in the industry.This profitable machine will serve any grueling fabrication shop for decades to come.

3.The machine by the European union CE certification and ISO quality system certification.

4.Adopt hydraulic drive,this series machine is suitable for the plastic material of blanking,drawing and pressing process.Such as sheet metal blanking, stretching, fine blanking,the cold extrusion of metal parts

5.Hydraulic transmission is the latest product of the multi-function joint punching and shearing machine,shearing punching,die cut flat steel,square steel,round steel,angle steel,channel steel,I-beam carried,and equipped with shear blOck feeding devices.

Attention

1.Punching and notching work should not be performed at the same time.

2.Keep all edges of blades sharp.

3.To ensure safe punching and cutting work the hold-down unit should be adjusted according to any thickness of material within the cutting capacity of the machine.

Optional mold

| Model |

Punching Pressure (T) |

Max.cutting thickness of steel plates (mm) |

Plate strength (N/mm²) |

Angle of Shear (°) |

A trip size (T*W)(mm) |

Slider trip (mm) |

Trips frequency (times/min) |

Throat depth (mm) |

Punch depth (mm) |

Max.Punching diameter (mm) |

Main Motor Powe (KW) |

Overall dimensions (L*W*H)(mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q35Y-12 | 35 | 12 | ≤450 | 7° | 300*12 | 35 | 10-18 | 115 | 12 | 25 | 4 | 950*550*1800 |

| Q35Y-16 | 55 | 16 | ≤450 | 7° | 16*250 8*400 | 80 | 9-25 | 300 | 16 | 25 | 4 | 1640*730*1770 |

| Q35Y-20 | 75 | 20 | ≤450 | 8° | 20*330*10*480 | 80 | 10-28 | 355 | 20 | 30 | 5.5 | 1860*800*1900 |

| Q35Y-25 | 110 | 25 | ≤450 | 8° | 25*330*16*600 | 80 | 9-18 | 400 | 25 | 35 | 7.5 | 2355*960*2090 |

| Q35Y-30 | 140 | 30 | ≤450 | 8° | 30*335*20*600 | 80 | 7-16 | 600 | 26 | 38 | 11 | 2680*1040*2300 |

| Profile | Round Bar | Square Bar | Equal Angle | T-Bar | Joist | Channel | |||

|---|---|---|---|---|---|---|---|---|---|

| 90°Shearing | 45°Shearing | 90°Shearing | 45°Shearing | ||||||

| Section |

|

|

|

|

|

|

|||

| Q35Y-12 | 35 | 30*30 | 100*100*8 | 10# | 10# | ||||

| Q35Y-16 | 45 | 40*40 | 125*125*12 | 70*70*8 | 120*120*12 | 60*60*8 | 126*74*5 | 126*53*5.5 | |

| Q35Y-20 | 50 | 50*50 | 140*140*12 | 70*70*10 | 140*140*12 | 70*70*10 | 160*86*6 | 160*60*6.5 | |

| Q35Y-25 | 60 | 50*50 | 160*160*14 | 80*80*7 | 160*160*14 | 80*80*10 | 200*102*9 | 200*75*9 | |

| Q35Y-30 | 65 | 55*55 | 180*180*16 | 80*80*10 | 180*180*16 | 80*80*10 | 280*124*10.5 | 280*86*11.5 | |