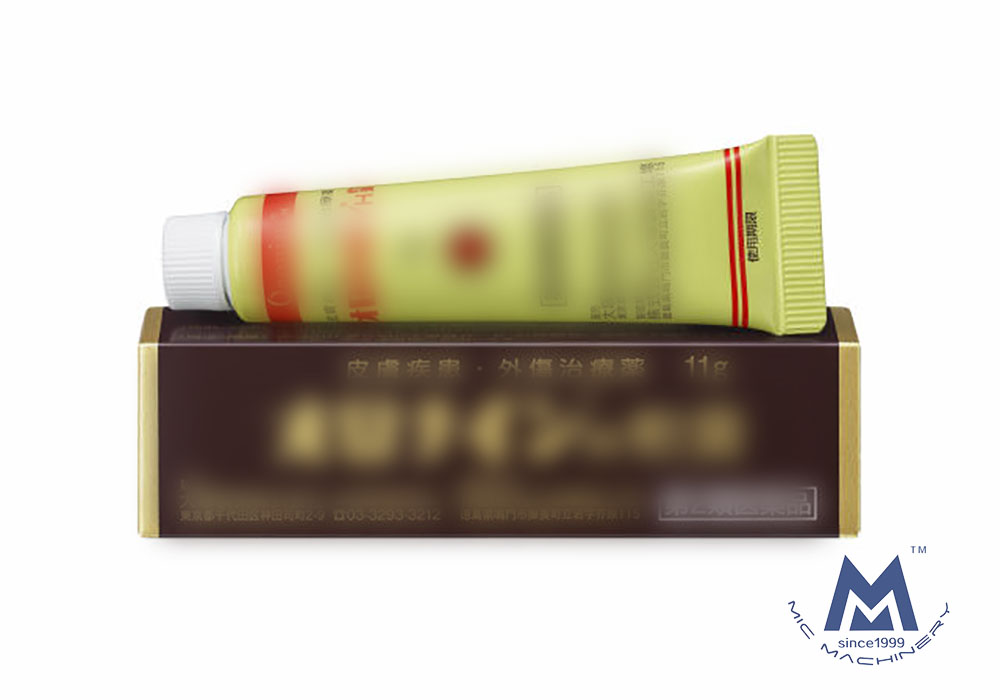

cosmetic, pharmacy, foodstuff, bond industries and other similar products.

The machine main function is :

1. Automatic loading tube

2. Automatic filling material , filling system can customize according to different material

3. Automatic sealing , sealing method can customize , different thickness tube and different material tube can customize different sealing method , like Swiss heating gun sealing or inside and outside double heating

4. High efficient and high precise

5. Easy to operate and flexible

6. Stainless steel machine body , next and beautiful

Its working principle is: The tubes in tube chamber vertically enter into the first-station tube holder one by one, and transferred together with the rotating turn plate to the second-station for I. Marking detection. The third station is for tube locating and reversal inspection (nitrogen jet tubes cleaning is optional). The material filling is in the fourth station and then come to the sealing(and tail bending) station for heating (PE tube) folding (metal tube), tail sealing (PE), clamping (metal), batch number printing, cooling, cutting and at last finished products discharging. Every tube should go through the whole procedure and then finished after filling and sealing. The main structure of the machine is consisted of main transmission, feeding, rotation, tail sealing, filling and electricity control system.

This machine is a 1 filling head filling machine with a heating gun. It has total 12 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste etc., are all applicable.

About the machine use problem, after the sales,

we will take video for:

1. how to connect the power

2. how to operate the machine

3. how to maintain the machine and how often to do it

4. how to adjust machine to different bottle or material.

Thank you for the reading this article,

you can also check for:

→ Our machine application ←

→ Our machine lately export news ←

|

Voltage |

110V/220V/380V optional |

|

Main Motor Power |

4.5kw |

|

Air Source |

0.6-0.8 Mpa |

|

Air Consumption |

0.6 m^3/min |

|

Capacity |

30-60 tubes/min |

|

Filling Accuracy |

+/-1% |

|

Size |

1950*800*1850mm |

|

Weight |

850kg |

| Parts | Brand |

|

touch Screen |

Siemens / Schneider (Optional) |

|

Main Motor |

Tai Wan CBG |

|

PLC |

Siemens / Schneider(Optional) |

|

Stepping Motor |

East Japan |

|

Stepping Drive |

East Japan |

|

Sensor |

Germany Sick |

|

Approach Switch |

Germany Sick |

|

Intermediate Relay |

Schneider |

|

electromagnetic Valve |

Germany SMC |

|

Encoder |

Omron |

|

Mixing Motor (Optional) |

JSCC |

|

Air Cylinder |

SMC |

|

Bearing |

FAGINA |

|

Button |

Schneider |

|

Air Switch |

Schneider |

|

Power Switch |

Schneider |

|

Temperature Control |

Schneide |