Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

-

Plastic syringe filling machine(MIC-SGJ-1 syringe filling and plugging production line)

Filling and packaging of various syringes, boosters, injection tubes and the like in the fields of medicine, chemistry, biology and the like. 1. Prefilled syringe filling machines Accurate filling, controlling bubble during plugging. Automatic operation with monitoring

0 -

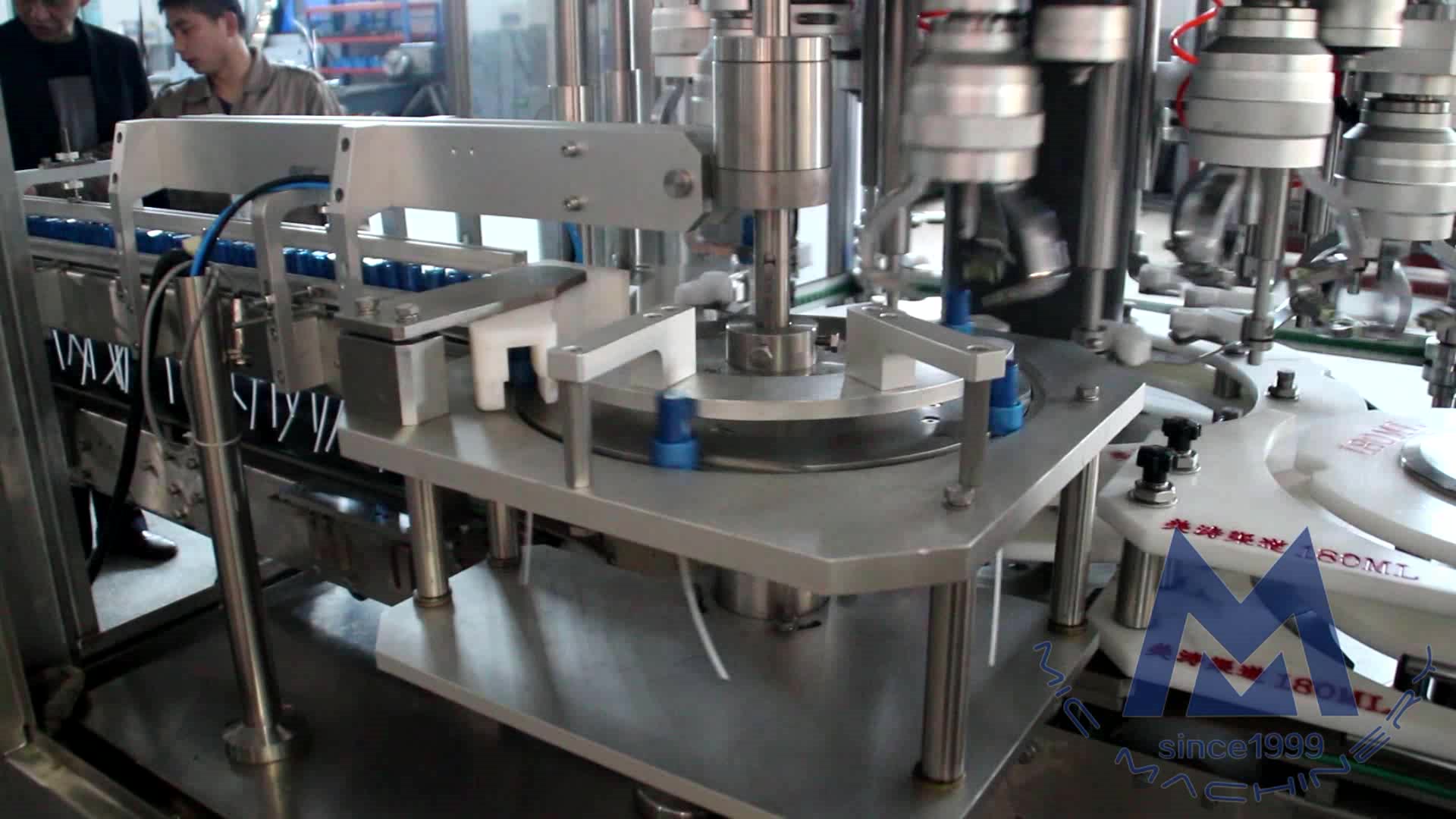

Quotation for trigger capping machine (Rotated) speed 4000-5000 piece per hour

Heads 8 Piece Machine Size 2000*1600*2600mm Weight 4000kgs Cap Size Diameter 30mm, Length 250mm Speed

161

- Contacter: lewis

- Tel: 0086-13083991987

- Fax:

- Email: market@micmachinery.com

-

Company Address:

No.28 Xin Hu Road, Wu Jin Area Xue Yan Town, ChangZhou City, Jiang Su

Plastic syringe filling machine(MIC-SGJ-1 syringe filling and plugging production line)

Filling and packaging of various syringes, boosters, injection tubes and the like in the fields of medicine, chemistry, biology and the like.

1. Prefilled syringe filling machines Accurate filling, controlling bubble during plugging. Automatic operation with monitoring all the way. Beside normal liquid, also suitable for filling transparent viscous liquid like ester acid.

2. Prefilled syringe filling machine included 2sets of servo motorsfor accurate filling, plugging reliability and accurate row by row moving during filling operation.

3. Prefilled syringe filling machines S/S rotating pump. Filling volume set-up and accuracy tuning are operated on touch-screen without any tool.

4. Prefilled syringe filling machines SIEMENS color touch screen. Real time monitoring and display of each operating status, vacuum pressure, nitrogen pressure, C/A pressure, fault alarm with position indication, fault indication and record. Multi-languages display.

6. Prefilled syringe filling machines Process parameters can be timely printed, stored and retrievable.

silicon rubber. Machine is coated with SUS 304 and 6061 oxidated aluminum alloy.

1. how to connect the power

3. how to maintain the machine and how often to do it

→ Our machine application ←

Plastic syringe filling machine(MIC-SGJ-1 syringe filling and plugging production line)

Filling and packaging of various syringes, boosters, injection tubes and the like in the fields of medicine, chemistry, biology and the like.

1. Prefilled syringe filling machines Accurate filling, controlling bubble during plugging. Automatic operation with monitoring all the way. Beside normal liquid, also suitable for filling transparent viscous liquid like ester acid.

2. Prefilled syringe filling machine included 2sets of servo motorsfor accurate filling, plugging reliability and accurate row by row moving during filling operation.

3. Prefilled syringe filling machines S/S rotating pump. Filling volume set-up and accuracy tuning are operated on touch-screen without any tool.

4. Prefilled syringe filling machines SIEMENS color touch screen. Real time monitoring and display of each operating status, vacuum pressure, nitrogen pressure, C/A pressure, fault alarm with position indication, fault indication and record. Multi-languages display.

6. Prefilled syringe filling machines Process parameters can be timely printed, stored and retrievable.

silicon rubber. Machine is coated with SUS 304 and 6061 oxidated aluminum alloy.

1. how to connect the power

3. how to maintain the machine and how often to do it

→ Our machine application ←

Quotation for trigger capping machine (Rotated) speed 4000-5000 piece per hour

Heads

8 Piece

Machine Size

2000*1600*2600mm

Weight

4000kgs

Cap Size

Diameter 30mm, Length 250mm

Speed

80 Piece above per min

Torque Control

+/-0.3Nm

Capping Rate

≥98% (error from centre of bottle mould<1mm, height error<1mm)

Voltage

AC 380V 50Hz

Machine Power

4Kw

Need Air Supply

0.6Mpa clean air

Quotation for trigger capping machine (Rotated) speed 4000-5000 piece per hour

Heads

8 Piece

Machine Size

2000*1600*2600mm

Weight

4000kgs

Cap Size

Diameter 30mm, Length 250mm

Speed

80 Piece above per min

Torque Control

+/-0.3Nm

Capping Rate

≥98% (error from centre of bottle mould<1mm, height error<1mm)

Voltage

AC 380V 50Hz

Machine Power

4Kw

Need Air Supply

0.6Mpa clean air