Multifunctional Evaporator Process

Performance

Overview

Specification of Product

Consumption Quota of Feedstock, Auxiliaries & Power

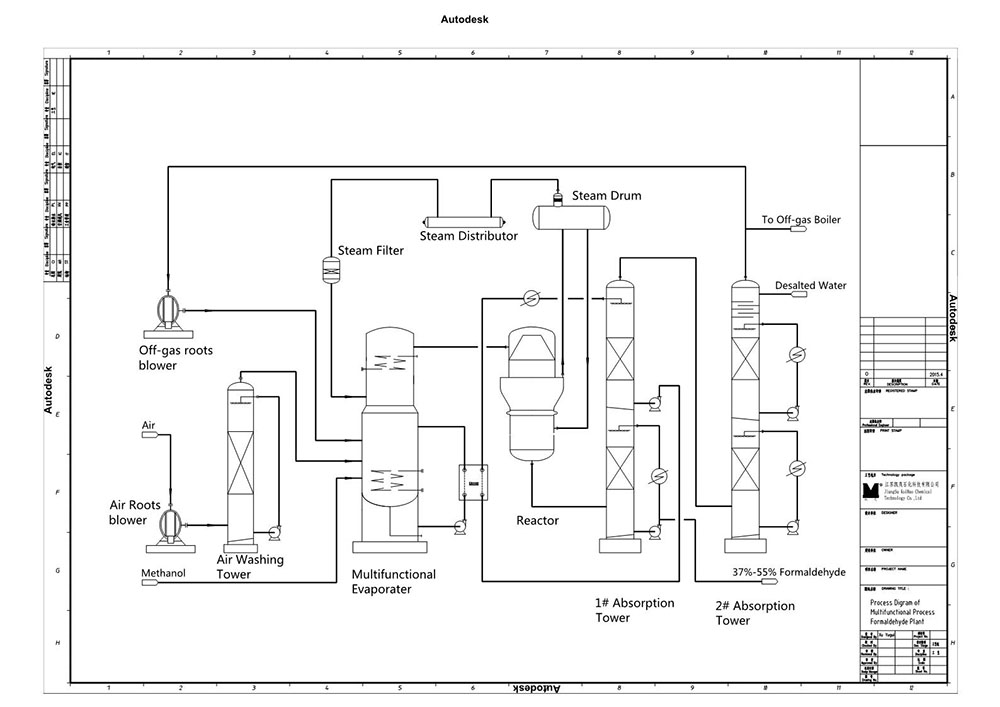

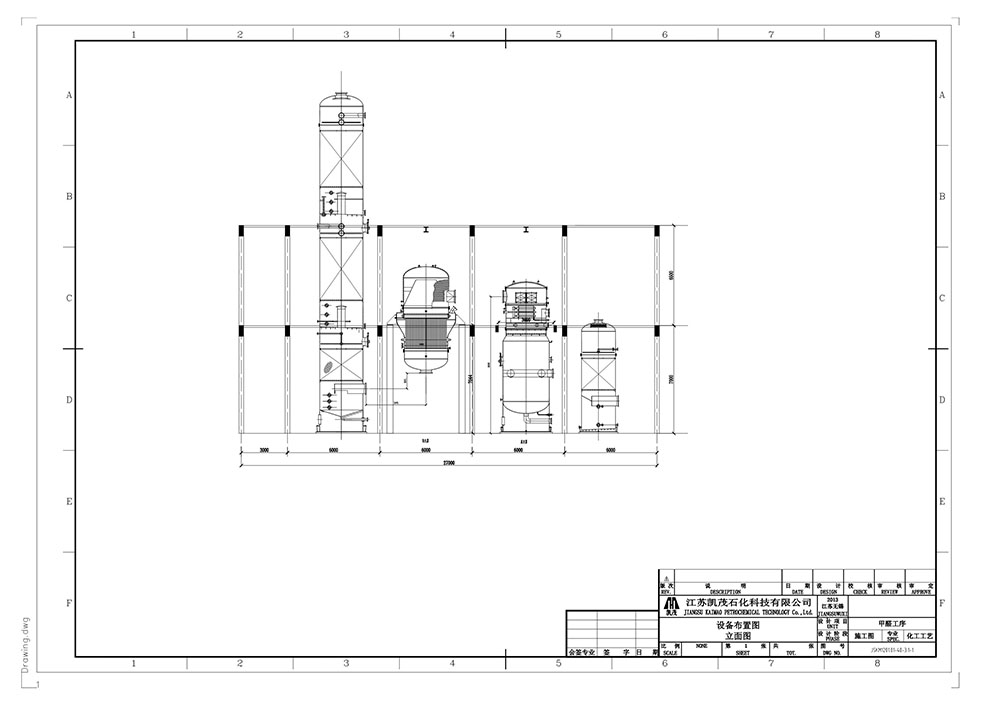

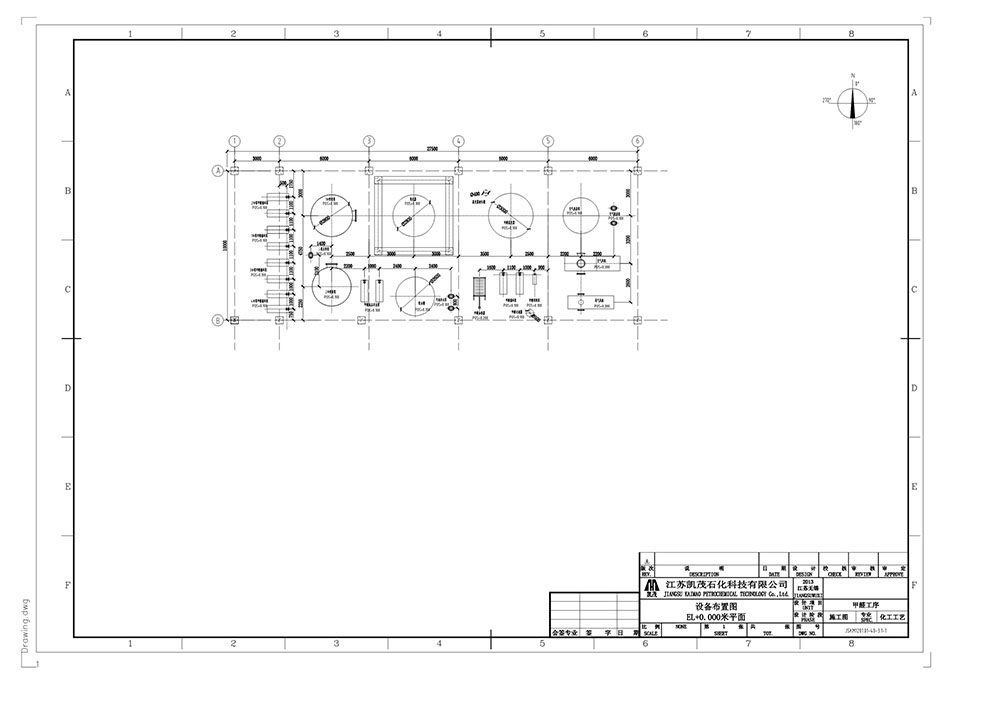

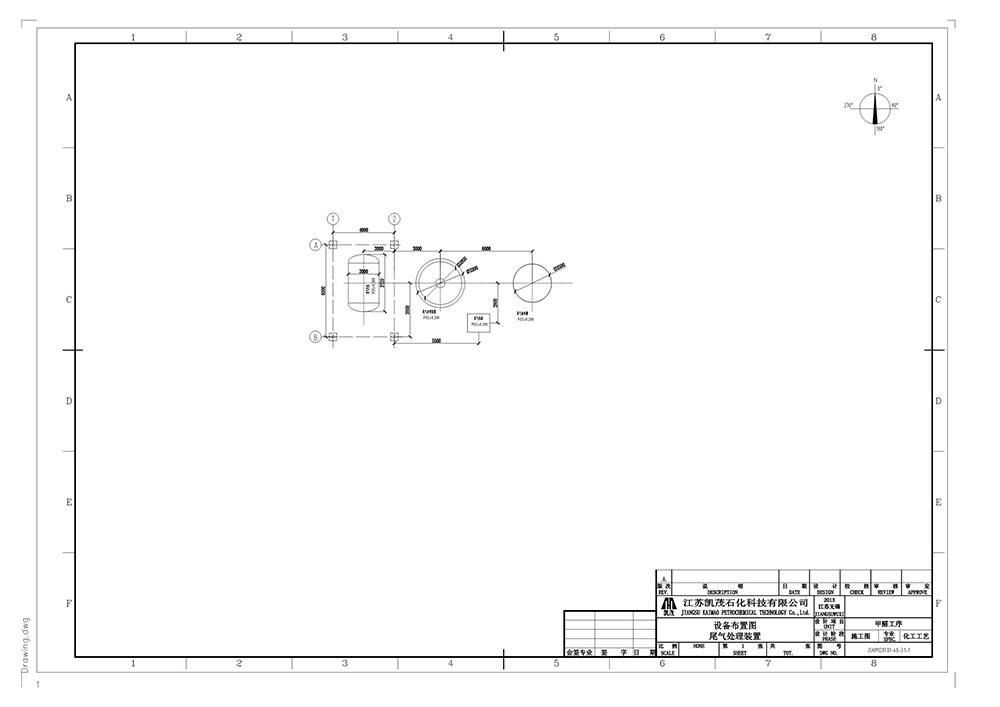

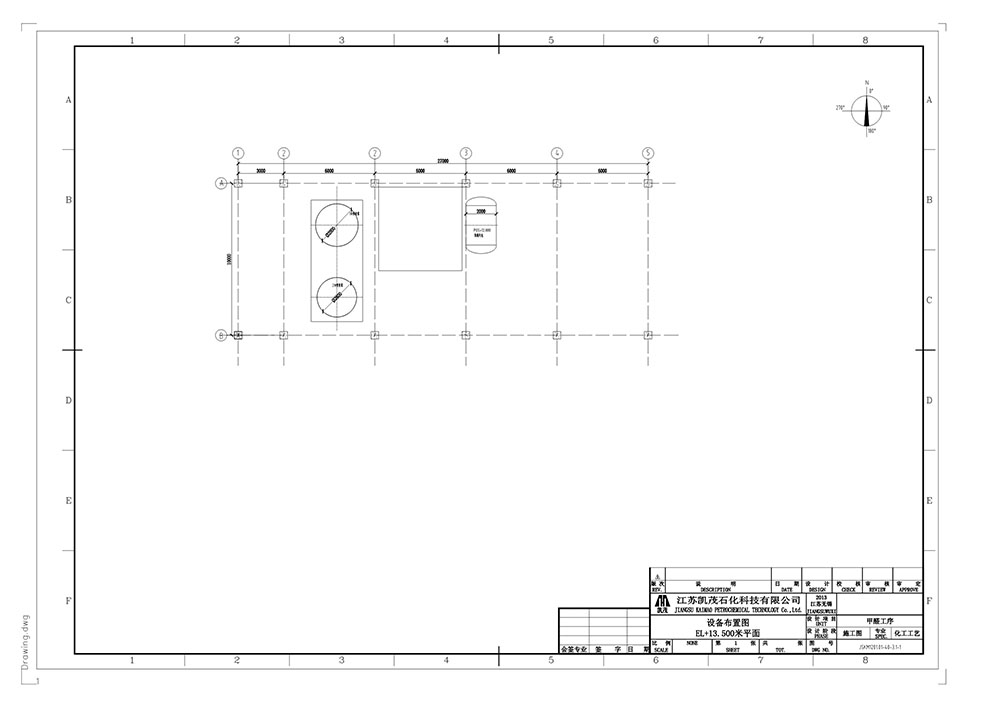

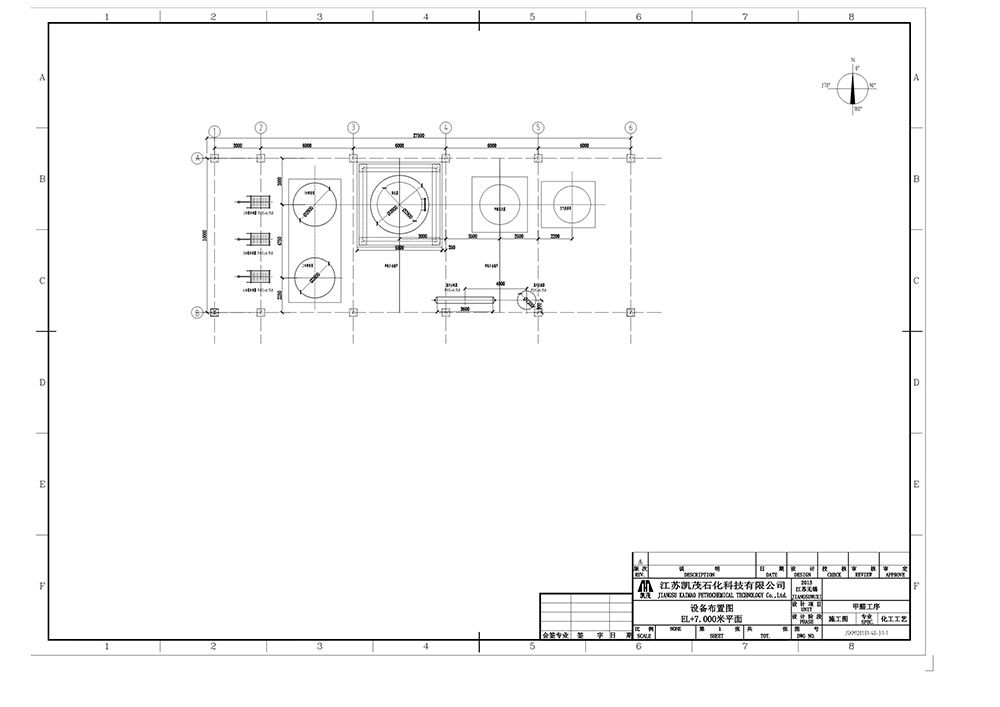

Process Digram&Layout Drawing

References

| S/N | Component | Index |

|---|---|---|

| 1 | Formaldehyde | 37-55% |

| 2 | Methanol | ≤1 wt. % |

| 3 | Formic Acid | ≤0.01 g/100 ml |

| 4 | Chloride | ≤0.0025 g/100 ml |

| 5 | Ashes | ≤0.01 g/100 ml |

Consumption Quota of Feedstock, Auxiliaries & Power

| S/N | Particular | Index | Remark |

|---|---|---|---|

| 一 | Feedstock & Auxiliaries | ||

| 1 | Methanol(99.5%) | 0.445 ton for per ton of 37% formalin product | Expectation:442 |

| 2 | Catalyst ( Silver ) | As-per the Capacity | Single production line |

| 二 | Civil Utilities | ||

| 1 | Circulating Cooling Water | 40 ton for per ton of 37% formalin product | |

| 2 | Desalted Water | As-per the process | |

| 3 | Power Electricity (Voltage:415/250V; Frequency 50±0.5Hz) | 28 KWh for per ton of 37% formalin product | With 200kvA transformer |

| 4 | Steam for Startup(0.2Mpa) | 900kg/h | Need 3~4hrs |

| 5 | Export Steam as By-product(0.25MPa) | 150-200kg per ton of 37% formalin product | Without the Off-gas Boiler |

| 6 | Instrumental Air (P=0.5-0.7MPa(G)) | As-per the Capacity |

| Project | Type and parameter | Production line | Finish Date |

|---|---|---|---|

| Qinghai Salt Lake Haihong Chemical Co. LTD. |

20000tpa formaldehyde plant 50000tpa hexamine plant |

1 | 2009.5 |

| Anhui Futai Refined Chemical LLC. | 60000tpa formaldehyde plant | 1 | 2009.12 |

| Chifeng Ruiyang Chemical Co. LTD. | 60000tpa formaldehyde plant | 1 | 2010.3 |

| Xinle Dongyuanjin Chemical Co. LTD. | 60000tpa formaldehyde plant | 1 | 2010.4 |

| Nantong Changqing Chemical Co. LTD. | 50000tpa formaldehyde plant | 1 | 2010.8 |

| Luzhai County Pusheng Chemical LLC. | 60000tpa formaldehyde plant | 1 | 2010.8 |

| Guangxi Donglin Wood Co. LTD. | 50000tpa formaldehyde plant | 1 | 2010.8 |

| Shandong Shengtong Bloc Co. LTD. |

100000tpa formaldehyde plant 50000tpa High concentrations of methylal plant |

2 | 2011.1 |

| Ordos Hongde Chemical LLC. |

80000tpa formaldehyde plant 60000tpa acetaldehyde plant |

2 | 2010.7 |

| Bazhou Hengya Refined Chemical Co. Ltd. |

80000tpa formaldehyde plant 50000tpa methylal plant |

2 | 2011.3 |

| Baisha Southern Ocean industrial Co. Ltd. | 50000tpa formaldehyde plant | 1 | 2011.3 |

| Shandong Dongming Luten Chemical Co. Ltd. | 50000tpa formaldehyde plant | 1 | 2011.4 |

| Shandong Tuobo Haoyuan Chemical Co. Ltd. | 50000tpa formaldehyde plant | 1 | 2011.6 |

| YANCON LUNAN CHEMICAL Fertilizer Plant | 200000tpa High concentrations of formaldehyde plant | 1 | 2011.6 |

| Maoming City Zhongguang Chemical Co. Ltd. |

60000tpa formaldehyde plant 30000tpa High concentrations of methylal plant |

2 | 2011.6 |

| Shanghai Lanxing polyformaldehyde Co. Ltd. | 120000tpa High concentrations of formaldehyde plant | 1 | 2011.9 |

| Chemical Co. Ltd. | 100000 formaldehyde plant | 1 | 2011.10 |

| Hebei Jingtaida Chemical Co. Ltd. | 120000tpa 55%formaldehyde plant | 1 | 2013.03 |

| Changzhou Qiaoer Plastic Co. Ltd. | 120000tpa formaldehyde plant | 2 | 2012.3 |

| Shandong Shangdian Chemical Co. Ltd. | Add copper wire mesh to formaldehyde reactor and heat exchanger | 1 | 2012.02 |

| Shandong Shang County Ningfeng Chemical Co. Ltd. | 50000tpa formaldehyde plant | 1 | 2012.05 |

| Shandong Shang County Ningfeng Chemical Co. Ltd. | 80000tpa formaldehyde plant | 1 | 2013.02 |

| Hebei Yuhang Chemical Co. Ltd. | 120000tpa 55%formaldehyde plant | 1 | 2012.05 |

| Hebei Yuhang Chemical Co. Ltd. | 60000tpa 50%formaldehyde plant | 1 | 2012.05 |

| Wenan County Pacific Chemical Co. Ltd. |

80000tpa formaldehyde plant 60000tpa methylal plant |

2 | 2012.07 |

| Inner Mongolia Linfeng Chemical Co. Ltd. | 200000tpa formaldehyde plant | 1 | 2012.09 |

| Yidu City Duobang Chemical Co. Ltd. | 50000tpa formaldehyde plant | 1 | 2012.10 |

| Xianyang Hongyuan petrochemical industrial Co. Ltd. | 60000tpa formaldehyde plant and 60000tpa High concentrations of methylal plant | 2 | 2013.02 |

| Shandong Zibo Jingchang Combustion-supporting Material Technology Co. Ltd. | 100000tpa High concentrations of formaldehyde plant | 1 | 2013.03 |

| Tangshan Chenghong Industrial Co. Ltd. | 50000tpa formaldehyde plant | 1 | 2013.04 |

|

Leshan Fuhua Tongda pesticide Technology Co. Ltd. Leshan Hongya Chemical Co. Ltd. |

240000tpa formaldehyde plant and 60000tpa paraformaldehyde plant | 4 | 2013.4 |

| Jilin Sengong Chemical Co. Ltd. | 50000tpa 55%formaldehyde plant and 30000tpa High concentrations of methylal plant | 2 | 2013.12 |

| Fujian Longyan Lianrun Chemical Co. Ltd. | 60000tpa High concentrations offormaldehyde plant | 2 | 2014.04 |

| Gaungxi Hongda Bio-energy Technology Co. Ltd. | 120000tpa formaldehyde plant | 1 | 2013.12 |

| Zibo Qixing Chemical Technology Co. Ltd. | 50000tpa formaldehyde plant and 30000tpa methylal plant | 2 | 2014.06 |

| Hebei Donghuan Jiheng Chemical Co. Ltd. | 50000tpa 55% formaldehyde plant | 1 | 2014.04 |

| India WINDSON Co. | 40000tpa formaldehyde plant | 1 | 2014.06 |

| Shandong Yiyuan Petrochemical co., LTD. | 50000tpa 55% High concentrations of formaldehyde plant | 1 | 2014.04 |

| Xinjiang Hengyang Chemical Co. Ltd. | 100000tpa formaldehyde plant and 50000tpa methylal plant | 2 | 2014.06 |

| Jiangxi Gaoxin Technology Co. Ltd. | 50000tpa formaldehyde plant | 1 | 2014.12 |

| Hebei Aerospace Chemical Co. Ltd. | 120000tpa formaldehyde plant | 1 | 2014.12 |

| Chengdu Liantai Chemical Co. Ltd. | 80000tpa formaldehyde plant | 1 | 2014.06 |

| Chongqing Deya Chemical Co. Ltd. | 50000tpa formaldehyde plant | 1 | 2014.12 |

| Shandong Hongda Biological technology Co., Ltd. | 120000tpa formaldehyde plant | 1 | 2014.12 |

Multi-functional evaporator process is the newest silver contact formaldehyde production process, independently researched and developed by Kaimao team. It is Kaimao’s patented technology, which has been applied with several national patents. Since 2010, dozens of these plants has been built, creating good technological and economical benefits.

The advantage is the stable process, high steam production, less land coverage and big capacity. The capacity is 60TPD-400TPD and the concentration can be flexibly adjusted between 37%~ 55%.

Air, after filtering, washing and heating, comes into the multi-functional evaporator. Steam, after filtration, comes into evaporator. The circulation off-gas from the top of 2# absorber, after heating, comes into evaporator. The filtered methanol liquid comes into methanol evaporator. In the methanol evaporator, it can go through complex processes, such as bubbling, heating, evaporation, mixing, separating and heating, thus a large number of steam be can saved.

Quaternary gas comes into methanol reactor, having redox reaction and gets formaldehyde gas. The formaldehyde gas from the reactor also includes steam, nitrogen, oxygen and hydrogen, and it needs the next absorption process, getting formaldehyde solution.

The process adopts 2 specially designed absorption towers. 37%-55% formaldehyde solution can be produced by these absorbers. The absorption technology is the Kaimao’s patent. This process is highly recommended by us for the clients who prefer high concentration formaldehyde.

PDF

The advantage is the stable process, high steam production, less land coverage and big capacity. The capacity is 60TPD-400TPD and the concentration can be flexibly adjusted between 37%~ 55%.

Air, after filtering, washing and heating, comes into the multi-functional evaporator. Steam, after filtration, comes into evaporator. The circulation off-gas from the top of 2# absorber, after heating, comes into evaporator. The filtered methanol liquid comes into methanol evaporator. In the methanol evaporator, it can go through complex processes, such as bubbling, heating, evaporation, mixing, separating and heating, thus a large number of steam be can saved.

Quaternary gas comes into methanol reactor, having redox reaction and gets formaldehyde gas. The formaldehyde gas from the reactor also includes steam, nitrogen, oxygen and hydrogen, and it needs the next absorption process, getting formaldehyde solution.

The process adopts 2 specially designed absorption towers. 37%-55% formaldehyde solution can be produced by these absorbers. The absorption technology is the Kaimao’s patent. This process is highly recommended by us for the clients who prefer high concentration formaldehyde.

https://drive.google.com/file/d/1Erbmhmq3pAhVWTaafpRwa4xvyCuI8Ulf/view?usp=sharing

Products

TOP