Industrial Reverse Osmosis Waste Evaporator

RO waste evaporator

MVR mechanical compression and TVR steam compression technology can be added.

Scope of application

Falling film type single, double, triple, fourth, fifth, Sixth, seventh, eighth efficiency, effect evaporator, suitable for evaporation and concentration in milk, starch, glucose, xylose, pharmaceutical, chemical, biological engineering, environmental engineering, waste recycling and other industries, especially suitable for easy scaling easy evaporation strong or heat sensitive materials, including plate, pipe, tube plate combination, can join the MVR, the energy-saving technology of TVR device.

System composition

Kinds of evaporator, all kinds of separator, condenser, hot press pump, vacuum & drainage system, all kinds of effet liquid & feeding & discharge pump, working plate, System composition of electrical and instrument control cabinet, valve and pipeline

Main features

1. Full system design is reasonable and beautiful, stable operation, high efficiency and energy saving, low steam consumption, small pump flow rate, small installed power and low power consumption.

2. Large concentration ratio, falling film evaporation, so that the fluid with larger viscosity is easy to flow and evaporation and the concentration-time is short.

3. Special design can be changed by a simple operation to adapt to the production of different products.

4. Low evaporation temperature, liquid heating concentrated mild, suitable for heat sensitive materials.

5. The equipment can run continuously.

6. Can be added to TVR to improve the utilization of energy.

7. can be added to MVR to improve the utilization of energy.

8. We use condensers which can work at the cooling water temperature as 30 DC or even more.

Industrial Reverse Osmosis Waste Evaporator

Project information: Brine treatment, Stickwater, RO waste, ZLD system, tomato paste/mango juice/orange juice/ Garlic water concentration etc.

Processing capacity: 50kg/hr, 100kg/hr, 300kg/hr, 500kg/hr, 1t/hr, 3 T / hr , 5T / hr , 10 T / hr ,15 T / hr , 20 T/hr, 25T/hr

Installed Projects: Vietnam / China / the Philippines /Indonesia / America/ Hungary ect.

Introduction for the machine

The combination of tube type, plate type and tube plate can be used.MVR mechanical compression and TVR steam compression technology can be added.

Scope of application

Falling film type single, double, triple, fourth, fifth, Sixth, seventh, eighth efficiency, effect evaporator, suitable for evaporation and concentration in milk, starch, glucose, xylose, pharmaceutical, chemical, biological engineering, environmental engineering, waste recycling and other industries, especially suitable for easy scaling easy evaporation strong or heat sensitive materials, including plate, pipe, tube plate combination, can join the MVR, the energy-saving technology of TVR device.

System composition

Kinds of evaporator, all kinds of separator, condenser, hot press pump, vacuum & drainage system, all kinds of effet liquid & feeding & discharge pump, working plate, System composition of electrical and instrument control cabinet, valve and pipeline

Main features

1. Full system design is reasonable and beautiful, stable operation, high efficiency and energy saving, low steam consumption, small pump flow rate, small installed power and low power consumption.

2. Large concentration ratio, falling film evaporation, so that the fluid with larger viscosity is easy to flow and evaporation and the concentration-time is short.

3. Special design can be changed by a simple operation to adapt to the production of different products.

4. Low evaporation temperature, liquid heating concentrated mild, suitable for heat sensitive materials.

5. The equipment can run continuously.

6. Can be added to TVR to improve the utilization of energy.

7. can be added to MVR to improve the utilization of energy.

8. We use condensers which can work at the cooling water temperature as 30 DC or even more.

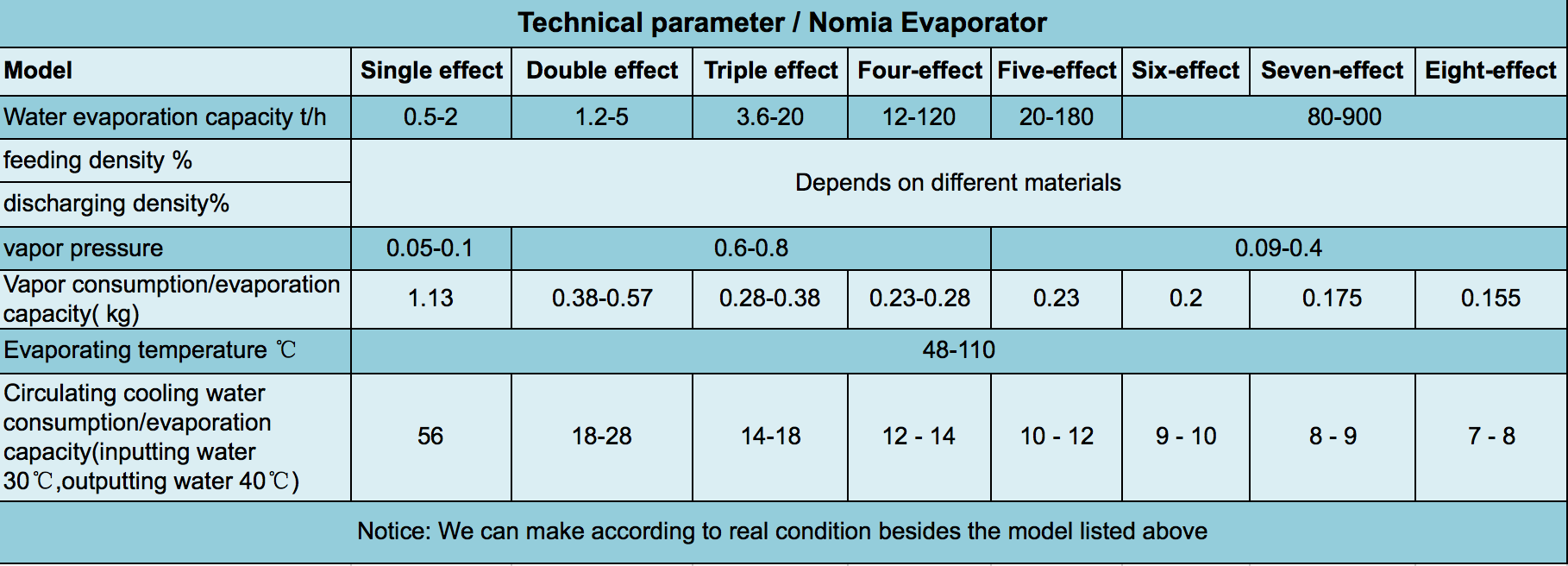

Technical parameter

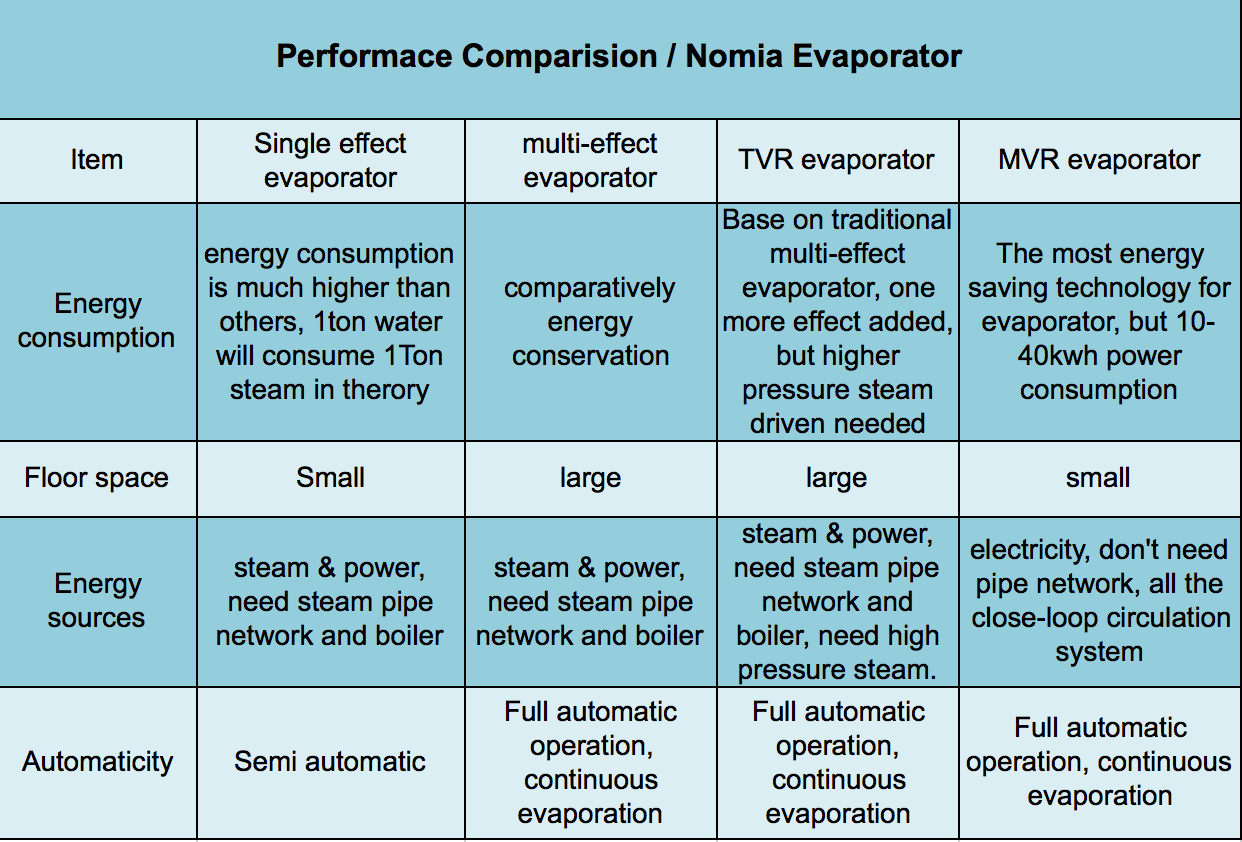

Evaporator performance

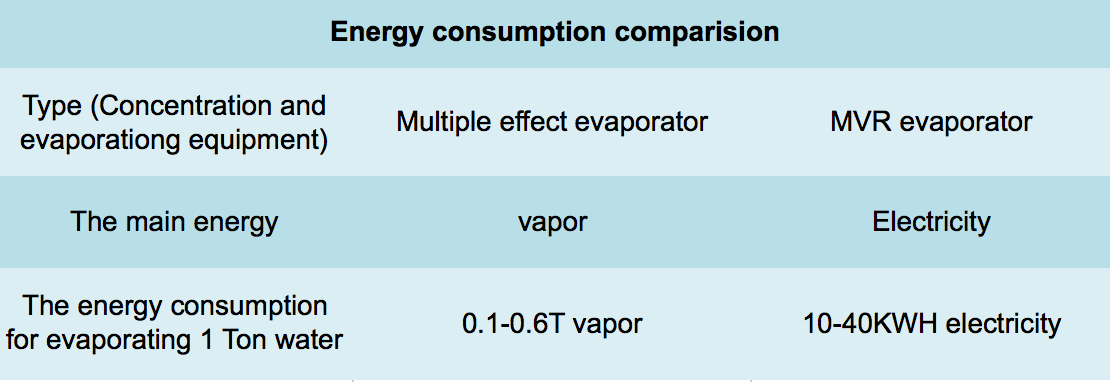

Energy Consumption

Evaporator selection notice

1. compared with electricity and vapor supply cost ahead of time.- 2. MVR invest more than multi-effect evaporator at the early stage, but the cost shall be covered after 300days service.

- 3. The evaporators are custom-built according to feeding liquid and real situation, Please contact us to consult about the suitable evaporator system.

TOP