Gas Phase Process

Performance

Overview

pdf

Specification of Product:

Hexamine As per Chinese National Standard GB/T9015-1998

Appearance: white or light colored crystals without visible impurities.

Calculate in per ton product

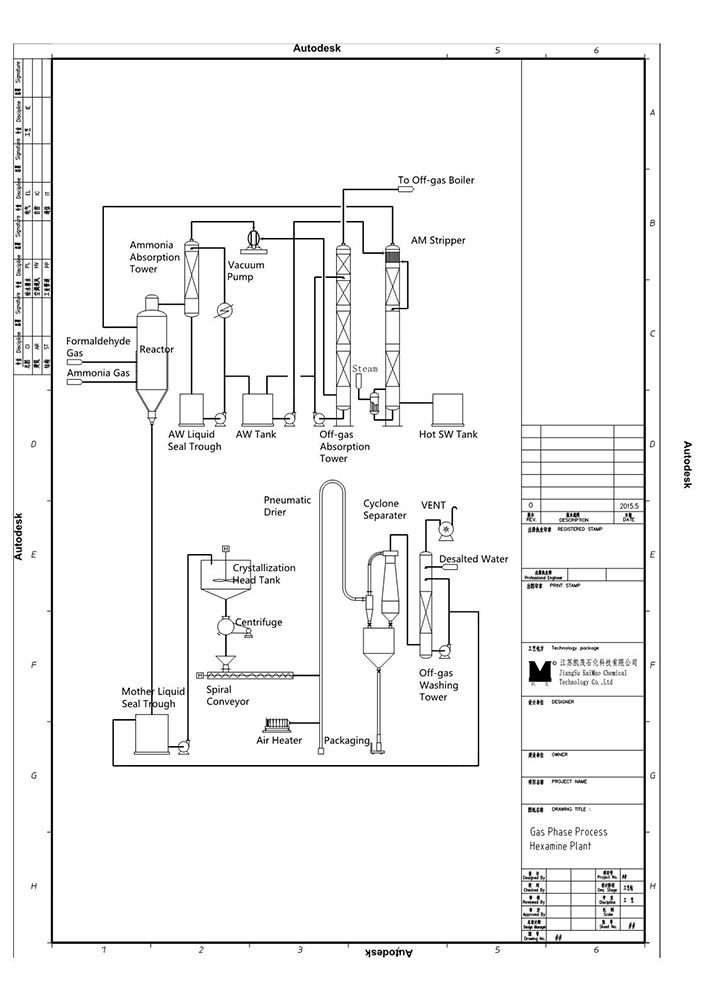

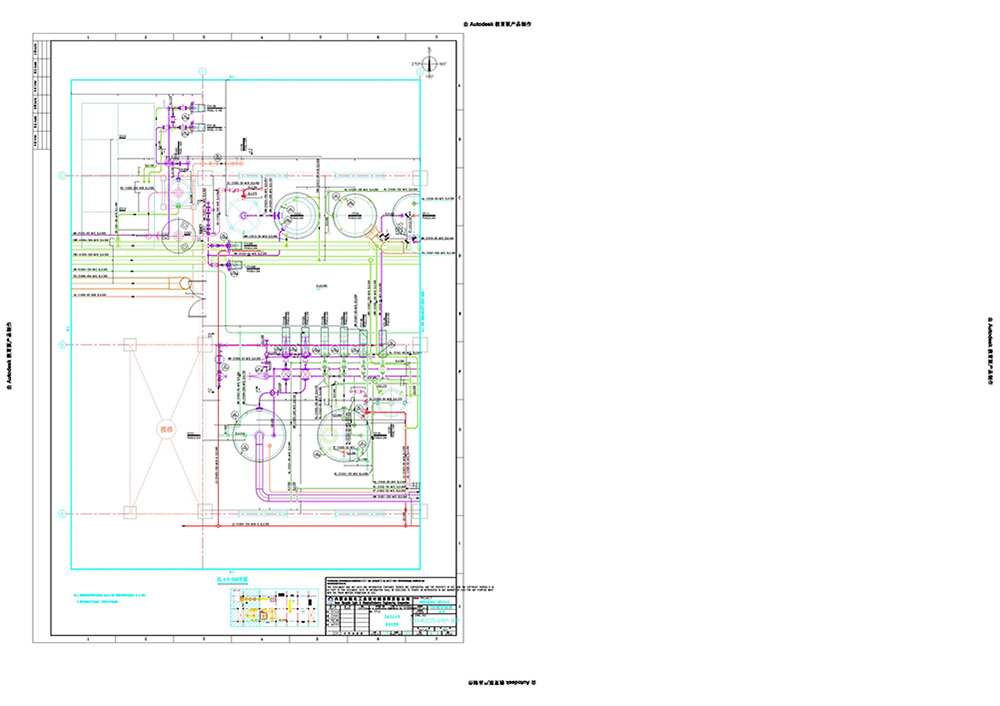

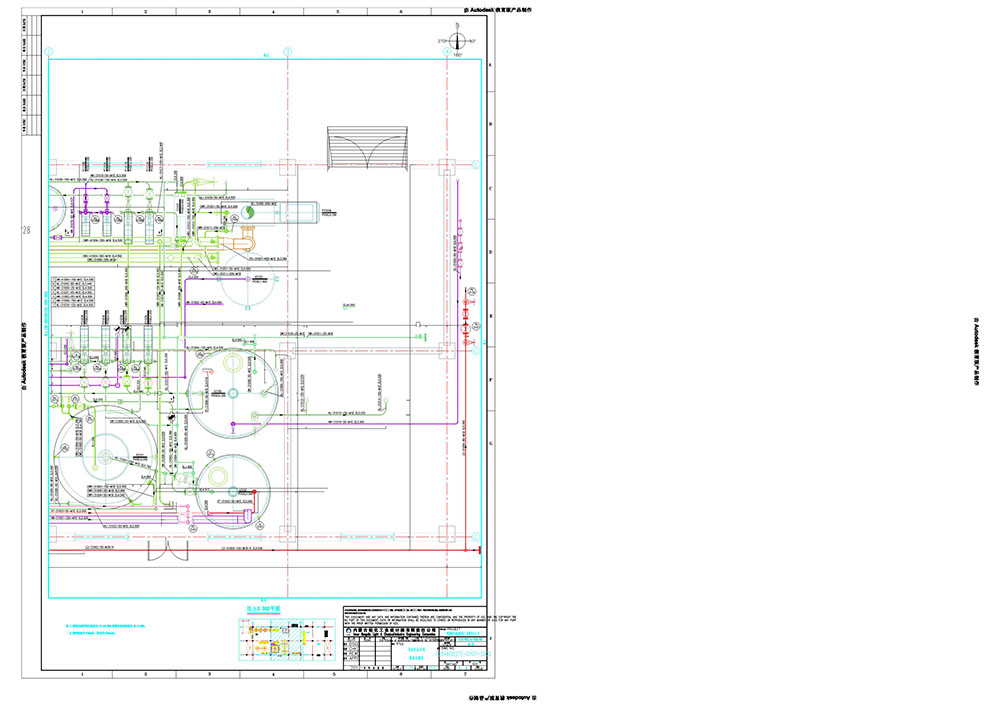

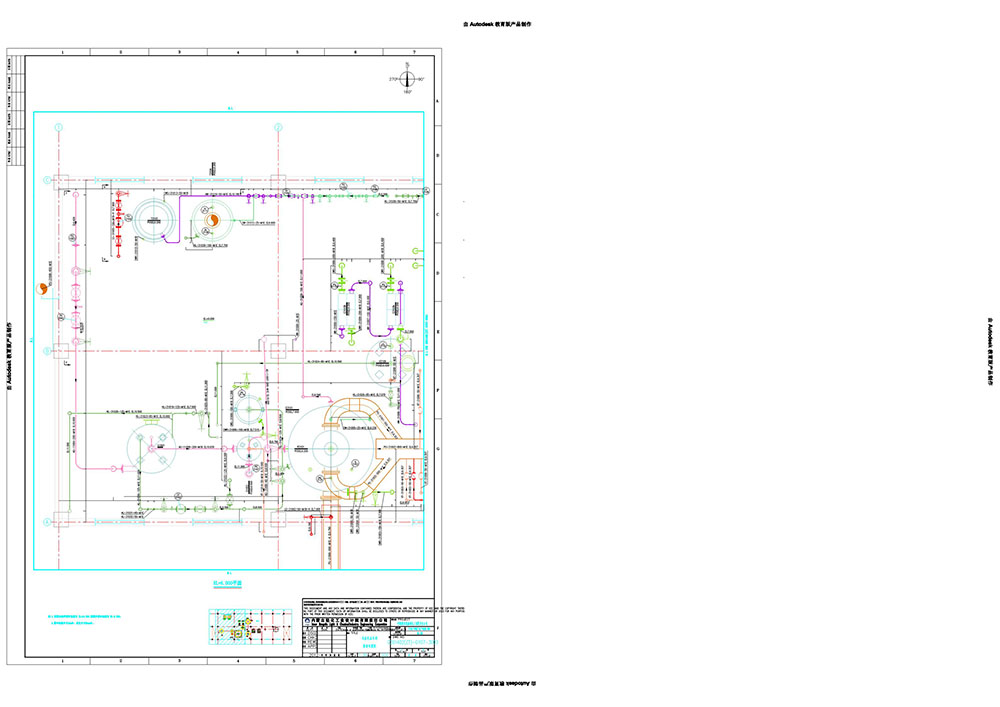

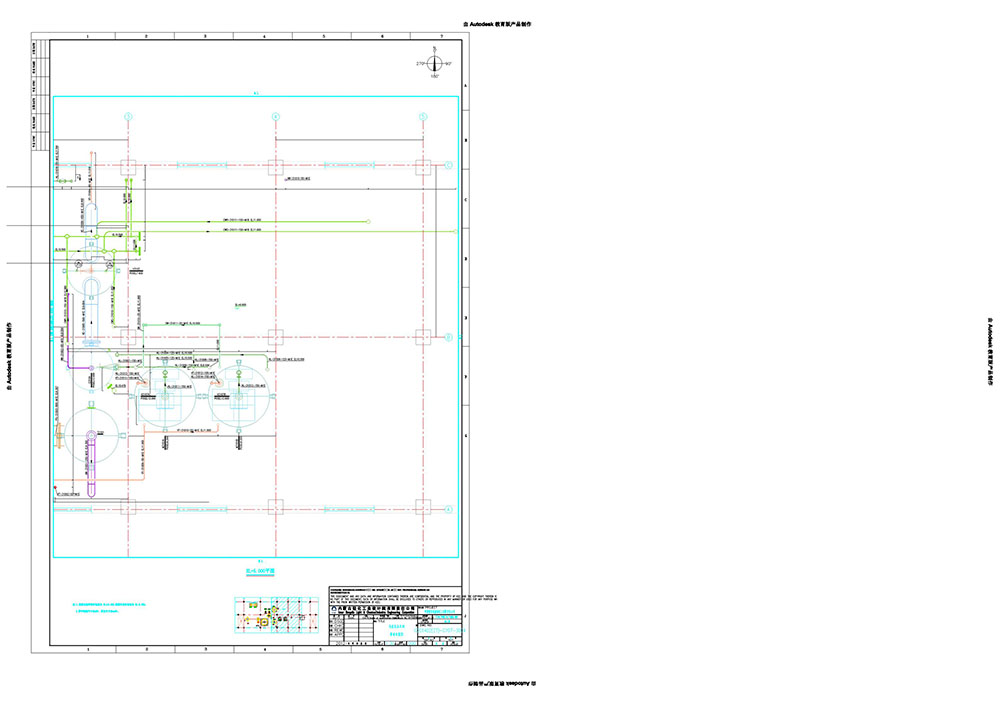

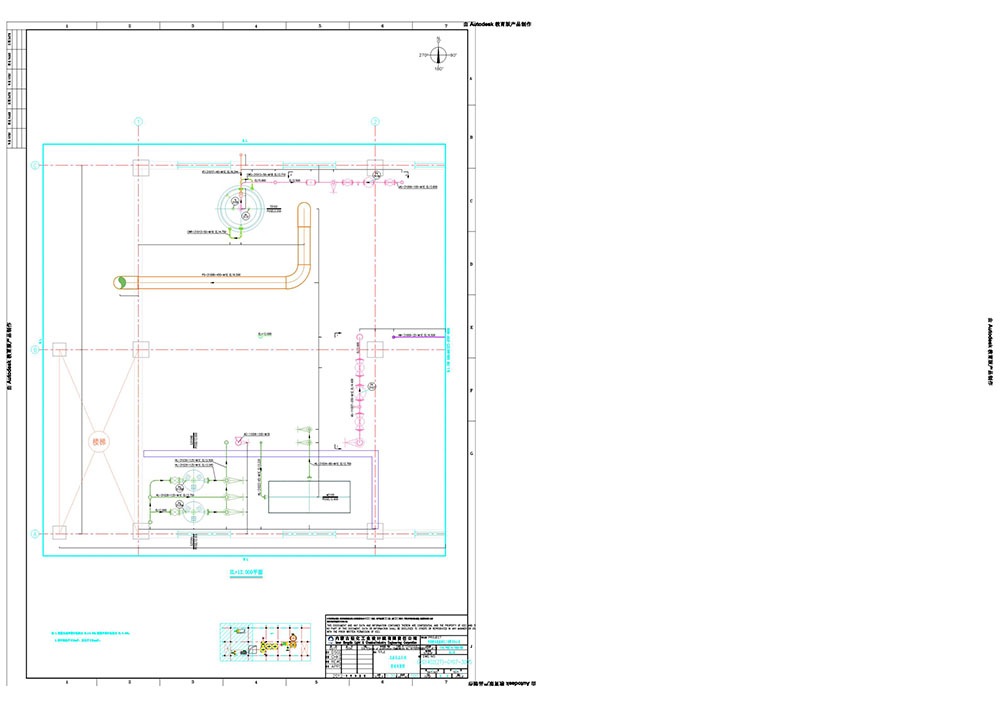

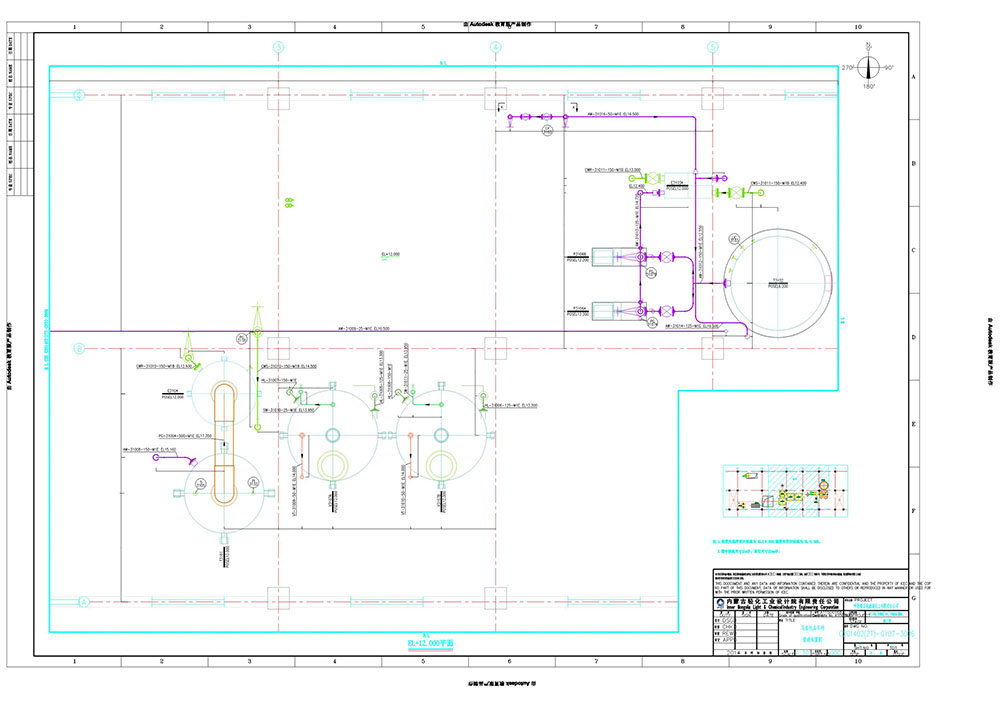

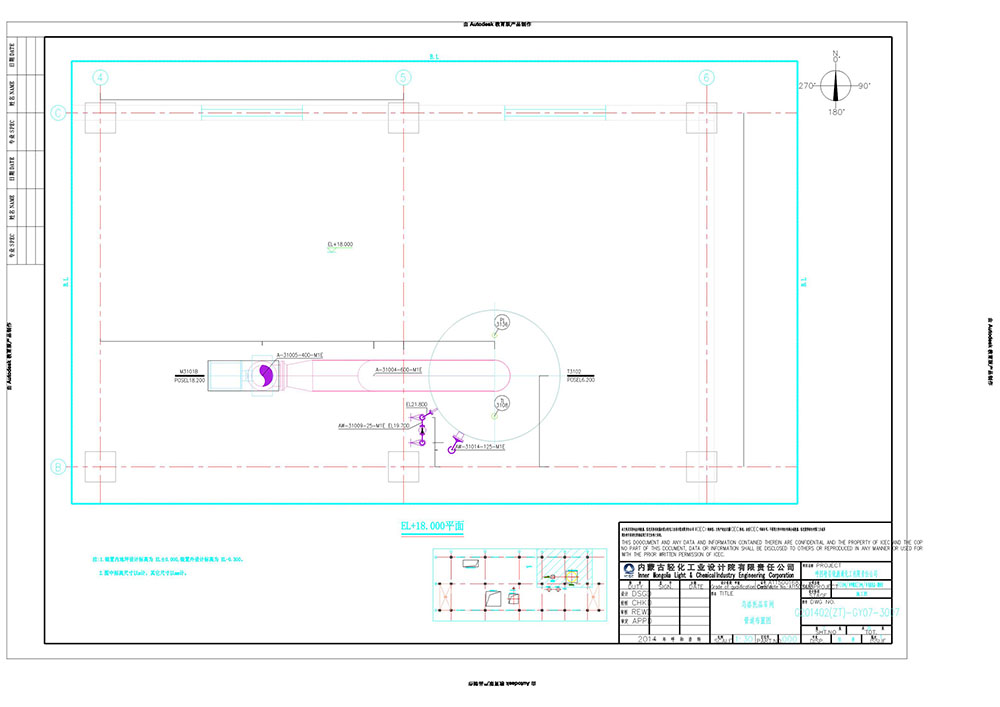

Process Digram&Layout Drawing

References

Hexamine As per Chinese National Standard GB/T9015-1998

Appearance: white or light colored crystals without visible impurities.

| Item | Superior | First Grade | Acceptable |

|---|---|---|---|

| Purity % ≥ | 99.3 | 99.0 | 98.0 |

| Moisture % ≤ | 0.50 | 1.0 | |

| Ashes % ≤ | 0.03 | 0.05 | 0.08 |

| Aqueous Solution Appearance | Accepted | — | |

| Heavy Metal as Pb2+ % ≤ | 0.001 | — | |

| Chloride as Cl- % | 0.015 | — | |

| Sulphate as SO42- % ≤ | 0.02 | — | |

| Ammonium as NH4+ % ≤ | 0.001 | — | |

Package:packed with film plastic bags, then wrapped in woven bags or other applicable package material, net weight of each bag: 25kg; stored in dry, clean and well ventilated warehouse, stored outdoors prohibited, prevented from wetting. The following info. shall be marked on bags: brand, standard no., manufacturer, product name, production lot, net and FMR marks.

Calculate in per ton product

| No | Name | Unit | Consumption quota | Remark |

|---|---|---|---|---|

| 1 | Formaldehyde (37%) | t | 3.5 | As per methanol, the consumption quota is 1.575t |

| 2 | Ammonia (100%) | kg | 530 | Without oil and water |

| 3 | Recycling cooling water | t | 150 | Water temperature≤31℃ P≥0.4MPa |

| 4 | Steam | t | 3.0-4.0 | P≥0.6MPa |

| 5 | Power | kW×h | 150 | 380/220V 50Hz |

| 6 | Demineralized water | t | 1~2 | Meet the water quality standard (Grade III) |

| 工 程 名 称 | 型 号 及 参 数 | 生产线条数 | 完成日期 |

|---|---|---|---|

| Iran Petroavid | 5000 tpa Hexamine Plant | 2 | 2008.3 |

| Iran Gameron | 5000 tpa Hexamine Plant | 2 | 2008.4 |

| Shandong Tuobo Chemical CO., Ltd | 20000 tpa Hexamine Plant | 1 | 2010.3 |

| Xinjiang Ruiyuantong Chemical CO., Ltd | 20000 tpa Hexamine Plant | 1 | 2014.06 |

Overview-Gas Phase Process

Hexamine is fully called hexamethylenetetramine. The structural formula is (CH2)6N4, and the molecular weight is 140.19.The main material for hexamine production is formaldehyde and ammonia. There are two kinds of production technologies: liquid phase and gas phase process.

The advantages of gas phase process:

Gas phase process of hexamine is the advanced continuous hexamine production technology. Converse methanol to formaldehyde gas, and directly put to ammonia reactor, having reaction with ammonia in the saturation mother liquid of hexamine, and making hexamine. Gas phase process of hexamine is with advantages of short route, less side reaction and high purity. The operation of recycling the over ammonia gas and methanol can remove the environmental pollution and decrease the consumption. The heat can be comprehensively and reasonably used, with the continuous production and high automation degree.

Brief introduction on the technological process of hexamine gas phase process:

1.Reaction Unit

Ammonia and the formaldehyde gas from the formaldehyde plant come into ammonia reactor. Formaldehyde and ammonia have bubble condensation in the mother liquid, making hexamine solution.

2.The gas absorption unit of Ammonia reactor

The ammonification reaction takes use of the sensible heat brought by formaldehyde and the hexamine reaction heat, having water evaporated under the certain temperature and vacuum condition. The evaporating water, with inert gas such as ammonia gas, hydrogen and nitrogen gas, come into Ammonia Absorption Tower. The top tower gas of the Ammonia Absorption Tower, via Air Cooler and Vacuum Buffer Tank, was put into Off-gas Absorption Tower by vacuum pump. The top tower gas of the Off-gas Absorption Tower is sent to Off-gas Biller for burning and making steam, or emptying.

3.Dilute ammonia treatment unit

The bottom liquid of the Ammonia Absorption Tower and Off-gas Absorption Tower has little ammonia. Put dilute ammonia to the cooler and preheater, separately located in the top and bottom of the AM Stripper, and heat the tower bottom by steam. The ammonia and water discharged from the tower top returns to ammonification reactor, having reaction. The desalted water discharged from the bottom of tower can be continuously used, such as being added to the cooling tower.

4.Hexamine crystallization

The solid and liquid phase hexamine of the Ammonification reactor bottom is put to Mother Liquid Seal Trough, and then pumped into Crystallization Head Tank. The solid phase hexamine of the trough bottom comes into centrifuge for separation, and the mother liquid is put to mother liquid circulation tank. The hexamine coming out of centrifuge is the solid.

5. Drying unit

The solid hexamine from the centrifuge is unloaded to the surge bin, via special conveyor sent to the air-flow dryer. The hexamine after drying is separated by the Cyclone Separator, and then sent to package unit.

6. Off-has washing unit

The gas discharged from Cyclone Separator comes into Off-gas Washing Tower,after washed and absorbing dust, it will be emptied by the induced draft fan, the liquid from the bottom of tower will be sent to Off-gas Washing Tower.

Hexamine is fully called hexamethylenetetramine. The structural formula is (CH2)6N4, and the molecular weight is 140.19.The main material for hexamine production is formaldehyde and ammonia. There are two kinds of production technologies: liquid phase and gas phase process.

The advantages of gas phase process:

Gas phase process of hexamine is the advanced continuous hexamine production technology. Converse methanol to formaldehyde gas, and directly put to ammonia reactor, having reaction with ammonia in the saturation mother liquid of hexamine, and making hexamine. Gas phase process of hexamine is with advantages of short route, less side reaction and high purity. The operation of recycling the over ammonia gas and methanol can remove the environmental pollution and decrease the consumption. The heat can be comprehensively and reasonably used, with the continuous production and high automation degree.

Brief introduction on the technological process of hexamine gas phase process:

1.Reaction Unit

Ammonia and the formaldehyde gas from the formaldehyde plant come into ammonia reactor. Formaldehyde and ammonia have bubble condensation in the mother liquid, making hexamine solution.

2.The gas absorption unit of Ammonia reactor

The ammonification reaction takes use of the sensible heat brought by formaldehyde and the hexamine reaction heat, having water evaporated under the certain temperature and vacuum condition. The evaporating water, with inert gas such as ammonia gas, hydrogen and nitrogen gas, come into Ammonia Absorption Tower. The top tower gas of the Ammonia Absorption Tower, via Air Cooler and Vacuum Buffer Tank, was put into Off-gas Absorption Tower by vacuum pump. The top tower gas of the Off-gas Absorption Tower is sent to Off-gas Biller for burning and making steam, or emptying.

3.Dilute ammonia treatment unit

The bottom liquid of the Ammonia Absorption Tower and Off-gas Absorption Tower has little ammonia. Put dilute ammonia to the cooler and preheater, separately located in the top and bottom of the AM Stripper, and heat the tower bottom by steam. The ammonia and water discharged from the tower top returns to ammonification reactor, having reaction. The desalted water discharged from the bottom of tower can be continuously used, such as being added to the cooling tower.

4.Hexamine crystallization

The solid and liquid phase hexamine of the Ammonification reactor bottom is put to Mother Liquid Seal Trough, and then pumped into Crystallization Head Tank. The solid phase hexamine of the trough bottom comes into centrifuge for separation, and the mother liquid is put to mother liquid circulation tank. The hexamine coming out of centrifuge is the solid.

5. Drying unit

The solid hexamine from the centrifuge is unloaded to the surge bin, via special conveyor sent to the air-flow dryer. The hexamine after drying is separated by the Cyclone Separator, and then sent to package unit.

6. Off-has washing unit

The gas discharged from Cyclone Separator comes into Off-gas Washing Tower,after washed and absorbing dust, it will be emptied by the induced draft fan, the liquid from the bottom of tower will be sent to Off-gas Washing Tower.

https://drive.google.com/file/d/137Ca6icYSyibU6SowfLEhAjqeCdLVxIF/view?usp=sharing

Products

TOP