Principle

It's a wet process milling equipment which can produce continuously, its working principle is the power delivered from high-speed rotor to milling medium and liquid product, through mutual colliding and laminating, ultrafine size can be

achieved.

Characteristics

• High flux―technology imported from Germany: static centrifugal discharging devices, large discharge area with high output.

• Double mechanical seal, lubricating liquid dissolves with material, safe and reliable.

• Grinding area is made of special anti-wearing alloy ensuring long service life.

• Cooling efficiency: segmented double helix waterway which is more advantageous to the energy exchange. Cooling efficiency is 2 times better than ordinary types.

• Intelligent double mechanical seals: German mechanical seal technology, imported- fluorine sealing rings can resist different solvents.

• Grinding efficiency: increased to more than 30% compared with regular models, the combination of the disperser can rapidly improve dispersion efficiency. The grinding medium can be superfine size to be more efficient.

Product Advantages

• Low energy consumption ratio, High cost-effective

• With large and small belts to conveyor driving force from the motor the main shaft, it is easy to start. The grinding discs are specially designed to have higher effiency and lower electricconsumption. It is machine with higher performance-cost ratio among the grinding machines.Easy to clean and operate

• The machine is with integrated on-spot control panel, easy to do operation. Following structures to make it is easy to clean the grinding chamber and the beads to produce materials with different color and varieties with beads collection hopper, the pulley gear device to make it easy for assemble and disassemble the grinding chamber and frame.Safe monitor, stable finished product

• Grinding chamber is with cooling jackets. Input cooling water into the jacket when running to have good cooling result, normally the temperature increase will be within 10C.

• The machine is with temperature and monitor control. With settable protection value to ensure the quality of the finished products.

• Full specification, can be customized

• Specifications ranges from 30L to 100L, which can be customized to be Exproof type. Grinding chambers made of Polyurethane or Zirconium are in option to ensure its anti-abrasiveness and alsoto prevent materials from metal pollution.

Working Principle

The delivery pump circulates the materials in the tank and the materials in the grinding chamber. The discs drive the grinding medium inside the grinding chamber to do irregular movements in all direction to put the materials under the. action of constant collision and friction. At same time, the materials are separated from the grinding medium by the sieve and keep circulating from the tank to the grinding chamber to obtain smaller particle size, narrower particle size range.

|

Type/Parameter |

Motor power |

Barrel capacity |

Pump flux |

Cooling water |

Production capacity |

Milling medium |

Overall size |

||

|

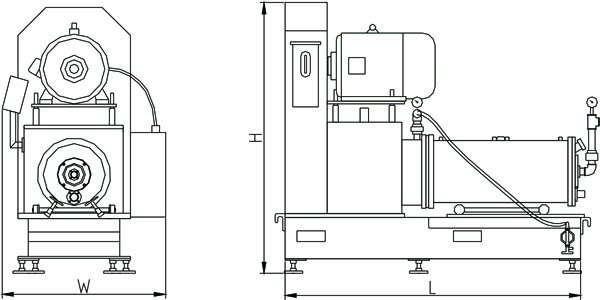

L |

W |

H |

|||||||

|

FSP-30 |

22 |

30 |

2~17 |

1.5~2 |

80~600 |

0.4~2.0 |

1620 |

930 |

1610 |

|

FSP-50 |

30 |

50 |

3~22 |

2~2.5 |

100~800 |

0.4~2.0 |

1780 |

930 |

1780 |

|

FSP-60 |

37 |

60 |

3~22 |

2~2.5 |

100~1000 |

0.4~2.0 |

2000 |

1900 |

1000 |

|

FSP-100 |

37/55 |

100 |

5~40 |

2.5~3 |

200~1500 |

0.4~2.0 |

2100 |

1170 |

1930 |

|

FSP-200 |

110 |

200 |

8~60 |

4~5.5 |

500~2500 |

0.4~2.0 |

2850 |

2380 |

1400 |