• If the material is supplied via vibratory chute, it is possible to separate weakly magnetic particles, such as particles from machined stainless steel, and even paramagnetic particles. Due to the continuous cleaning, the drum magnet is very suitable for product flows with heavy magnetic particle contamination.

•We supply various drum magnets:

• For fine or coarse product streams

• For small or large capacities

• For material containing little/lots of magnetic particles

• For various industries : From the food industry to recycling

• The standaed magnetic drum separator is suitable for coarser raw materials in the plastics and ceramics industries.

• The food/pharma drum magnets have been specifically developed for the food and pharma industries. They have a small capacity yet filer smaller Fe (and even weak magnetic) particles out of a product stream.

• The lenastar even filter out paramagnetic particles such as stones, mud, insect excrement, etc. From your dried raw material (e.e. tea, spices).

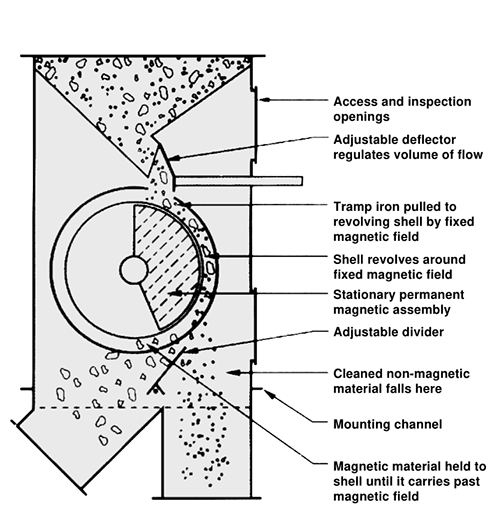

• A drum magnet is a stationary (180 degree ) magnet segment, around which a stainless steel drum rotates. The magnet attracts magnetic particles that are in the product. The drum carries the attached particles with it to the bottom of the drum. There the particles drop off and can be collected and carried away. For a strongly magnetic particles, carriers are placed on the drum to "push" the particles out of the magnetic field. The advantage of a drum magnet is that it is a continuous cleaning/separating system, in which it is not necessary to stop the product to remove the magnetic particles.

|

Drum Diameter |

Drum Width |

Capacity |

A |

B |

C |

D |

E |

E1 |

F |

Approx Weight |

||||||||||

|

in |

in |

mm |

ft3/h |

m3/hr |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

lb |

kg |

|

12 (305mm) 45 rpm |

12 |

305 |

1000 |

28 |

15-3/4 |

400 |

4-1/4 |

108 |

7-7/8 |

200 |

27-7/8 |

708 |

1-15/16 |

49 |

1-15/16 |

49 |

14 |

356 |

180 |

82 |

|

14 |

356 |

1200 |

34 |

17-3/4 |

451 |

4-1/4 |

108 |

7-7/8 |

200 |

29-7/8 |

759 |

1-15/16 |

49 |

1-15/16 |

49 |

14 |

356 |

200 |

91 |

|

|

16 |

406 |

1400 |

40 |

19-3/4 |

502 |

4-1/4 |

108 |

7-7/8 |

200 |

31-7/8 |

810 |

1-15/16 |

49 |

1-15/16 |

49 |

14 |

356 |

225 |

102 |

|

|

18 |

457 |

1600 |

45 |

21-3/4 |

552 |

4-1/4 |

108 |

7-7/8 |

200 |

33-7/8 |

860 |

1-15/16 |

49 |

1-15/16 |

49 |

14 |

356 |

260 |

118 |

|

|

20 |

508 |

1800 |

50 |

23-3/4 |

603 |

4-1/4 |

108 |

7-7/8 |

200 |

35-7/8 |

911 |

1-15/16 |

49 |

1-15/16 |

49 |

14 |

356 |

285 |

129 |

|

|

24 |

610 |

2200 |

62 |

27-3/4 |

705 |

4-1/4 |

108 |

7-7/8 |

200 |

38-7/8 |

1013 |

1-15/16 |

49 |

1-15/16 |

49 |

14 |

356 |

310 |

141 |

|

|

30 |

762 |

2800 |

80 |

33-3/4 |

857 |

4-1/4 |

108 |

7-7/8 |

200 |

45-7/8 |

1165 |

1-15/16 |

49 |

1-15/16 |

49 |

14 |

356 |

350 |

159 |

|

|

36 |

915 |

3300 |

93 |

39-3/4 |

1010 |

4-1/4 |

108 |

7-7/8 |

200 |

51-7/8 |

1318 |

1-15/16 |

49 |

1-15/16 |

49 |

14 |

356 |

390 |

177 |

|

|

42 |

1067 |

3900 |

110 |

45-3/4 |

1162 |

4-1/4 |

108 |

7-7/8 |

200 |

57-7/8 |

1470 |

1-15/16 |

49 |

1-15/16 |

49 |

14 |

356 |

430 |

195 |

|

|

15 (381mm) 40 rpm |

12 |

305 |

1250 |

35 |

15-3/4 |

400 |

4-9/16 |

116 |

9 |

229 |

29-5/16 |

745 |

2-7/16 |

62 |

2-7/16 |

62 |

16-3/4 |

425 |

205 |

95 |

|

14 |

356 |

1500 |

42 |

17-3/4 |

451 |

4-9/16 |

116 |

9 |

229 |

31-5/16 |

795 |

2-7/16 |

62 |

2-7/16 |

62 |

16-3/4 |

425 |

225 |

100 |

|

|

16 |

406 |

1750 |

50 |

19-3/4 |

502 |

4-9/16 |

116 |

9 |

229 |

33-5/16 |

846 |

2-7/16 |

62 |

2-7/16 |

62 |

16-3/4 |

425 |

245 |

110 |

|

|

18 |

457 |

2000 |

57 |

21-3/4 |

552 |

4-9/16 |

116 |

9 |

229 |

35-5/16 |

897 |

2-7/16 |

62 |

2-7/16 |

62 |

16-3/4 |

425 |

265 |

120 |

|

|

20 |

508 |

2200 |

62 |

23-3/4 |

603 |

4-9/16 |

116 |

9 |

229 |

37-5/16 |

948 |

2-7/16 |

62 |

2-7/16 |

62 |

16-3/4 |

425 |

290 |

130 |

|

|

24 |

610 |

2700 |

76 |

27-3/4 |

705 |

4-9/16 |

116 |

9 |

229 |

41-5/16 |

1049 |

2-7/16 |

62 |

2-7/16 |

62 |

16-3/4 |

425 |

350 |

160 |

|

|

30 |

762 |

3400 |

96 |

33-3/4 |

857 |

4-9/16 |

116 |

9 |

229 |

47-5/16 |

1202 |

2-7/16 |

62 |

2-7/16 |

62 |

16-3/4 |

425 |

425 |

195 |

|

|

36 |

915 |

4100 |

116 |

39-3/4 |

1010 |

4-9/16 |

116 |

9 |

229 |

53-5/16 |

1354 |

2-7/16 |

62 |

2-7/16 |

62 |

16-3/4 |

425 |

520 |

235 |

|

|

42 |

1067 |

4800 |

136 |

45-3/4 |

1162 |

4-9/16 |

116 |

9 |

229 |

59-5/16 |

1507 |

2-7/16 |

62 |

2-7/16 |

62 |

16-3/4 |

425 |

620 |

280 |

|

|

48 |

1219 |

5500 |

156 |

51-3/4 |

1314 |

4-9/16 |

116 |

9 |

229 |

"65-5/16 |

1659 |

2-7/16 |

62 |

2-7/16 |

62 |

16-3/4 |

425 |

715 |

325 |

|

|

18 (457mm) 35 rpm |

12 |

305 |

1600 |

45 |

15-3/4 |

400 |

4-9/16 |

116 |

9 |

229 |

29-5/16 |

745 |

2-7/16 |

62 |

2-7/16 |

62 |

20-1/2 |

521 |

240 |

110 |

|

14 |

356 |

1900 |

54 |

17-3/4 |

451 |

4-9/16 |

116 |

9 |

229 |

31-5/16 |

795 |

2-7/16 |

62 |

2-7/16 |

62 |

20-1/2 |

521 |

270 |

120 |

|

|

16 |

406 |

2200 |

62 |

19-3/4 |

502 |

4-9/16 |

116 |

9 |

229 |

33-5/16 |

846 |

2-7/16 |

62 |

2-7/16 |

62 |

20-1/2 |

521 |

300 |

135 |

|

|

18 |

457 |

2500 |

71 |

21-3/4 |

552 |

4-9/16 |

116 |

9 |

229 |

35-5/16 |

897 |

2-7/16 |

62 |

2-7/16 |

62 |

20-1/2 |

521 |

330 |

150 |

|

|

20 |

508 |

2800 |

79 |

23-3/4 |

603 |

4-9/16 |

116 |

9 |

229 |

37-5/16 |

948 |

2-7/16 |

62 |

2-7/16 |

62 |

20-1/2 |

521 |

360 |

165 |

|

|

24 |

610 |

3400 |

96 |

27-3/4 |

705 |

4-9/16 |

116 |

9 |

229 |

41-5/16 |

1049 |

2-7/16 |

62 |

2-7/16 |

62 |

20-1/2 |

521 |

410 |

185 |

|

|

30 |

762 |

4300 |

122 |

33-3/4 |

857 |

4-9/16 |

116 |

9 |

229 |

47-5/16 |

1202 |

2-7/16 |

62 |

2-7/16 |

62 |

20-1/2 |

521 |

510 |

230 |

|

|

36 |

915 |

5200 |

147 |

39-3/4 |

1010 |

4-9/16 |

116 |

9 |

229 |

53-5/16 |

1354 |

2-7/16 |

62 |

2-7/16 |

62 |

20-1/2 |

521 |

610 |

275 |

|

|

42 |

1067 |

6100 |

173 |

45-3/4 |

1162 |

4-9/16 |

116 |

9 |

229 |

59-5/16 |

1507 |

2-7/16 |

62 |

2-7/16 |

62 |

20-1/2 |

521 |

710 |

320 |

|

|

48 |

1219 |

7000 |

198 |

51-3/4 |

1314 |

4-9/16 |

116 |

9 |

229 |

"65-5/16 |

1659 |

2-7/16 |

62 |

2-7/16 |

62 |

20-1/2 |

521 |

810 |

365 |

|

Permanent and Powerful magnetic force with long magnetic distance..

Single-layer, multi-layer optional, Multiple layers preferable bring better separation effect.

• A wide range of types and sizes of products are provided, and do personalized design according to customer requirements.

• Offer the Professional Drawing according to the working environment.

|

24 (610mm) 30 rpm |

18 |

457 |

3700 |

105 |

23-1/2 |

597 |

9 |

229 |

11 |

279 |

43-1/2 |

1105 |

2-15/16 |

75 |

2-7/16 |

62 |

28 |

711 |

940 |

425 |

|

20 |

508 |

4200 |

119 |

25-1/2 |

648 |

9 |

229 |

11 |

279 |

45-1/2 |

1156 |

2-15/16 |

75 |

2-7/16 |

62 |

28 |

711 |

962 |

435 |

|

|

24 |

610 |

5100 |

145 |

29-1/2 |

749 |

9 |

229 |

11 |

279 |

49-1/2 |

1257 |

2-15/16 |

75 |

2-7/16 |

62 |

28 |

711 |

1020 |

465 |

|

|

30 |

762 |

6500 |

185 |

35-1/2 |

902 |

9 |

229 |

11 |

279 |

55-1/2 |

1410 |

2-15/16 |

75 |

2-7/16 |

62 |

28 |

711 |

1080 |

490 |

|

|

36 |

915 |

7800 |

220 |

41-1/2 |

1054 |

9 |

229 |

11 |

279 |

61-1/2 |

1562 |

2-15/16 |

75 |

2-7/16 |

62 |

28 |

711 |

1380 |

625 |

|

|

42 |

1067 |

9200 |

260 |

47-1/2 |

1206 |

9 |

229 |

11 |

279 |

67-1/2 |

1715 |

2-15/16 |

75 |

2-7/16 |

62 |

28 |

711 |

1600 |

725 |

|

|

48 |

1219 |

10500 |

300 |

53-1/2 |

1359 |

9 |

229 |

11 |

279 |

73-1/2 |

1867 |

2-15/16 |

75 |

2-7/16 |

62 |

28 |

711 |

1810 |

820 |

|

|

54 |

1372 |

11900 |

340 |

59-1/2 |

1511 |

9 |

229 |

11 |

279 |

79-1/2 |

2019 |

2-15/16 |

75 |

2-7/16 |

62 |

28 |

711 |

2020 |

915 |

|

|

60 |

1524 |

13200 |

375 |

65-1/2 |

1664 |

9 |

229 |

11 |

279 |

85-1/2 |

2172 |

2-15/16 |

75 |

2-7/16 |

62 |

28 |

711 |

2330 |

1055 |

|

|

30 (762mm) 30 rpm |

24 |

610 |

7200 |

205 |

34-1/2 |

876 |

9 |

229 |

12 |

305 |

55-1/2 |

1410 |

3-7/16 |

87 |

2-15/16 |

75 |

35 |

889 |

1788 |

810 |

|

30 |

762 |

9200 |

260 |

40-1/2 |

1029 |

9 |

229 |

12 |

305 |

61-1/2 |

1562 |

3-7/16 |

87 |

2-15/16 |

75 |

35 |

889 |

2072 |

940 |

|

|

36 |

915 |

11000 |

315 |

46-1/2 |

1180 |

9 |

229 |

12 |

305 |

67-1/2 |

1715 |

3-7/16 |

87 |

2-15/16 |

75 |

35 |

889 |

2262 |

1025 |

|

|

42 |

1067 |

13000 |

370 |

52-1/2 |

1334 |

9 |

229 |

12 |

305 |

73-1/2 |

1867 |

3-7/16 |

87 |

2-15/16 |

75 |

35 |

889 |

2560 |

1160 |

|

|

48 |

1219 |

14900 |

420 |

58-1/2 |

1486 |

9 |

229 |

12 |

305 |

79-1/2 |

2019 |

3-7/16 |

87 |

2-15/16 |

75 |

35 |

889 |

2840 |

1290 |

|

|

54 |

1372 |

16800 |

475 |

64-1/2 |

1638 |

9 |

229 |

12 |

305 |

85-1/2 |

2172 |

3-7/16 |

87 |

2-15/16 |

75 |

35 |

889 |

3190 |

1445 |

|

|

60 |

1524 |

18700 |

530 |

70-1/2 |

1791 |

9 |

229 |

12 |

305 |

91-1/2 |

2324 |

3-7/16 |

87 |

2-15/16 |

75 |

35 |

889 |

3665 |

1660 |

-

Catalogues

- Magnetic Bar

- Magnetic Grid

- Drawer Magnetic Separator

- Rotary Magnetic Separator

- Self-Cleaning Drawer Magnetic Separator

- Liquid Permanent Magnetic Filters

- Plate Magnets / Suspended Magnets

- Magnetic Pulley

- The Suspended Magnetic Separator

- The Strongest Magnetic Roll Separators

- Drum Magnetic Separators

- The Magnetic Conveyor

- The Eletromagnetic Separator for Fine Powder

- The Electromagnetic Separator For Slurry

- The Eddy Current Separator

- Magnet