TaiXiong Magnet is a professional magnet and magnetic separator manufacturer. We have three factories in China, we have been magnet manufacture over than 15 years. Our Major product is Rare earth magnet, Rubber magnet and Magnetic separator.

-

Self-Cleaning Drawer Magnetic Separator

Self-Cleaning Drawer Magnetic Separator will absorb and clean iron automatically, which is major for the material with much iron, clean the iron is convenient and quickly, the air cylinder pulls the magnetic rod layer by layer, the iron adsorbed on the magnetic rod automatically falls off, and the w

-

Rotary Magnetic Separator

The rotary type magnetic separator is composed of a ring-shaped magnetic grid, a stainless steel case and a geared motor. The rotary type magnetic separator drives the ring-shaped magnetic grid to rotate by the gear motor, thereby effectively preventing the material from bridging when flowing throug

6

- Contacter: 0086-021-57599048

- Tel: 0086-021-57599046

- Fax: 0086-021-57599045

- Email: Joannazhou@taixiongmagnet.com

-

Company Address:

No.334 Xinghuo Road, QianQiao Town, FengXian District, Shanghai, China

Self-Cleaning Drawer Magnetic Separator

Self-Cleaning Drawer Magnetic Separator will absorb and clean iron automatically, which is major for the material with much iron, clean the iron is convenient and quickly, the air cylinder pulls the magnetic rod layer by layer, the iron adsorbed on the magnetic rod automatically falls off, and the work is continuously, and the raw materials can continue to work when the iron is extracted one by one without stopping the feeding.

The material is fed from the feed port of the magnetic separator and passes through the permanent magnet bar in the magnetic separator. The iron of the material is adsorbed on the magnetic bar by magnetic force, and the non-magnetic mineral particles pass through the magnetic bar and are discharged from the discharge port; At the same time, the permanent magnet bar is pulled layer by layer through the cylinder device, so that the ferromagnetic substance adsorbed on the permanent magnet bar is automatically separated and discharged from the iron removal port.

Self-Cleaning Drawer Magnetic Separator

Self-Cleaning Drawer Magnetic Separator will absorb and clean iron automatically, which is major for the material with much iron, clean the iron is convenient and quickly, the air cylinder pulls the magnetic rod layer by layer, the iron adsorbed on the magnetic rod automatically falls off, and the work is continuously, and the raw materials can continue to work when the iron is extracted one by one without stopping the feeding.

The material is fed from the feed port of the magnetic separator and passes through the permanent magnet bar in the magnetic separator. The iron of the material is adsorbed on the magnetic bar by magnetic force, and the non-magnetic mineral particles pass through the magnetic bar and are discharged from the discharge port; At the same time, the permanent magnet bar is pulled layer by layer through the cylinder device, so that the ferromagnetic substance adsorbed on the permanent magnet bar is automatically separated and discharged from the iron removal port.

Rotary Magnetic Separator

The rotary type magnetic separator is composed of a ring-shaped magnetic grid, a stainless steel case and a geared motor. The rotary type magnetic separator drives the ring-shaped magnetic grid to rotate by the gear motor, thereby effectively preventing the material from bridging when flowing through the rotatory magnetic separator. Blockage and the like occur to efficiently remove iron impurities in the loose agglomerated material. Rotary type magnetic separator is mainly used for sorting fine iron impurities in powder materials with relatively poor fluidity and easy to accumulate. These materials are more likely to be blocked or piled up by using traditional magnetic grid or drawer type magnetic separator. Widely used in food, food additives, pharmaceuticals, fine chemicals, lithium battery positive and negative materials, pigments, carbon black, flame retardants and other industrial production lines.

Rotary Magnetic Separator

The rotary type magnetic separator is composed of a ring-shaped magnetic grid, a stainless steel case and a geared motor. The rotary type magnetic separator drives the ring-shaped magnetic grid to rotate by the gear motor, thereby effectively preventing the material from bridging when flowing through the rotatory magnetic separator. Blockage and the like occur to efficiently remove iron impurities in the loose agglomerated material. Rotary type magnetic separator is mainly used for sorting fine iron impurities in powder materials with relatively poor fluidity and easy to accumulate. These materials are more likely to be blocked or piled up by using traditional magnetic grid or drawer type magnetic separator. Widely used in food, food additives, pharmaceuticals, fine chemicals, lithium battery positive and negative materials, pigments, carbon black, flame retardants and other industrial production lines.

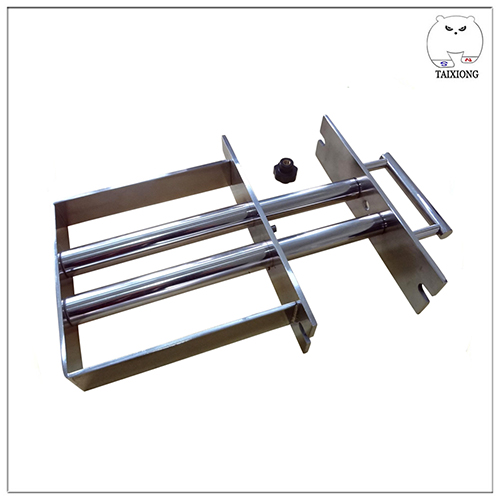

Magnetic Grid

• Magnetic grid is composed of a series of parallel magnetic bars, magnetic bars spaced from each other and firmly fixed to the grid bracket or frame. Magnetic grid can be designed into a variety of shapes, such as square, circular, drawer, wing, rotary and so on, to match the different shapes of hoppers, chutes, pipes, openings and so on.

• Magnetic separation grids are flexible and efficient magnetic separation devices designed to remove ferromagnetic impurities, weak magnetic iron contaminants, and others in free-flowing, externally-conveyed materials (such as pellets and powders) and other small paramagnetic particles, which can effectively purify the material, improve material quality, and protect the downstream equipment from the damage of the ferrous, to ensure the efficient operation of processing equipment.

Magnetic Grid

• Magnetic grid is composed of a series of parallel magnetic bars, magnetic bars spaced from each other and firmly fixed to the grid bracket or frame. Magnetic grid can be designed into a variety of shapes, such as square, circular, drawer, wing, rotary and so on, to match the different shapes of hoppers, chutes, pipes, openings and so on.

• Magnetic separation grids are flexible and efficient magnetic separation devices designed to remove ferromagnetic impurities, weak magnetic iron contaminants, and others in free-flowing, externally-conveyed materials (such as pellets and powders) and other small paramagnetic particles, which can effectively purify the material, improve material quality, and protect the downstream equipment from the damage of the ferrous, to ensure the efficient operation of processing equipment.

Magnetic Bar

• Magnetic bars are made with rare earth magnet and stainless steel. The magnetic force is 2000-12000 Gs.

• Magnetic Bars are also the building blocks of many magnetic systems and are used to filter product streams for the removal of very fine ferromagnetic and weakly magnetic particles (such as swear debris, rust, stainless steel wear particles, heavy metal impurities as well as plating layer debris from dry or liquid products).

The magnetic bar is also as important inspection tools for the purpose of material quality assurance.

Magnetic Bar

• Magnetic bars are made with rare earth magnet and stainless steel. The magnetic force is 2000-12000 Gs.

• Magnetic Bars are also the building blocks of many magnetic systems and are used to filter product streams for the removal of very fine ferromagnetic and weakly magnetic particles (such as swear debris, rust, stainless steel wear particles, heavy metal impurities as well as plating layer debris from dry or liquid products).

The magnetic bar is also as important inspection tools for the purpose of material quality assurance.