DMMn Plant

Performance

References

Overview

1.4-1 DMMn Quality Index

1.7-1 Raw Material,Utilities Consumption Quota

Process Digram&Layout Drawing

| Project | Index |

|---|---|

| DMMn Content | >99.5% |

| Methanol | <0.5% |

| Methylal Content | <0.01% |

| Appearance | colorless, transparent |

| Sulfur Content | <1ppm |

| Chlorine Content/td> | <1ppm |

| Acidity | ≤7(mgKOH/100ml) |

1.7-1 Raw Material,Utilities Consumption Quota

| NO. | Name | Consumption quota |

|---|---|---|

| 1 | Methanol | 1.4 t/t |

| 2 | Auxiliary Agent | 10 kg/t |

| 3 | Steam | 3.5 t/t |

| 4 | Process Water | 1.2 t/t |

| 5 | Primary Water | 6.3 t/t |

| 6 | Circulating Water | 245.2 t/t |

| 7 | Industrial Electricity | 200 kWh/t |

| 8 | Instrument Air | ~32 Nm3/t |

| 9 | Nitrogen (purge) | ~60 Nm3/hr |

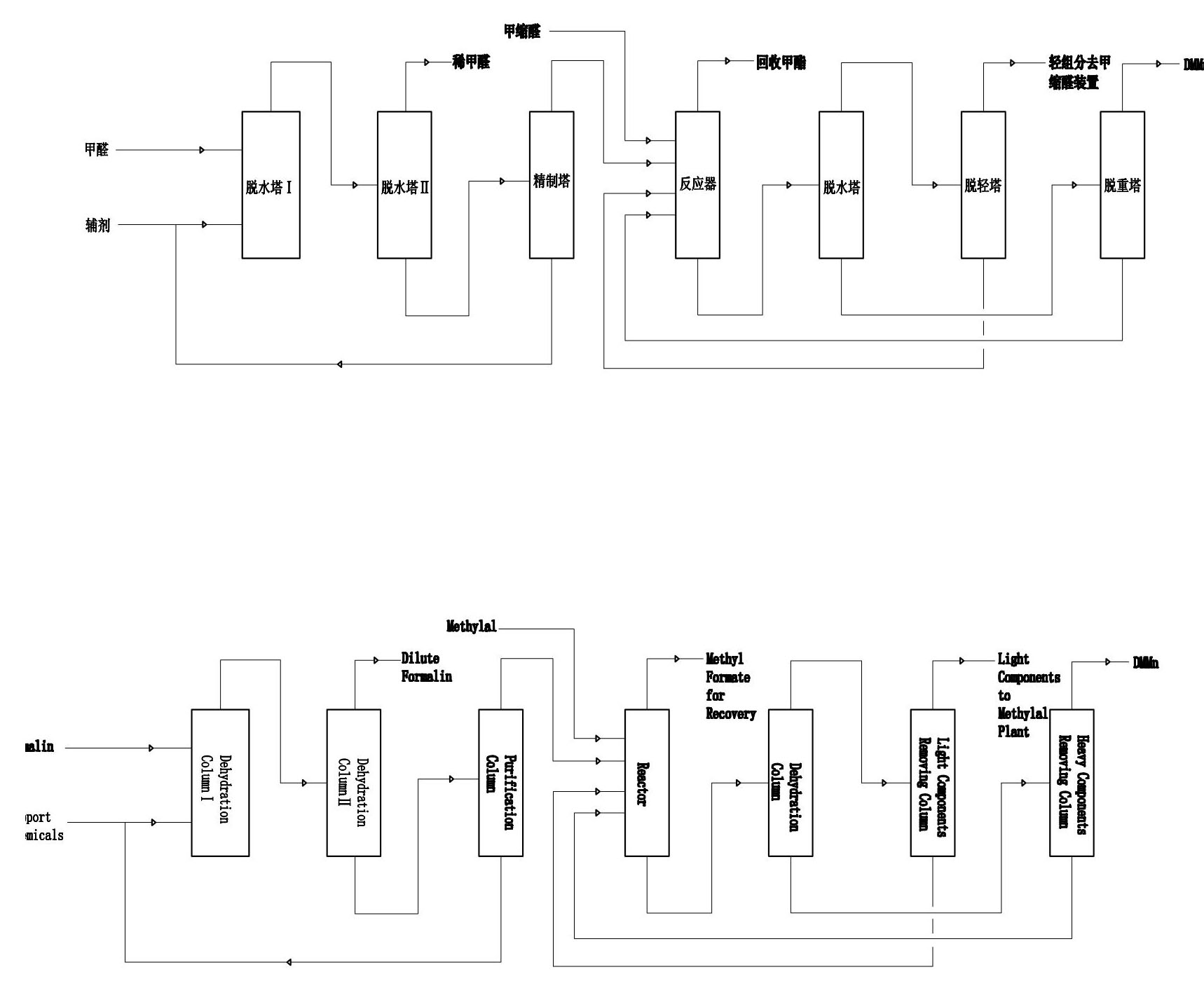

Process Drawing

ProcessEquipment Layout DrawThe chemical name of DMMn is PODE and Polyoxymethylene dimethyl ethers etc. The molecule short form can be expressed asing CH3O(CH2O)nCH3,and the general value selection of n is 2~8. DMMn has better oxygen content ((wt%:42%~51%)and higher Cetane number(≥60, when it is added to the diesel , the diesel flame quality in engineer the can be obviously improved , the thermal efficiency can be improved and the pollution emission can be decreased. Thus it is recognized as the most promising diesel additive

1.1-1 DMMn Basic physical and chemical properties

1.1-2 Main physical and chemical specifications of DMMn and blended diesel

1.1-3 Vehicle Test Data

1.1-4 Rack Test Data

From the above tables, we can see clearly that DMMn has excellent physical and chemical performance parameter.Once 5%~15% of DMMn is added into the diesel, cetane number and engine efficiency in the diesel will be increased effectively,in turn reducing the emissions in the off-gas like PM、CO、NOx.

DMM2, being the good diesel blending component under low-temperature environment,whose boiling point is 105℃,melting point is -69.7℃,flashing point is 23℃ can reduce the freezing point of diesel effectively ;Meanwhile,DMM2 is good clean solvent without aromatic hydrocarbon、cyclic hydrocarbon which can replace the clean organic solvent of benzene and methylbenzene,practical value of DMM2 is very high.

This process adopt formaldehyde and methylal as the raw material to compound DMMn,main equipments are:one set of methanol to formaldehyde plant,one set of methylal plant,one set of DMMn plant.

(1)Refine Formalin

50% concentration formaldehyde enter the climbing film evaporator to get preheated and then come inside the separator to do the vacuum flashing concentration,after it is concentrated to 75%, it is sent to the DMMn Compounding Unit through pump.

(2) DMMn Compounding Unit

The mixed formaldehyde and methylal from refining unit come into the reacting unit first,the reaction mass will go through heavy removing column later and product of column reactor will create DMM3-4 and little heavy constituent products after it is separated. heavy constituent enter the polymerization unitto get to get reacted again.

(3)Purge gas absorption unit

All the purge gas of the factory will enter the purge gas absorptioncolumn,top water of dehydrating towerⅡwill be used as the absorption water meanwhile ,the absorbed the solution consisting of methylal、methanol and formaldehyde will enter the methylal unit.

2)Adopt formaldehyde as raw material whose cost is the lowest.

3)Cause Paraformaldehyde and trioxymethylene plant needn’t be constructed here, the building cost of projects reduce a lot.

4)The most advanced silver contact formaldehyde&high concentration methylal technology is integrated in our company,especially the plant process waste reach domestic first class discharge standard

5)Consumption of material and utilities stays a leading level.

pdf

1.1-1 DMMn Basic physical and chemical properties

| Name | Boiling Point/℃ | Oxygen Content/% | Cetane number | Flash point/℃ | Proportion |

|---|---|---|---|---|---|

| DMM2 | 105 | 45.3 | 63 | 23 | 0.9597 |

| DMM3 | 156 | 47.1 | 78 | 59 | 1.0242 |

| DMM4 | 202 | 48.2 | 90 | 65 | 1.0671 |

| DMM5 | 242 | 49.0 | 100 | 78 | 1.1003 |

| DMM6 | 280 | 49.6 | 104 | 90 | 1.1004 |

| DMM7 | 313 | 50.0 | 104 | ~90 | 1.1006 |

| DMM8 | 320 | 50.3 | 106 | ~90 | 1.1009 |

1.1-2 Main physical and chemical specifications of DMMn and blended diesel

|

Technical Index |

Sample Name | ||

|---|---|---|---|

| (Unit) | Routine diesel | DMMn | blended diesel |

| Density/(g/cm3) | 0.833 | 1.031 | 0.852 |

| kinematic viscosity/(mm2/s) | 4.97 | 1.40 | 3.11 |

| closed-cup flash point/(℃) | 68 | 48 | 55 |

| copper corrosion | 1 | 1 | 1 |

| cold filter plugging point/(℃) | 10 | -20 | 10 |

| Cetane number | 43 | 65 | 48 |

1.1-3 Vehicle Test Data

|

Technical Index |

Sample Name | |||

|---|---|---|---|---|

| (Unit) | 0#diesel | 5%DMMn | 10%DMMn | 15%DMMn |

| Actual max wheel power | 39.88 kW | 43.15 kW | 42.79 kW | 42.66 kW |

| smoke intensity reduce value | 0.0% | 17.8% | 27.7% | 46.1% |

1.1-4 Rack Test Data

| Test item | Emission | National III Diesel | 10%DMMn blended diesel | Deviation% |

|---|---|---|---|---|

| ESC | CO 【g/kW·h】 | 1.88 | 1.56 | -17.02 |

| THC 【g/kW·h】 | 0.15 | 0.14 | -6.67 | |

| NOx 【g/kW·h】 | 8.37 | 8.94 | +6.81 | |

| PM 【g/kW·h】 | 0.05 | 0.03 | -40.0 | |

| ELR | smoke intensity 【m-1】 | 0.46 | 0.22 | -52.17 |

| Remark:Deviation=(10%DMMnblended diesel-national III diesel)/national III diesel×100% | ||||

From the above tables, we can see clearly that DMMn has excellent physical and chemical performance parameter.Once 5%~15% of DMMn is added into the diesel, cetane number and engine efficiency in the diesel will be increased effectively,in turn reducing the emissions in the off-gas like PM、CO、NOx.

DMM2, being the good diesel blending component under low-temperature environment,whose boiling point is 105℃,melting point is -69.7℃,flashing point is 23℃ can reduce the freezing point of diesel effectively ;Meanwhile,DMM2 is good clean solvent without aromatic hydrocarbon、cyclic hydrocarbon which can replace the clean organic solvent of benzene and methylbenzene,practical value of DMM2 is very high.

This process adopt formaldehyde and methylal as the raw material to compound DMMn,main equipments are:one set of methanol to formaldehyde plant,one set of methylal plant,one set of DMMn plant.

(1)Refine Formalin

50% concentration formaldehyde enter the climbing film evaporator to get preheated and then come inside the separator to do the vacuum flashing concentration,after it is concentrated to 75%, it is sent to the DMMn Compounding Unit through pump.

(2) DMMn Compounding Unit

The mixed formaldehyde and methylal from refining unit come into the reacting unit first,the reaction mass will go through heavy removing column later and product of column reactor will create DMM3-4 and little heavy constituent products after it is separated. heavy constituent enter the polymerization unitto get to get reacted again.

(3)Purge gas absorption unit

All the purge gas of the factory will enter the purge gas absorptioncolumn,top water of dehydrating towerⅡwill be used as the absorption water meanwhile ,the absorbed the solution consisting of methylal、methanol and formaldehyde will enter the methylal unit.

Jiangsu Kaimao Chemical Technology Co.,Ltd devote itself to offer a complete set of coal derived clean energy ,whose PODE preparation technology cost least in china ,pls see its process features as below:

1)Adopt solid acid catalyst whose service life is much longer and is much easier to separate itself from the product.2)Adopt formaldehyde as raw material whose cost is the lowest.

3)Cause Paraformaldehyde and trioxymethylene plant needn’t be constructed here, the building cost of projects reduce a lot.

4)The most advanced silver contact formaldehyde&high concentration methylal technology is integrated in our company,especially the plant process waste reach domestic first class discharge standard

5)Consumption of material and utilities stays a leading level.

https://drive.google.com/file/d/10KBwOv9OzV2C2gmK-5ZWADx9veC4MvwR/view?usp=sharing

Products

TOP