Automated Multiple Effect Evaporation System with Crystallizer

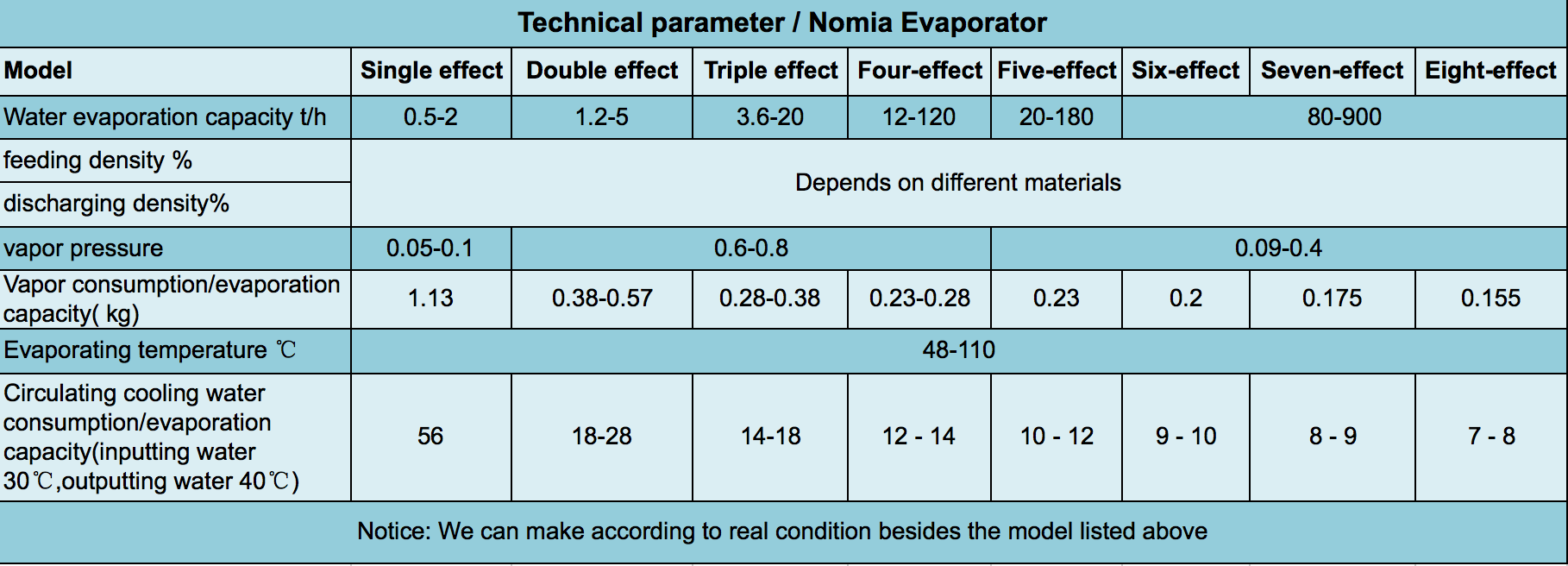

Technical parameter

Application Range

Industrial wastewater treatment, ZLD system.Juice concentration, Chemical crystallization etc.

System components

Evaporator, separator, condenser, vacuum and discharging system, delivery pump, groundwork, PLC, electrical appliance and instruments, valves, pipelines etc.

Multi-effect evaporation concentration equipment

The Live steam as the thermal energy for heating the first effect evaporator then generates secondary vapor which drawn into the second effect evaporator and so on. The multiple evaporators attached to form the whole multiple effect evaporation system. The latent heat will be recycled and reused, thus reducing the energy consumption and enhance thermal efficiency.

Features

- The classic popular evaporation and concentration equipment.

- As the effects increased, the more vapor energy shall be saved.

- Lower up-front investment, but a large amount of vapor energy consumption bring about a strong energy consumption intensity.

- It's suitable to use in low-cost vapor energy field.

- Friendly to the concentration of thermally sensitive material.

Advantages

1.Energy saving: The secondary vapor produced by evaporation can be used as heat steam at the next effect

2.High automatic: Applying PLC automatic control system, automatic control feed time and discharge time, CIP automatic cleaning, automatic generation of operation data, automatic alarm

3.High manufacture standard, high-quality parts, stable to run.

4.The liquid flow down as film, short residence time, evenly heated,

suitable for temperature sensitive or foaming material

The liquid to be concentrated is supplied to the top of the heating

tubes and distributed evenly into the heat tubes through the liquid

distributor, and under the force of gravity and air flow, the liquid flow

down from the top in the form of liquid film.