99.5 Concentration Process

Performance

Overview

Performance - 99.5% Concentration Process

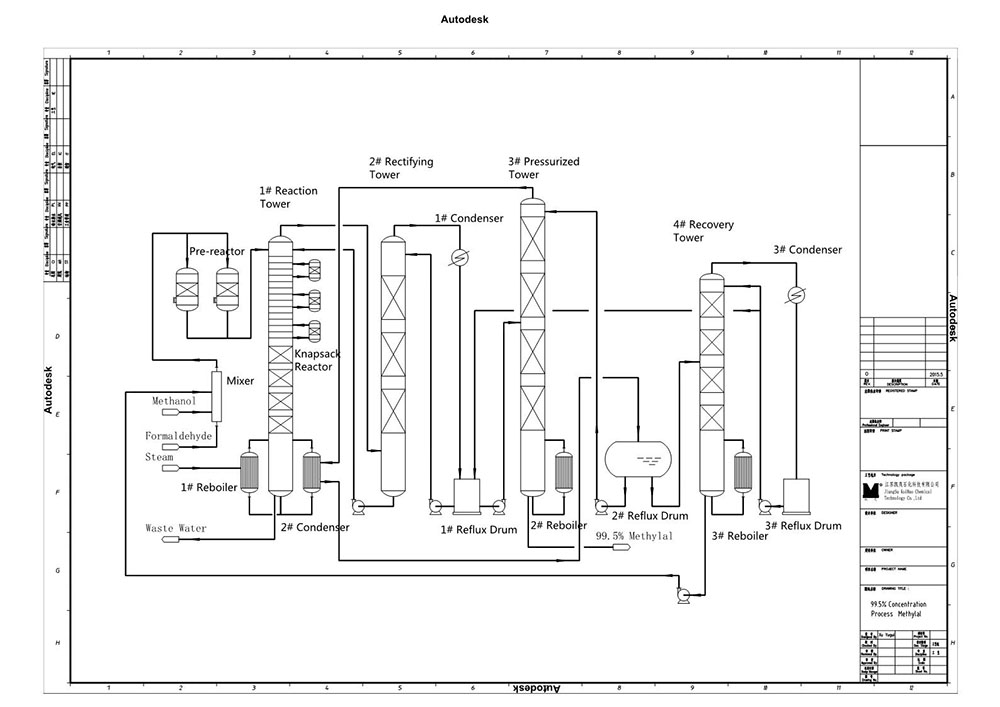

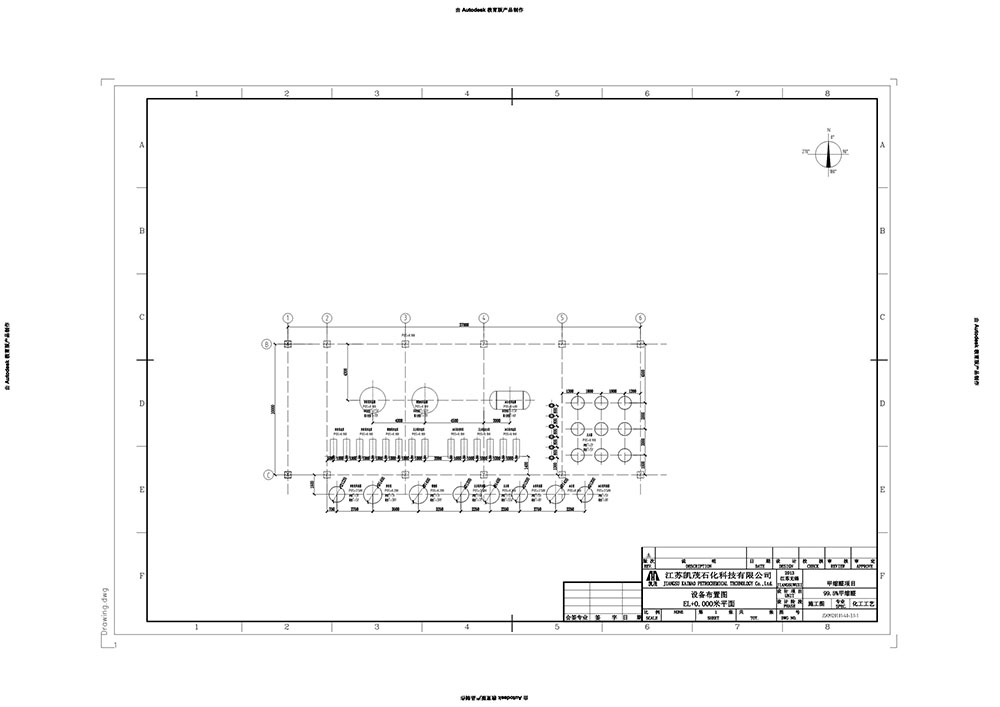

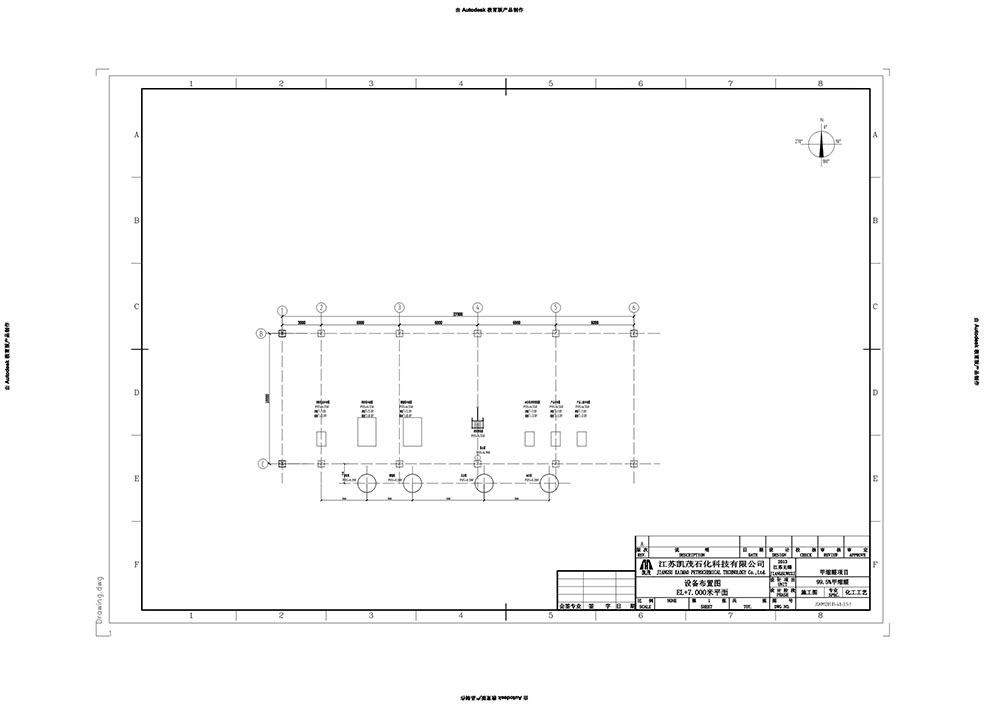

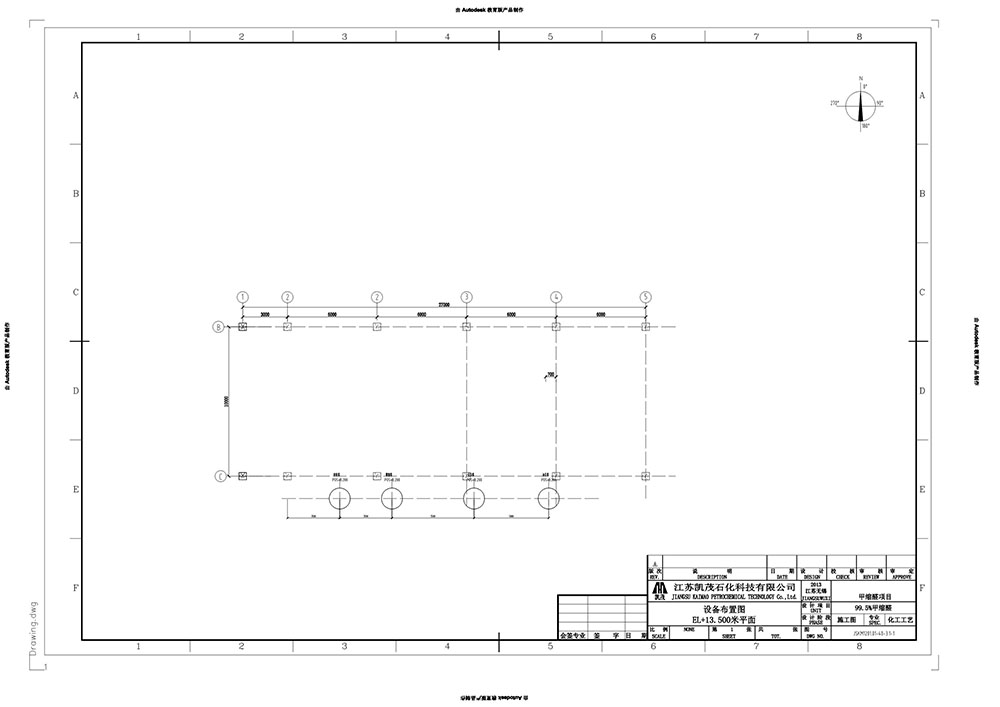

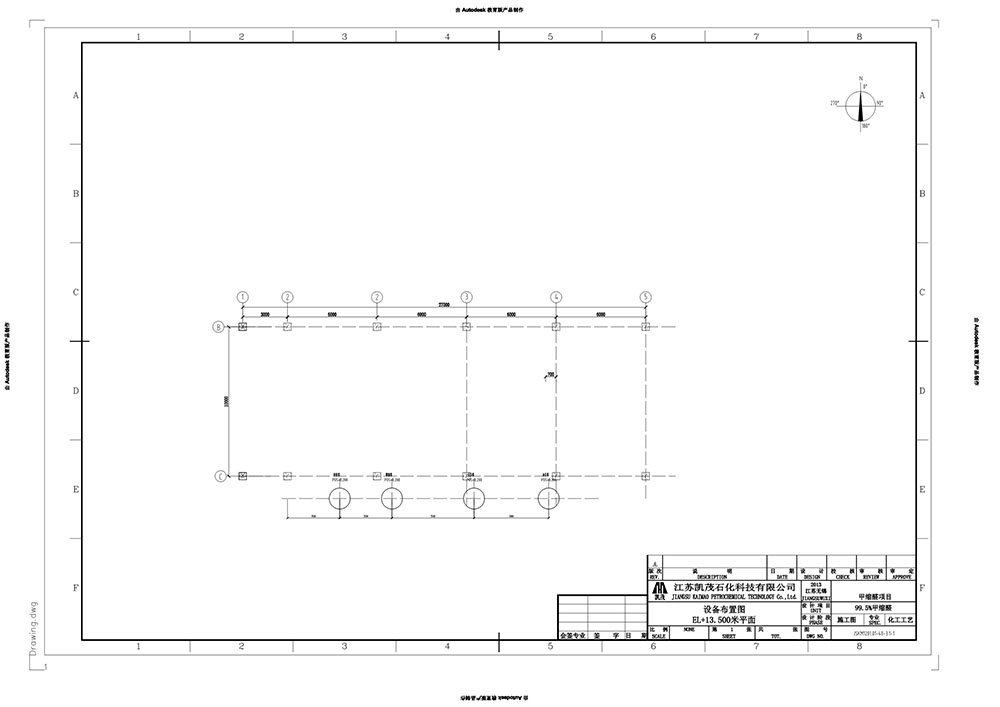

Process Digram&Layout Drawing

References

| No. | Item | Rate of expenditure/th> | Remark |

|---|---|---|---|

| 一 | Raw material and auxiliary material | ||

| 1 | Formaldehyde(37%) | 1.06T/T | |

| 2 | Methanol(99.5%) | 0.84T/T | |

| 二 | Utilities | ||

| 1 | Industrial feeding water t≤25℃ | Intermittent flushing | |

| 2 | Circulating water t≤32℃,△t=8℃, Circulating quantity per hour | 115.2T/T | |

| 3 | Power(380V) | 60kWh/T | |

| 4 | Low pressure steam P=0.25MPa(G) | 750kg/T | |

| Medium pressure steam P=0.8MPa(G) | 550kg/吨 |

| Project | Type and parameter | Production line | Finish date |

|---|---|---|---|

| Wuhan Jiazhou SSTPC | 10000tpa98.5% methylal plant | 1 | 2010.4 |

| Fujian Changqing Chemical Co., Ltd | 30000tpa methylal plant | 1 | 2010.5 |

| Shandong Tuobo Haoyuan Chemical Co., Ltd | 30000tpa methylal plant | 1 | 2010.5 |

| Sanming Jifu Chemical Co., Ltd | 50000tpa methylal plant | 1 | 2010.8 |

| Chengdu Liantai Chemical Co., Ltd | 20000tpa methylal plant | 1 | 2010.8 |

| Wuhan Jiazhou SSTPC | 1000tpa methylal plant | 1 | 2010.10 |

| Maoming City ZhongguangChemical Co., Ltd |

60000tpa formaldehyde plant 30000tpa methylal plant |

2 | 2010.11 |

| Fengkai County Yide Chemical Co., Ltd | 30000tpa99.9%High concentrations of methylal plant | 1 | 2010.12 |

| Shandong Shengtong Bloc Co. Ltd. |

100000tpa formaldehyde plant High concentrations of methylal plant |

2 | 2011.1 |

| Longkou Haili Chemical Plant |

30000tpa formaldehyde plant 10000tpa methylal plant |

2 | 2011.4 |

| Jiangsu Sanmu Bloc Co. Ltd. | 50000tpa 99.5%High concentrations of methylal plant | 1 | 2011.4 |

| Kunming Jingao Chemical Co. Ltd. | 10000tpa methylal plant | 1 | 2011.5 |

| Wenan County Lilong Chemical Plant | 30000Tpa formaldehyde plant | 1 | 2011.6 |

| Shandong Dianshang Chemical Plant | 100000Tpa formaldehyde plant | 1 | 2011.6 |

| Maoming City Zhongguang Chemical Co., Ltd |

60000Tpa formaldehyde plant 30000tpa High concentrations of methylal plant |

2 | 2011.6 |

| Hebei Jingtaida Chemical Co., Ltd | 100000tpa methylal plant | 1 | 2011.10 |

| Shandong Chenxin New Energy Co. Ltd. | 10000tpa methylal plant | 1 | 2011.11 |

| Ninxia Xinao Chemical Co., Ltd | 20000tpa methylal plant | 1 | 2011.11 |

| Wenan County Pacific Chemical Co., Ltd |

80000tpa formaldehyde plant; 60000tpa methylal plant |

2 | 2012.07 |

| Shandong Chenxin New Energy Co. Ltd. | 10000tpa methylal plant | 1 | 2012.09 |

| Guangdong Maoming City Zhongguang Chemical Co., Ltd | 80000High concentrations of methylal plant | 1 | 2013.01 |

| Guangdong Maoming City Zhongguang Chemical Co., Ltd | 60000tpa formaldehyde plant | 1 | 2013.01 |

| Xianyang Hongyuan Chemical Co., Ltd | 60000tpa formaldehyde plant and 60000tpa High concentrations of methylal plant | 2 | 2013.02 |

| Jilin Sengong Chemical Co., Ltd |

50000tpa 55%formaldehyde plant tpa 55%formaldehyde plant 30000tpa High concentrations of methylal plant |

2 | 2013.12 |

| Chengdu Tianfeng SSTPC | 20000tpa High concentrations of methylal plant | 1 | 2014.01 |

| Shandong Yiyuan SSTPC | 15000tpa High concentrations of methylal plant | 1 | 2014.06 |

| Xinjiang Hengyang Chemical Co., Ltd | 100000tpa formaldehyde plant and 50000tpa methylal plant | 2 | 2014.06 |

Overview - 99.5% Concentration Process

Owing to the azeotrope from methylal , formaldehyde and water, adopting the normal rectification method cannot get high concentration methylal. Kaimao company, on the base of the original process for normal concentration methylal , has successfully researched the high concentration methylal process, via many tests and technical designs, making methylal purity to reach 99.5%.

1.Concentration of 90% methylal preparing unit

This unit is the same technology with 85%-92% methylal process, and the only difference is that 3# Pressurized Tower top gas is used to heat the tower bottom liquid of 1# Reaction Tower.

2. Concentration of 99.5% methylal preparing unit

Methyal with concentration about 90% is pumped by the high pressure pump into 3# Pressurized Tower. The tower bottom reboiler is heated by steam, with the tower controlled in a certain pressure. The liquid withdrew from the tower bottom is 99.5% methylal. The gas from the tower top firstly comes into 2# condenser for condensation; the released heat is used as the heat source of 1# reaction tower. The condensed liquid comes into 2# Reflux Drum, and part of it will be back flowed to 3# Pressurized Tower, other parts will be put to 4# Recovery Tower.

3.Methanol recycling unit

Most part of the liquid in 2# Reflux Drum is methylal, with litter methanol. Part of this liquid will be sent to the 4# Recovery Tower. The tower bottom reboiler is heated by the steam. The liquid withdrew from the tower bottom is high purity methanol, which can be sent to Mixer for continuous reaction. Part of the gas phase from the tower top after condensation will be back flowed to 4# Recovery Tower, other parts will be sent to 1# Reflux Drum for the continuous rectification.

Technology feature:

Exclusively create the pressure adding rectification technology to make high concentration methylal , which is very technically and economically efficient.

pdf

Owing to the azeotrope from methylal , formaldehyde and water, adopting the normal rectification method cannot get high concentration methylal. Kaimao company, on the base of the original process for normal concentration methylal , has successfully researched the high concentration methylal process, via many tests and technical designs, making methylal purity to reach 99.5%.

1.Concentration of 90% methylal preparing unit

This unit is the same technology with 85%-92% methylal process, and the only difference is that 3# Pressurized Tower top gas is used to heat the tower bottom liquid of 1# Reaction Tower.

2. Concentration of 99.5% methylal preparing unit

Methyal with concentration about 90% is pumped by the high pressure pump into 3# Pressurized Tower. The tower bottom reboiler is heated by steam, with the tower controlled in a certain pressure. The liquid withdrew from the tower bottom is 99.5% methylal. The gas from the tower top firstly comes into 2# condenser for condensation; the released heat is used as the heat source of 1# reaction tower. The condensed liquid comes into 2# Reflux Drum, and part of it will be back flowed to 3# Pressurized Tower, other parts will be put to 4# Recovery Tower.

3.Methanol recycling unit

Most part of the liquid in 2# Reflux Drum is methylal, with litter methanol. Part of this liquid will be sent to the 4# Recovery Tower. The tower bottom reboiler is heated by the steam. The liquid withdrew from the tower bottom is high purity methanol, which can be sent to Mixer for continuous reaction. Part of the gas phase from the tower top after condensation will be back flowed to 4# Recovery Tower, other parts will be sent to 1# Reflux Drum for the continuous rectification.

Technology feature:

Exclusively create the pressure adding rectification technology to make high concentration methylal , which is very technically and economically efficient.

https://drive.google.com/file/d/1h_VGszjpCMYRtBsf3dlXBzsjOjUdSqpg/view?usp=sharing

Products

TOP

工艺流程图

工艺流程图