85-92 Concentration Process

Performance

Overview

Performance - 85%-92% Concentration Process

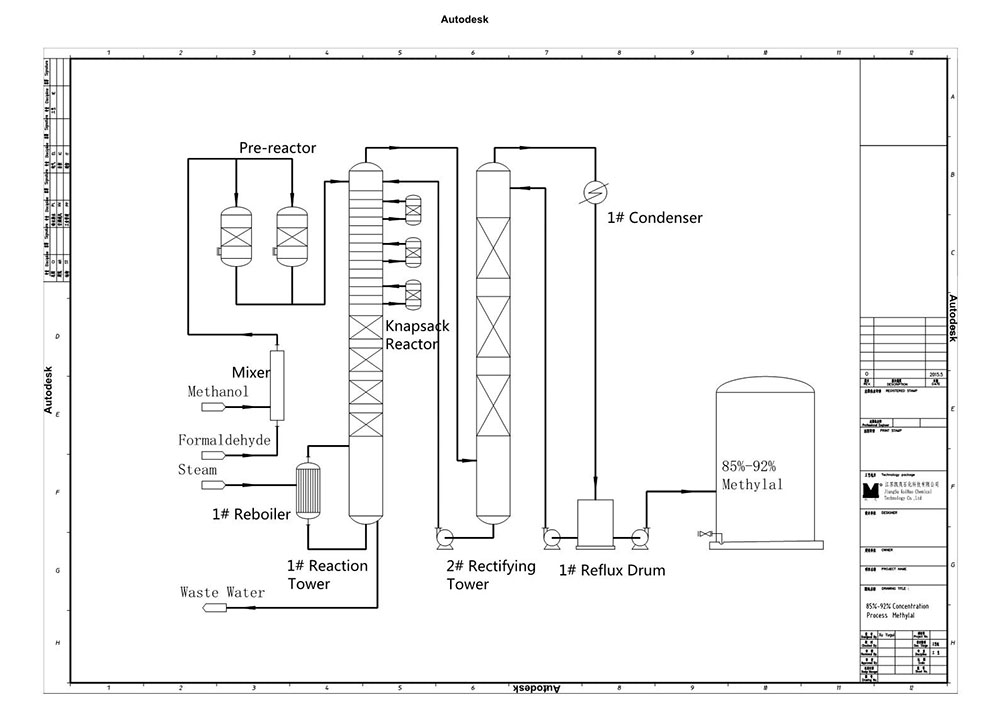

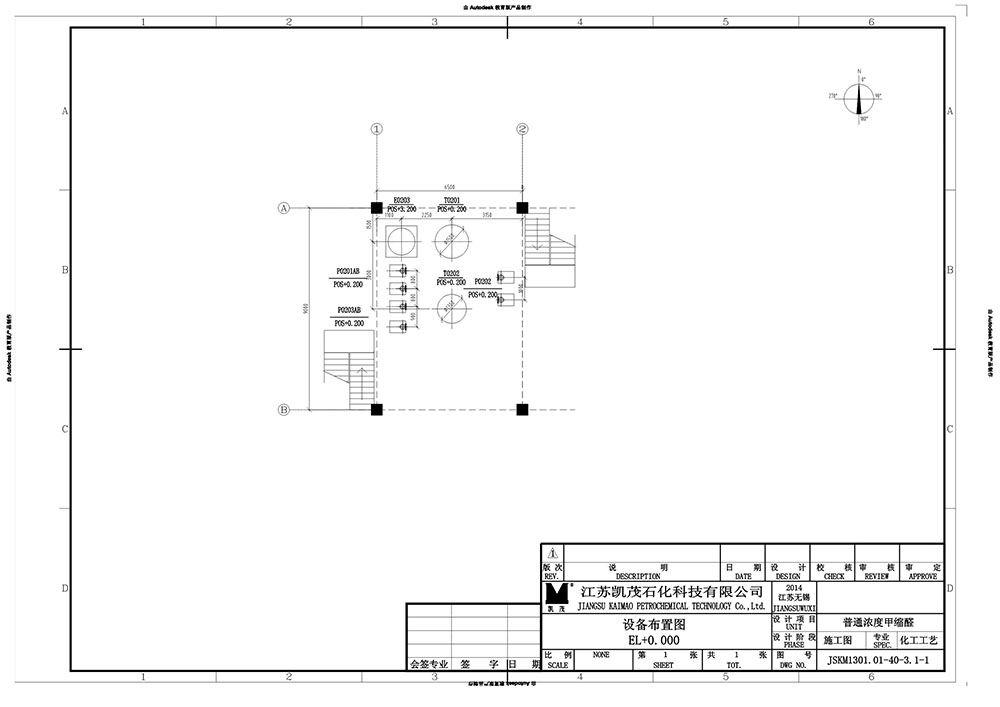

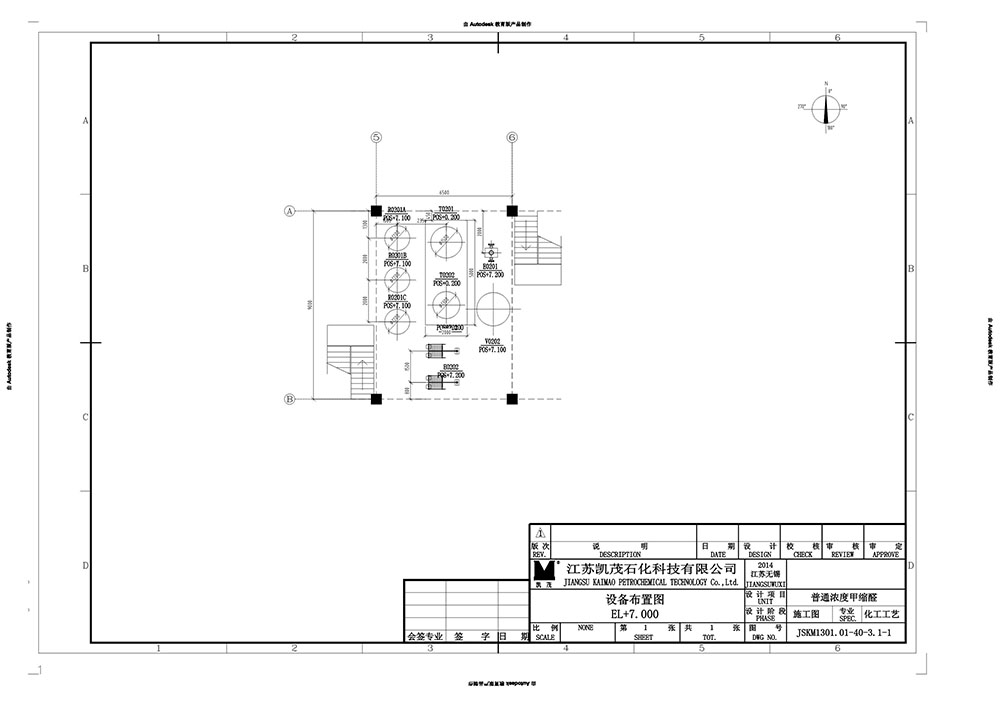

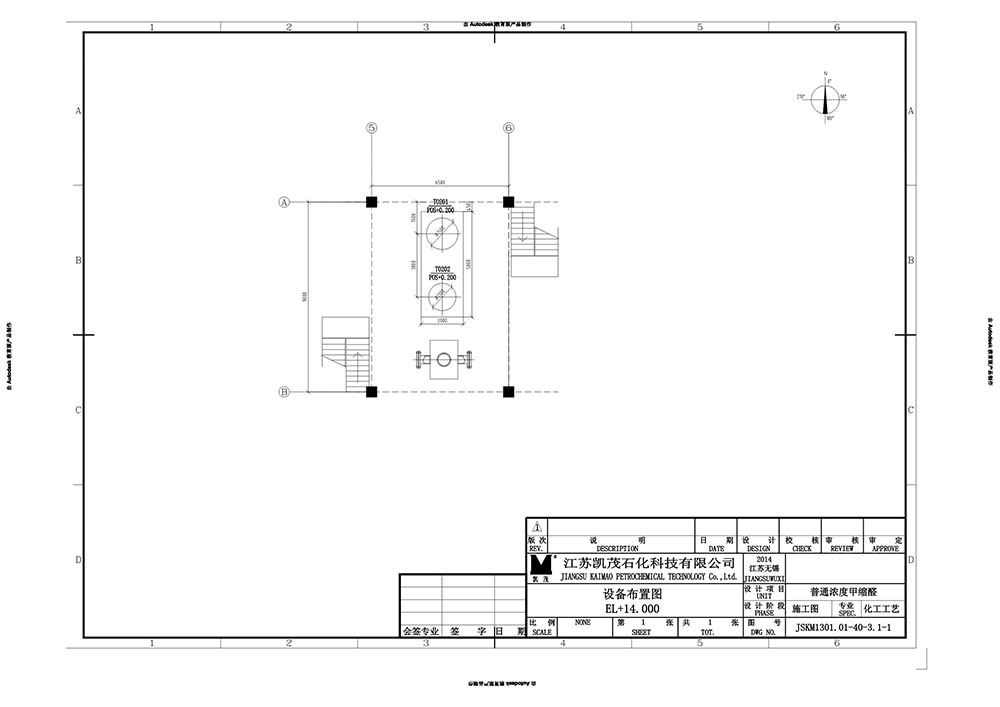

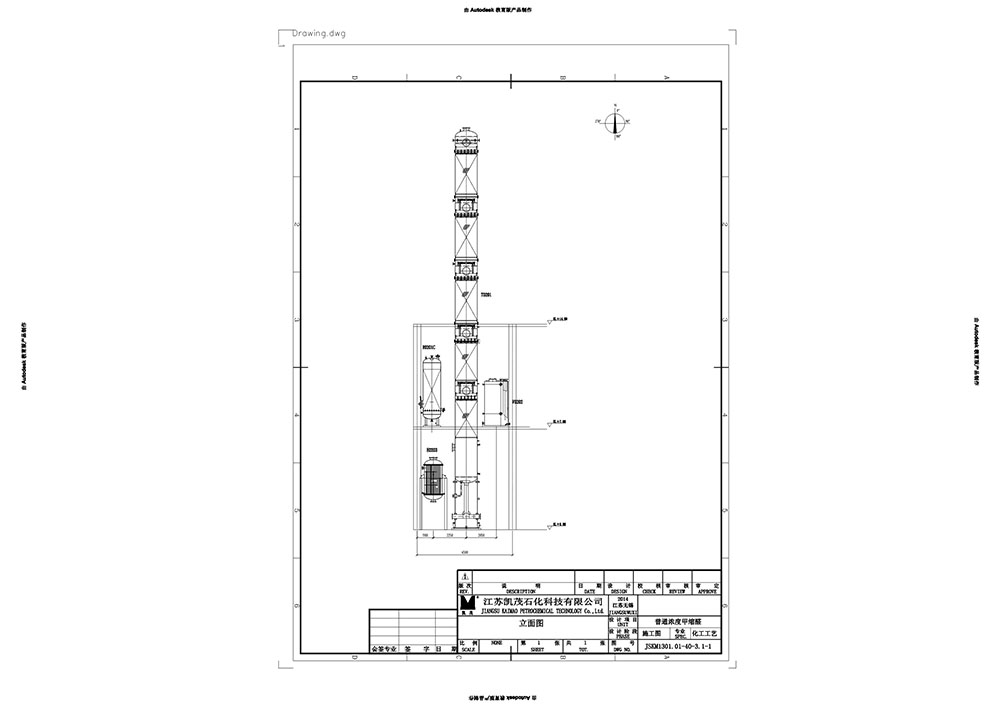

Process Digram&Layout Drawing

References

| No. | Item | Consumption quota | Remarks |

|---|---|---|---|

| 一 | Raw material and auxiliary material | ||

| 1 | Formaldehyde(37%) | 1.04T/T | |

| 2 | Methanol(99.5%) | 0.86T/T | |

| 二 | Utilities | ||

| 1 | Industrial feeding water t≤25℃ | Intermittent flushing | |

| 2 | Circulating water t≤32℃,△t=8℃ Circulating quantity per hour | 75 T/T | |

| 3 | Power(380V) | 50kWh/T | |

| 4 | Low pressure steamP=0.25 MPa(G) | 750kg/T |

| 工 程 名 称 | 型 号 及 参 数 | 生产线条数 | 完成日期 |

|---|---|---|---|

| 浙江豪博化工有限公司 |

75kt /a甲醛全套非标设备和技术服务 30 kt /a甲缩醛成套工程非标设备和技术服务 |

1 | 2007.7 |

| 浙江广天化工有限公司 |

50 kt /a甲醛全套工程项目 30 kt /a甲缩醛成套工程设备和技术服务 |

2 | 2007.12 |

| 福建省银泰有机化工有限公司 |

50kt /a甲醛全套非标设备和技术服务 20kt /a甲缩醛全套设备和技术服务 |

2 | 2009.8 |

| 天丰石化有限公司 | 20kt/a 甲缩醛总承包项目和技术服务 | 1 | 2010.3 |

| 鲁清防水建材有限公司 |

30kt/a 甲缩醛全套非标设备和技术服务 50kt/a 甲醛全套非标设备和技术服务 |

2 | 2010.4 |

| 安徽省福泰精细化工有限责任公司 | 30kt/a 甲缩醛全套非标设备和技术服务 | 1 | 2010.4 |

| 寿光市鲁清防水建材有限公司 | 20 kt/a 甲缩醛全套非标设备和技术服务 | 1 | 2010.7 |

| 梅河口市创源化工有限公司 | 30 kt/a 甲缩醛全套非标设备和技术服务 | 1 | 2010.11 |

| 巴州恒亚石油精细化工有限公司 |

80 kt/a 甲醛专有设备和技术服务 50 kt/a 甲缩醛专有设备和技术服务 |

2 | 2011.3 |

| 昌吉州锐源通化工有限责任公司 | 30 kt/a 甲缩醛专有设备和技术服务 | 1 | 2011.3 |

| 龙岩连润化工有限公司 | 30 kt/a 甲缩醛专有设备和技术服务 | 1 | 2011.6 |

| 哈尔滨巨业化工有限公司 | 50 kt/a 甲缩醛专有设备和技术服务 | 1 | 2011.7 |

| 河北邯郸龙港化工有限公司 | 5万吨/年甲缩醛项目专有设备和技术服务 | 1 | 2011.12 |

| 河北宇航化工有限公司 | 120kt /a甲缩醛总包工程 | 1 | 2012.05 |

| 淄博齐星化学科技有限公司 |

5万吨55%甲醛装置, 5万吨甲缩醛预留3万吨高浓度装置 |

2 | 2014.06 |

Methylal, chemical formula:

Overview - 85%-92% Concentration Process

Methylal is the transparent and colorless liquid with slight order, low boiling point and good solubility. Methylal is not only chemical material that can be widely used, but also it can be mixed with several reagents and good solubility.

In the last several years, chemistry industry has developed rapidly, the application area of methylal has extend from the original specific reagents to several fields, such as cosmetic ,medicine ,household goods ,industrial auto supplies, pesticides, Leather polishing cleaner and rubber industry. Methylal has good degreasing ability and volatility, which can be used as cleanser, replacing F11 and F113 and chlorinated solvent, be widely used in paint and ink, and decrease the organic discharging and the air pollution. As the intermediate for pesticide compound, methylal is widely used in pesticide industry. As material for compound resin, methylal is widely used in the production of POM.

Sulfuric acid process is continued in the production technology of methylal manufacturing, with serious corrosion to the equipment. Japan has developed the new technology by catalytic rectification process to compound methylal, to solve the disadvantages of the old process and match with the methylal plant. Using solid resin as catalyst has basically solved the problem of equipment corrosion, and deeply improves the product quantity and quality. Shangdong Yantai University has successfully researched the combined technology of solid catalyst reaction and rectification, on the base of Japanese technology. To solve the problem of catalyst regeneration difficulties, Kaimao Company has developed the plug-in reactor technology on the base of combined technology of reaction and rectification, extending the catalyst service life and improving capacity. At the same time, Hengmao Company has made several other researches, and owns several methylal technology patents.

Methanol and formaldehyde has condensation reaction to form methylal, with equation as below,

2CH3OH+CH2O = CH3OCH2OCH3+H2O

To separately pump industrial methanol and formaldehyde solution with a proportion into fixed bed media reactor ,and control the reaction temperature between 40℃~65℃, having liquid phase reaction to make mixing liquid of methylal, methanol and water, then it will be normal pressure rectification tower for separation. The rectification tower heater uses steam as heating media. The azeotrope of methylal and methanol is discharged from top of rectification tower, and the gas, after all get condensed, will be sent to the intermediate storage tank.

Owing to the azeotrope of methylal, methanol and water, adopting the normal rectification can get no high purity methylal. Kaimao Company,on the base on the normal concentration methylal technology, has successfully researched the high concentration methylal technology, after many tests and technical design, which can improve the methylal purity to be 99.5%.

Brief Introduction of the 85%-92% methylal Process:

1. The mixing and pre-reaction unit

Start formaldehyde pump and methanol pump, and put formaldehyde and methanol into mixer with a certain quality proportion. After mixing, get it preheated and heat the mixing liquid into a certain temperature. Then, the mixing liquid will be sent into reactor for primary reaction.

2. Rectification reaction unit

Pre-reacting liquid comes into 1# Reaction Tower. The waste water from tower bottom can be used for preheating the mixture liquid of formaldehyde and methanol and then put into waste water pool. The gas phase from the tower top comes into 2# Rectifying Tower for rectification. The liquid from the tower bottom will be pumped into 1# Reaction Tower. The gas from the tower top via condenser comes into back flowing tank. Part of it will be back flow to the tower top, others will be withdrew to the tank yard, getting 85-92% product of methylal

To further derease the COD content of the waste water, Kaimao technical Team has researched Knapsack Process. In the engineering reality, this process is good in decreasing the COD content.

Technical Characteristic:

1. By adopting Kaimao’s technology in methylal rectification reaction, the tower bottom of the reactor is with low COD content in waste water.

2. Methanol and formaldehyde consumption is low in the process.

pdf

Overview - 85%-92% Concentration Process

Methylal is the transparent and colorless liquid with slight order, low boiling point and good solubility. Methylal is not only chemical material that can be widely used, but also it can be mixed with several reagents and good solubility.

In the last several years, chemistry industry has developed rapidly, the application area of methylal has extend from the original specific reagents to several fields, such as cosmetic ,medicine ,household goods ,industrial auto supplies, pesticides, Leather polishing cleaner and rubber industry. Methylal has good degreasing ability and volatility, which can be used as cleanser, replacing F11 and F113 and chlorinated solvent, be widely used in paint and ink, and decrease the organic discharging and the air pollution. As the intermediate for pesticide compound, methylal is widely used in pesticide industry. As material for compound resin, methylal is widely used in the production of POM.

Sulfuric acid process is continued in the production technology of methylal manufacturing, with serious corrosion to the equipment. Japan has developed the new technology by catalytic rectification process to compound methylal, to solve the disadvantages of the old process and match with the methylal plant. Using solid resin as catalyst has basically solved the problem of equipment corrosion, and deeply improves the product quantity and quality. Shangdong Yantai University has successfully researched the combined technology of solid catalyst reaction and rectification, on the base of Japanese technology. To solve the problem of catalyst regeneration difficulties, Kaimao Company has developed the plug-in reactor technology on the base of combined technology of reaction and rectification, extending the catalyst service life and improving capacity. At the same time, Hengmao Company has made several other researches, and owns several methylal technology patents.

Methanol and formaldehyde has condensation reaction to form methylal, with equation as below,

2CH3OH+CH2O = CH3OCH2OCH3+H2O

To separately pump industrial methanol and formaldehyde solution with a proportion into fixed bed media reactor ,and control the reaction temperature between 40℃~65℃, having liquid phase reaction to make mixing liquid of methylal, methanol and water, then it will be normal pressure rectification tower for separation. The rectification tower heater uses steam as heating media. The azeotrope of methylal and methanol is discharged from top of rectification tower, and the gas, after all get condensed, will be sent to the intermediate storage tank.

Owing to the azeotrope of methylal, methanol and water, adopting the normal rectification can get no high purity methylal. Kaimao Company,on the base on the normal concentration methylal technology, has successfully researched the high concentration methylal technology, after many tests and technical design, which can improve the methylal purity to be 99.5%.

Brief Introduction of the 85%-92% methylal Process:

1. The mixing and pre-reaction unit

Start formaldehyde pump and methanol pump, and put formaldehyde and methanol into mixer with a certain quality proportion. After mixing, get it preheated and heat the mixing liquid into a certain temperature. Then, the mixing liquid will be sent into reactor for primary reaction.

2. Rectification reaction unit

Pre-reacting liquid comes into 1# Reaction Tower. The waste water from tower bottom can be used for preheating the mixture liquid of formaldehyde and methanol and then put into waste water pool. The gas phase from the tower top comes into 2# Rectifying Tower for rectification. The liquid from the tower bottom will be pumped into 1# Reaction Tower. The gas from the tower top via condenser comes into back flowing tank. Part of it will be back flow to the tower top, others will be withdrew to the tank yard, getting 85-92% product of methylal

To further derease the COD content of the waste water, Kaimao technical Team has researched Knapsack Process. In the engineering reality, this process is good in decreasing the COD content.

Technical Characteristic:

1. By adopting Kaimao’s technology in methylal rectification reaction, the tower bottom of the reactor is with low COD content in waste water.

2. Methanol and formaldehyde consumption is low in the process.

https://drive.google.com/file/d/1P14S63HQTrRlLrHgpCaAB8VMILLRjVVe/view?usp=sharing

Products

TOP