Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

-

Steel Wire Reinforced (Twisted) Pipe Production line

The special construct of three lays and steel wire can be adapted to dirrerent pressures by regulating the paramenters of the middle layer. Temperature for using is below +40 and the pressure is 1.0-3.5Mpa. performances: antistatic, fireproofing, wear-resistant,pressure-resistant,light,tough

-

PMMA Coated Lenses Sheet Production Line

Application: Widely used in instruments, instrument parts, trains, planes, elevators, mirror. Electronic products: TV、computer screen. Technology products: specimens, labels, bank counter, supermarket, stationery and any other articles for daily use. Pr

- Contacter: Mrs. Tang

- Tel: 86-18068054180

- Fax:

- Email: chloe@neotek.cn

-

Company Address:

No. 99, Shaojing Road, Kunshan Economic & Technlogy Development Zone, Kunshan City, Jiangsu Province, China

Steel Wire Reinforced (Twisted) Pipe Production line

The special construct of three lays and steel wire can

be adapted to dirrerent pressures by regulating the paramenters of the middle

layer. Temperature for using is below +40 and the pressure is 1.0-3.5Mpa.

performances: antistatic, fireproofing,

wear-resistant,pressure-resistant,light,tough

Steel Wire Reinforced (Twisted) Pipe Production line

The special construct of three lays and steel wire can

be adapted to dirrerent pressures by regulating the paramenters of the middle

layer. Temperature for using is below +40 and the pressure is 1.0-3.5Mpa.

performances: antistatic, fireproofing,

wear-resistant,pressure-resistant,light,tough

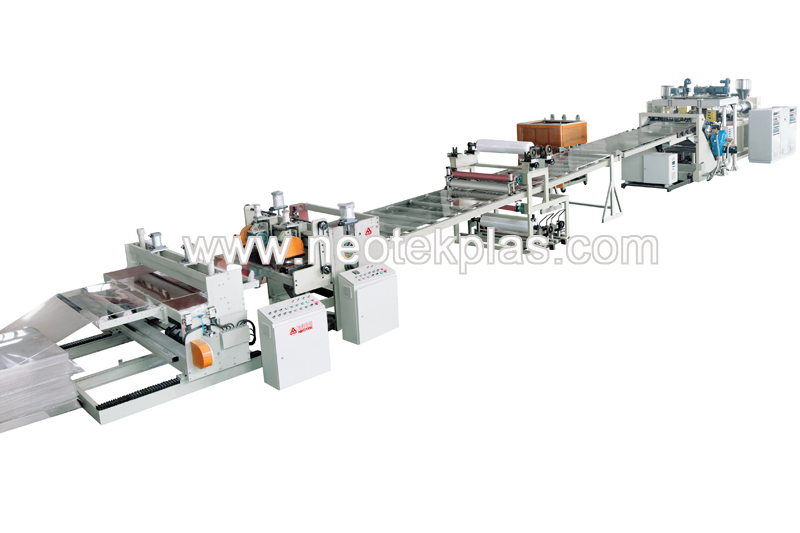

PMMA Coated Lenses Sheet Production Line

Application:

Widely used in instruments, instrument parts, trains, planes, elevators,

mirror. Electronic products: TV、computer

screen.

Technology

products: specimens, labels,

bank counter, supermarket, stationery and any other articles for daily use.

Processing

rang:

Thickness: 0.8-10mm Width: 800-2000mm

PMMA Coated Lenses Sheet Production Line

Application:

Widely used in instruments, instrument parts, trains, planes, elevators,

mirror. Electronic products: TV、computer

screen.

Technology

products: specimens, labels,

bank counter, supermarket, stationery and any other articles for daily use.

Processing

rang:

Thickness: 0.8-10mm Width: 800-2000mm

PC, PMMA, PS, MS Board Extrusion Line

Characteristic:

The transmission of light: good pervious to light performance, ageing resistance

Weather resistance: UV co-extrusion processing, can resist UV damage

Impact resistance, impact strength is common glass of 250 to 300 times

Flame retardant: national test belongs to the B1 level, no fire, no poison

Temperature tolerance: PC board in the range of 40 degrees below zero to 120 degree does not affect the plate quality, stable physical properties

Portability: light weight in handling and installation, can cold bending , hot forming

Good sound insulation: sound insulation effect, is the first selection of highway noise barrier materials both at home and broad

Processing range: the maximum wide 2 m, thickness range 1.5-15 mm

PC, PMMA, PS, MS Board Extrusion Line

Characteristic:

The transmission of light: good pervious to light performance, ageing resistance

Weather resistance: UV co-extrusion processing, can resist UV damage

Impact resistance, impact strength is common glass of 250 to 300 times

Flame retardant: national test belongs to the B1 level, no fire, no poison

Temperature tolerance: PC board in the range of 40 degrees below zero to 120 degree does not affect the plate quality, stable physical properties

Portability: light weight in handling and installation, can cold bending , hot forming

Good sound insulation: sound insulation effect, is the first selection of highway noise barrier materials both at home and broad

Processing range: the maximum wide 2 m, thickness range 1.5-15 mm

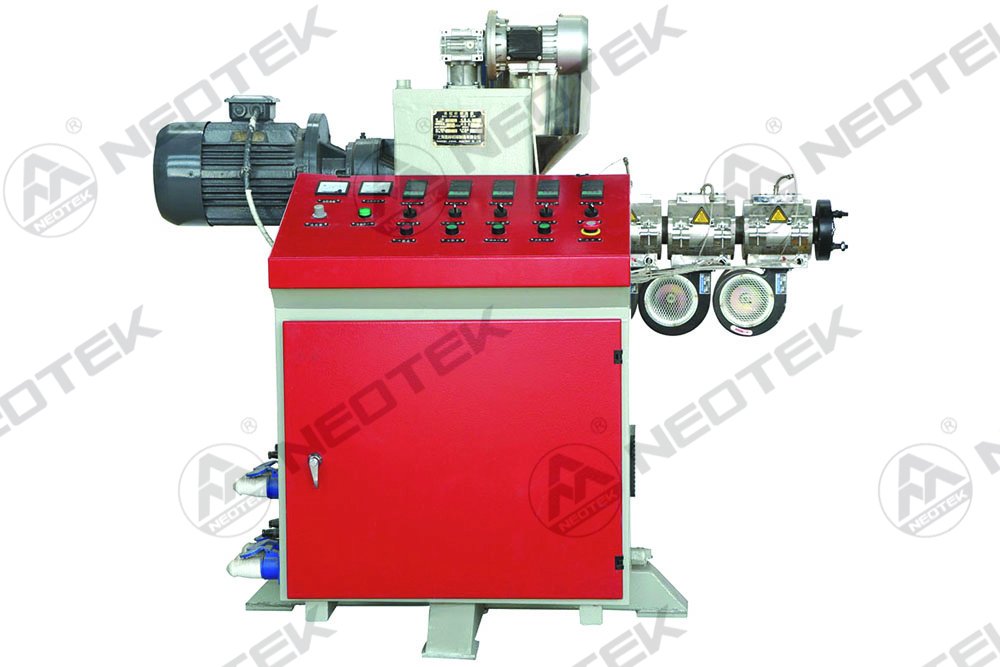

Small Co-Extruder

For marking line, surface co-extrusion, normally we use small co-extruder.

Model

ZJ20/20

ZJ25/20

ZJ30/25

ZJ35/25

ZJ45/25

ZJ50/25

Power of drive(kw)

0.55

2.2

3

5.5

7.5

7.5

11

Screw diameter

20

25

30

35

45

50

L/D ratio

20

20

25

25

25

25

Screw material

& productivity

(kg/h)

PE, PP

1

4

PVC

8

12

18

22

25

PMMA, ASA

10

15

20

22

Small Co-Extruder

For marking line, surface co-extrusion, normally we use small co-extruder.

Model

ZJ20/20

ZJ25/20

ZJ30/25

ZJ35/25

ZJ45/25

ZJ50/25

Power of drive(kw)

0.55

2.2

3

5.5

7.5

7.5

11

Screw diameter

20

25

30

35

45

50

L/D ratio

20

20

25

25

25

25

Screw material

& productivity

(kg/h)

PE, PP

1

4

PVC

8

12

18

22

25

PMMA, ASA

10

15

20

22

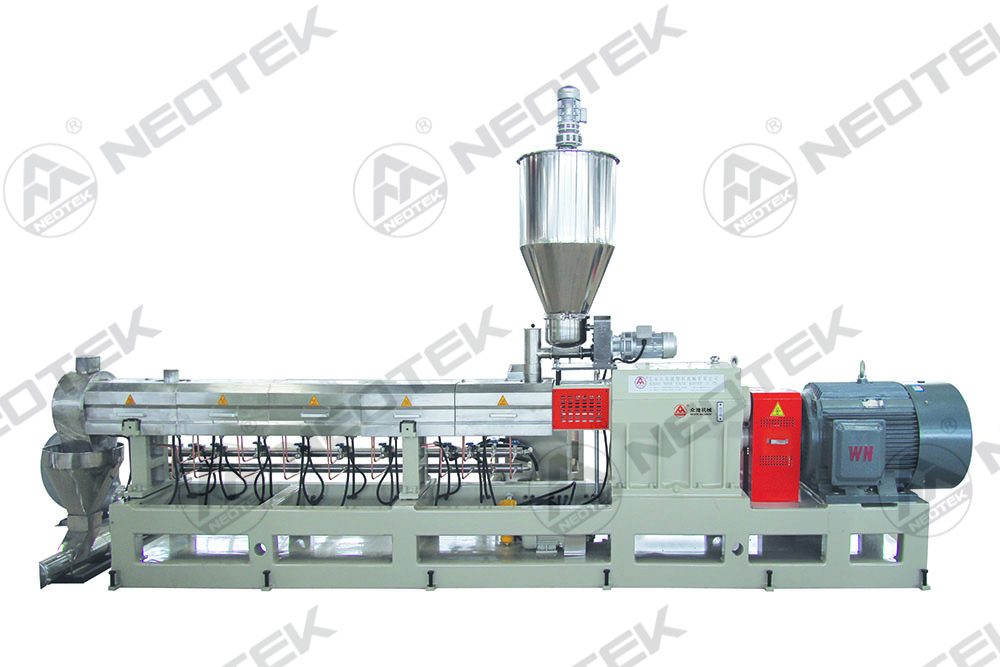

Parallel twin screw extruder

SJP parallel twin screw extruder is applicant for PVC powder material, with different mould and downstream equipment, it can produce pipe, profile, plate&sheet and pelletizing.

Model

SJP75

SJP90

SJP110

SJP120

SJP130

Driving power, kw

45

55

75

110

132

Screw diameter, mm

75

90

110

120

130

L/D

26-36

26-36

26-36

26-36

26-36

Screw rotation speed, rpm

45

45

45

45

45

PVC output capacity, kg/h

220-350

280-460

350-650

500-800

680-1000

Parallel twin screw extruder

SJP parallel twin screw extruder is applicant for PVC powder material, with different mould and downstream equipment, it can produce pipe, profile, plate&sheet and pelletizing.

Model

SJP75

SJP90

SJP110

SJP120

SJP130

Driving power, kw

45

55

75

110

132

Screw diameter, mm

75

90

110

120

130

L/D

26-36

26-36

26-36

26-36

26-36

Screw rotation speed, rpm

45

45

45

45

45

PVC output capacity, kg/h

220-350

280-460

350-650

500-800

680-1000

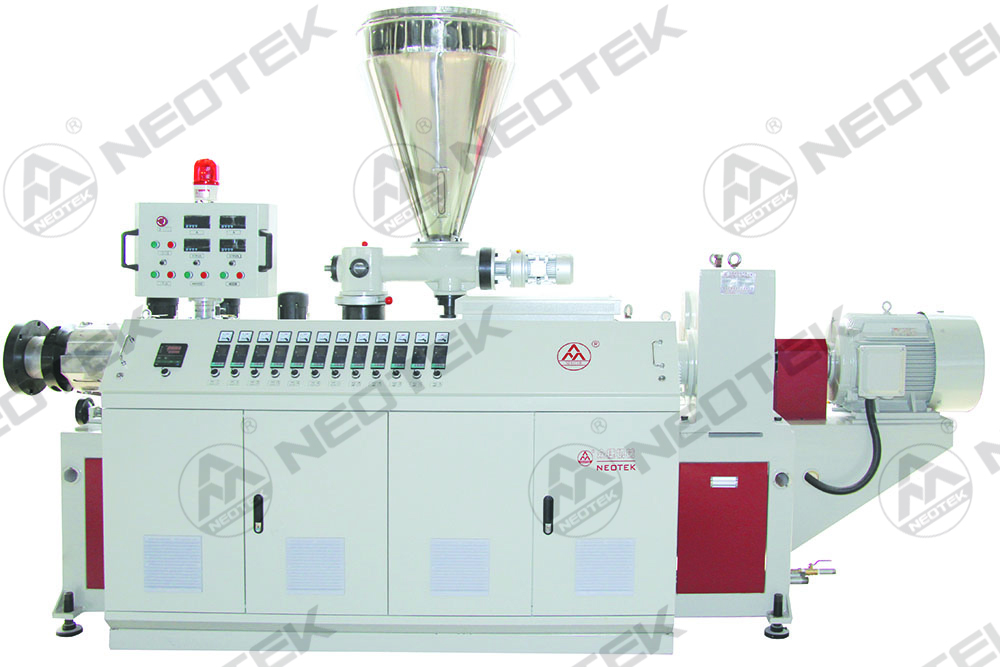

Conical twin screw extruder

SJZ Conical Twin screw extruder is application for PVC powder material, with different mould and downstream equipment, it can produce pipe, profile, plate & sheet, and pelletizing

For pipe application

Model

SJZ45/90

SJZ50/105

SJZ55/110

SJZ65/132

SJZ80/156

SJZ92/188

Motor power

15

18.5

22

37

55

110

Screw diameter

45/90

51/105

55/110

65/132

80/156

92/188

Screw rotation speed

45

45

45

45

34.7

34.7

Output capacity(PVC)

100

120

150

250

450

800

For PVC & WPC profile application

Model

SJZ45/90

SJZ50/105

SJZ55/110

SJZ65/132

SJZ80/156

SJZ92/188

Motor power

15

18.5

22

30-37

55

110-132

Screw diameter

45/90

51/105

55/110

65/132

80/156

92/188

Screw rotation speed

34.7

34.7

34.7

34.7

34.7

34.7

Output capacity(PVC)

60-80

80-100

120

150-250

250-400

500-700

Conical twin screw extruder

SJZ Conical Twin screw extruder is application for PVC powder material, with different mould and downstream equipment, it can produce pipe, profile, plate & sheet, and pelletizing

For pipe application

Model

SJZ45/90

SJZ50/105

SJZ55/110

SJZ65/132

SJZ80/156

SJZ92/188

Motor power

15

18.5

22

37

55

110

Screw diameter

45/90

51/105

55/110

65/132

80/156

92/188

Screw rotation speed

45

45

45

45

34.7

34.7

Output capacity(PVC)

100

120

150

250

450

800

For PVC & WPC profile application

Model

SJZ45/90

SJZ50/105

SJZ55/110

SJZ65/132

SJZ80/156

SJZ92/188

Motor power

15

18.5

22

30-37

55

110-132

Screw diameter

45/90

51/105

55/110

65/132

80/156

92/188

Screw rotation speed

34.7

34.7

34.7

34.7

34.7

34.7

Output capacity(PVC)

60-80

80-100

120

150-250

250-400

500-700

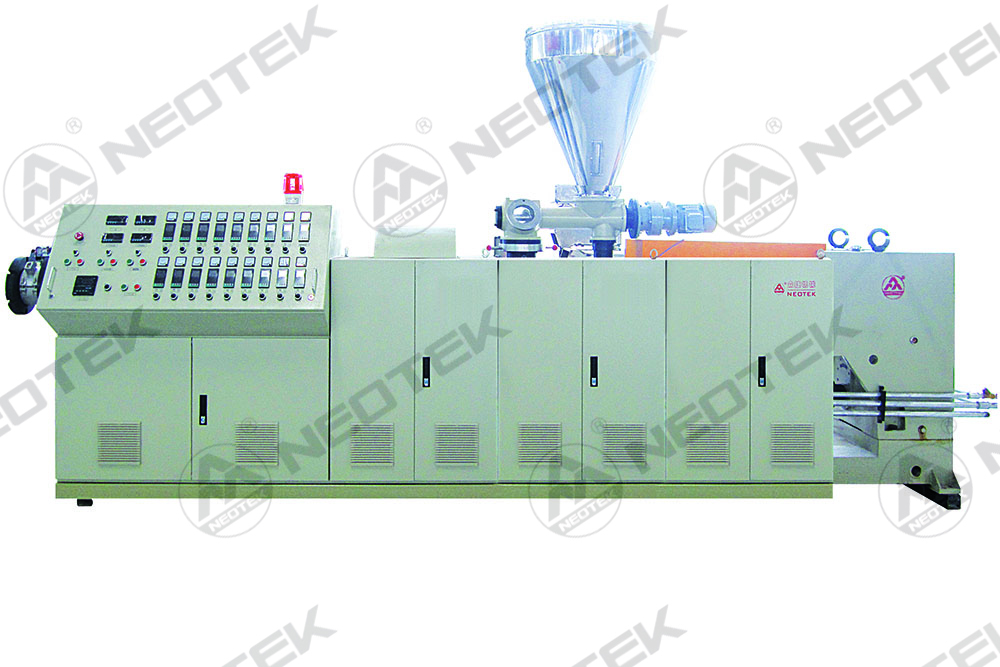

Single screw extruder

The single-screw extruder is developed by our company adopting latest advanced technology. Screw optimizes composing separate type screw and mixing parts. Barrel optimizes composing groove barrel and lengthened feeding segment. There is advantage as following by using separate type screw and groove barrel together:

1. It's optimized during material melting process. Thus get more extrusion throughput.

2. It is realized extruding melt material in low temperature.

3. Cutting function is caused through separate clearance and it makes material equal well.

4. It's controlled during melt plasticization process. Therefore only granule smaller than separate clearance can enter melt channel.

5. Wide manufacture range for different materials. It's suitable for all kind of polyolefin materials and specially for material for HDPE, PP, ABS pipe.

Single screw extruder

The single-screw extruder is developed by our company adopting latest advanced technology. Screw optimizes composing separate type screw and mixing parts. Barrel optimizes composing groove barrel and lengthened feeding segment. There is advantage as following by using separate type screw and groove barrel together:

1. It's optimized during material melting process. Thus get more extrusion throughput.

2. It is realized extruding melt material in low temperature.

3. Cutting function is caused through separate clearance and it makes material equal well.

4. It's controlled during melt plasticization process. Therefore only granule smaller than separate clearance can enter melt channel.

5. Wide manufacture range for different materials. It's suitable for all kind of polyolefin materials and specially for material for HDPE, PP, ABS pipe.