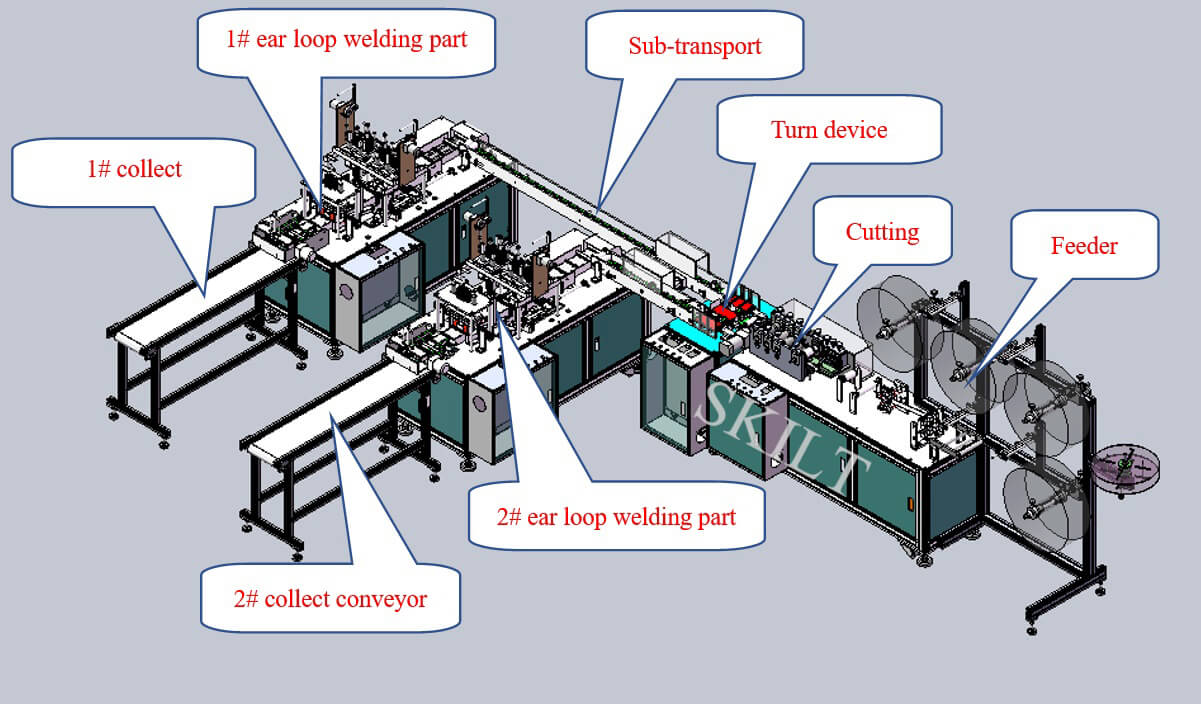

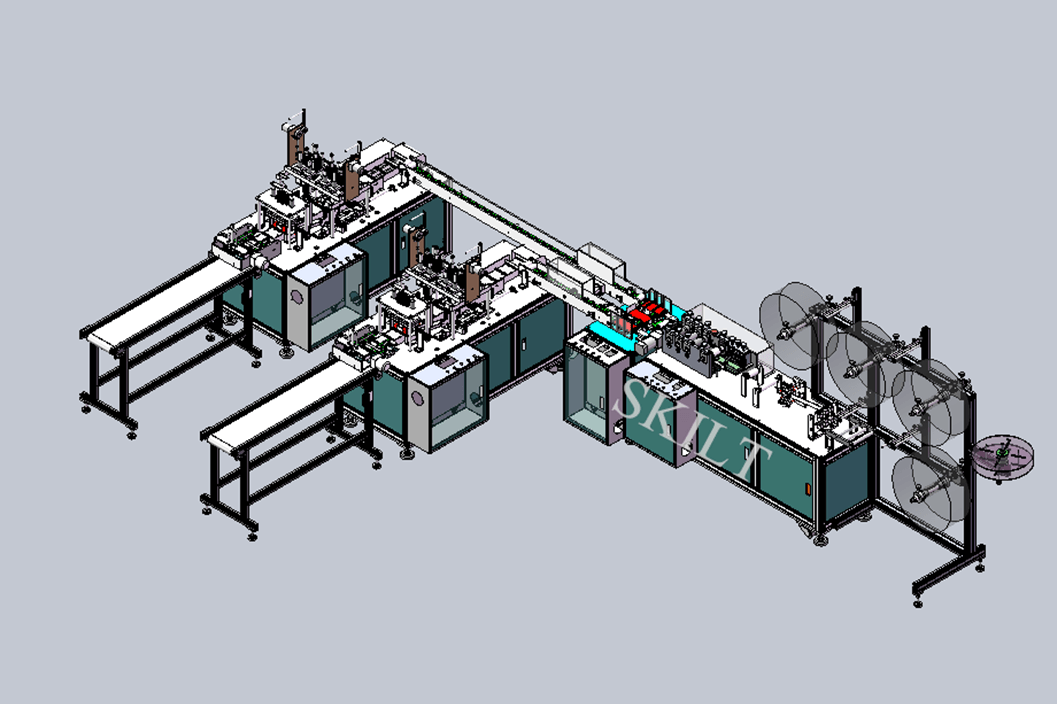

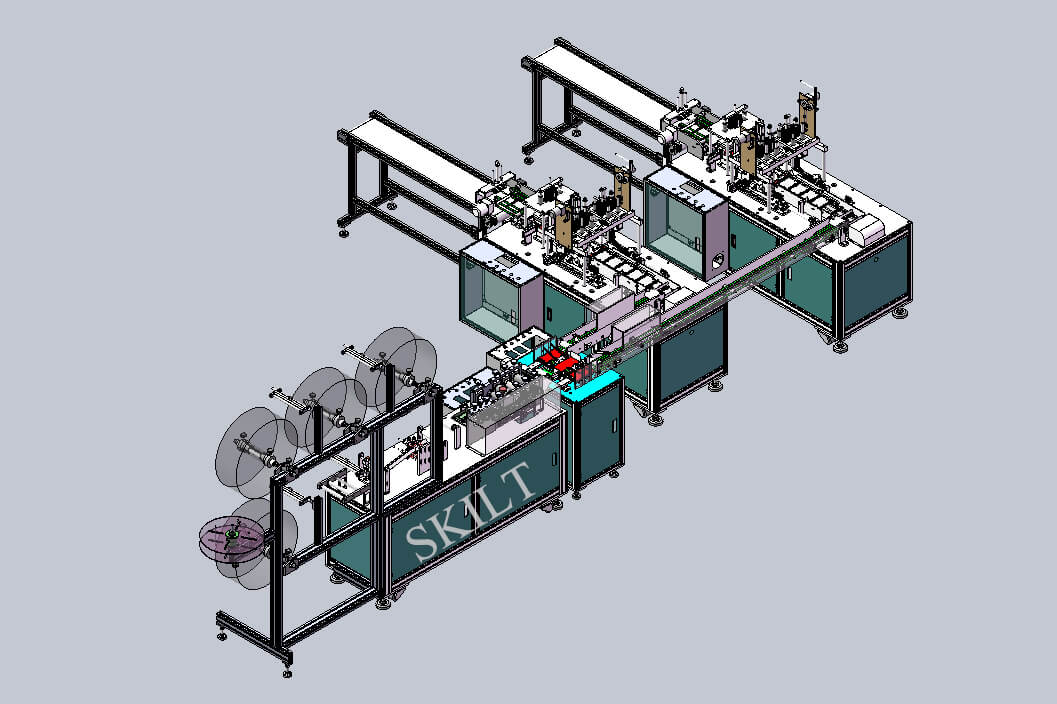

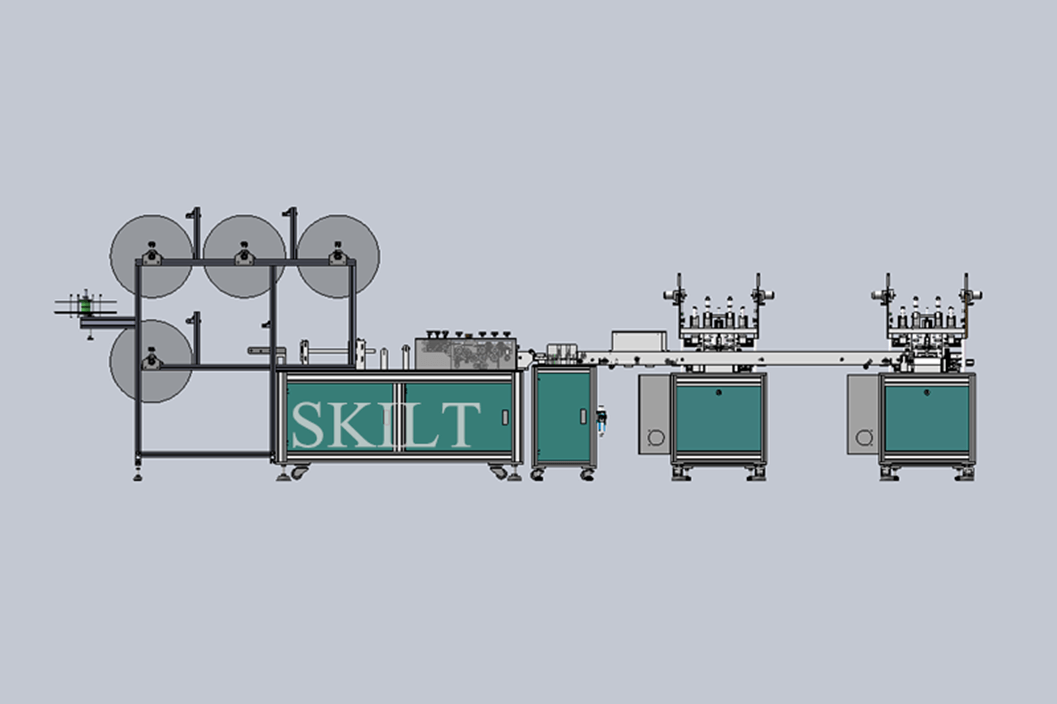

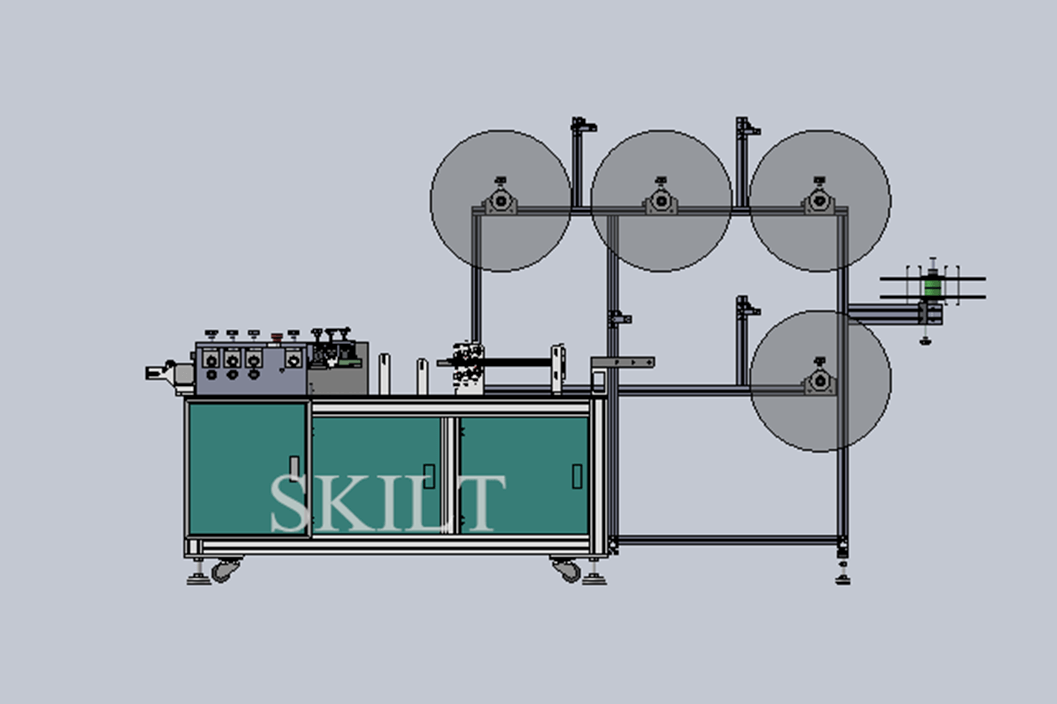

Equipment composition

-

Electrical cabinet,1 set flat non-woven feeding&cutting machine, 1 set mask delivery part ,2 sets ear loop welding equipment,Operation system and control system;

Electrical cabinet,1 set flat non-woven feeding&cutting machine, 1 set mask delivery part ,2 sets ear loop welding equipment,Operation system and control system;

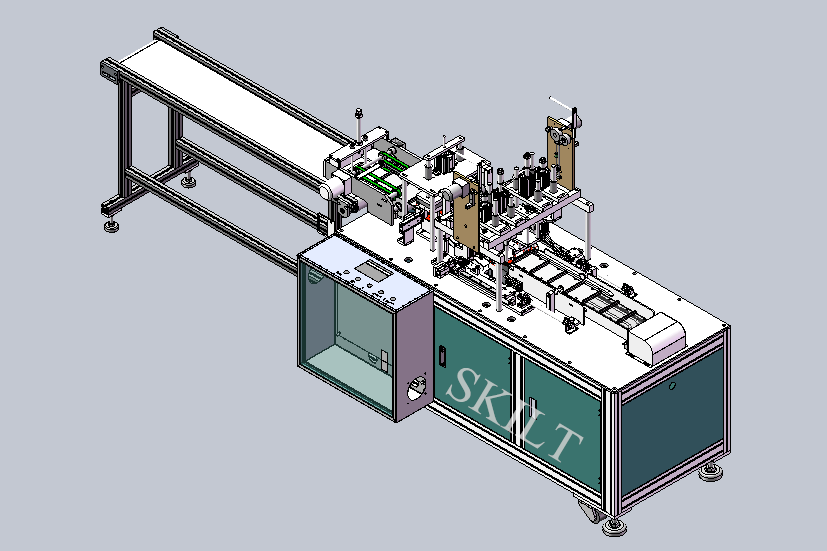

Control system: PLC control system; The mask body automatically transmitted to ear welding equipment, maximum limit artificial cost and with higher production capacity.

Operation system: Touch screen show Chinese and English two kinds language, rich with help function and fault display function ;

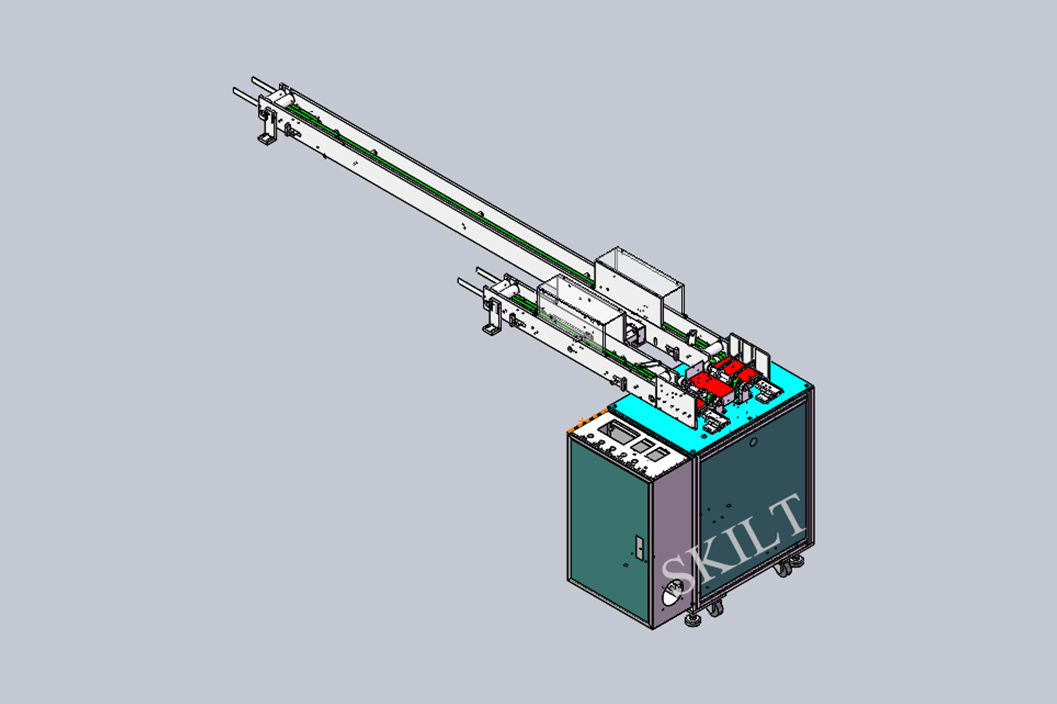

Send label system:Panisonic servo control system, stable with high speed;

Clean and hygienic : The equipment goes from raw material to finished product output,automatic operation, reduce human touch masks in the production process, meet the industry testing standards;

Once non woven raw material in unwinding part use up , machine stop automatically .

Worker feeder the non-woven→ ear loop automatic feeding→ Ultrasonic Ear loop Welding→ now-woven side part feeding and hemming→Ultrasonic non-woven side part welding→ non-woven side cutting→ mask delivery out → count → Mask Stacked → conveyor collect and delivery out ;

|

No |

Name |

Model |

Unit |

Brand |

|

1 |

HMI (Touch screen) |

TG765S-XT |

4 sets |

XINJIE |

|

2 |

PLC 1 |

XD3-24R-E |

1 set |

XINJIE |

|

3 |

PLC 2 |

XD5-48T6-E |

1 set |

XINJIE |

|

4 |

PLC 3 |

XD3-60RT-E |

2 sets |

XINJIE |

|

5 |

PLC3- model |

XD-E16Y |

2 sets |

XINJIE |

|

6 |

Sensor |

GTE6-N1211 |

4 piece |

SICK |

|

7 |

Trough photoelectric sensor |

EE-SX950-W |

3 piece |

OMRON |

|

8 |

750W Servo motor |

MHMF082L1U2M |

2 sets |

Panisonic |

|

9 |

750W Diver |

MCDLN35S |

2 sets |

Panisonic |

|

10 |

Inverter |

750W |

1 piece |

Delta |

|

11 |

Step motor |

2403HS40V8 |

2 sets |

|

|

12 |

Step motor |

2403HS40V8-2 |

2 sets |

|

|

13 |

cylinder |

|

48 piece |

AirTAC |

|

Model |

PTC-KZJ |

|

Driving Mode |

Servo motor |

|

Operation method |

HMI control system |

|

Mask size |

175mmx95mm |

|

Yield(pcs/min) |

90-110 pcs/min |

|

Suit for mask type |

Three-layer flat medical mask, surgical mask |

|

Applicable materials |

pp non-woven composite fiber |

|

Layers of cloth |

3 layers |

|

Composite approach |

Ultrasonic welding |

|

Demand pressure |

0.6Mpa |

|

Voltage (can customized) |

110V/220V/380V |

|

Air source |

0.5-0.8MPa, flow rate is about 350L / min |

|

Operating environment |

Temperature 10 ~ 35 ℃, |

|

Power(Kw) |

10KW |

|

Weight(kg) |

1800 |

|

Machine size |

6200*3500*2000mm |