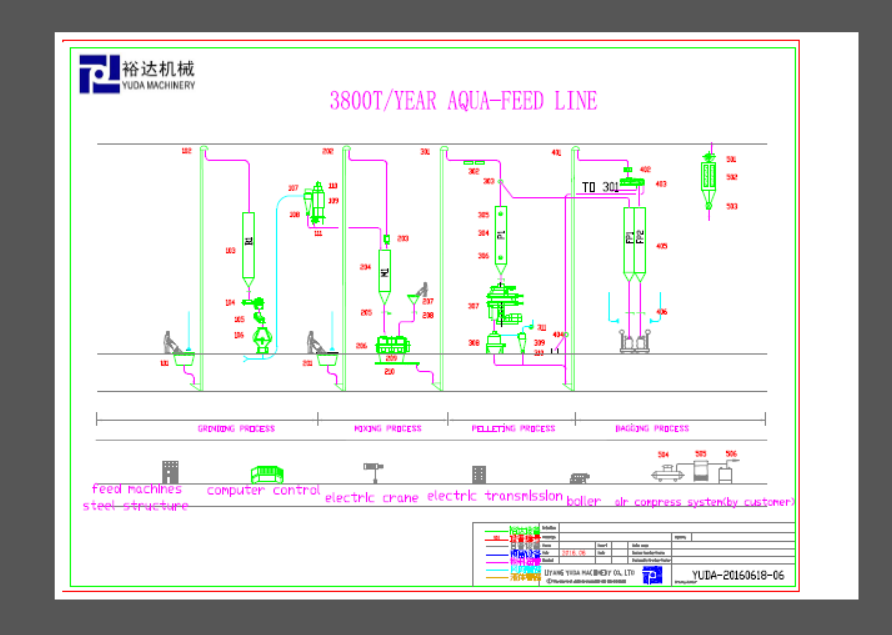

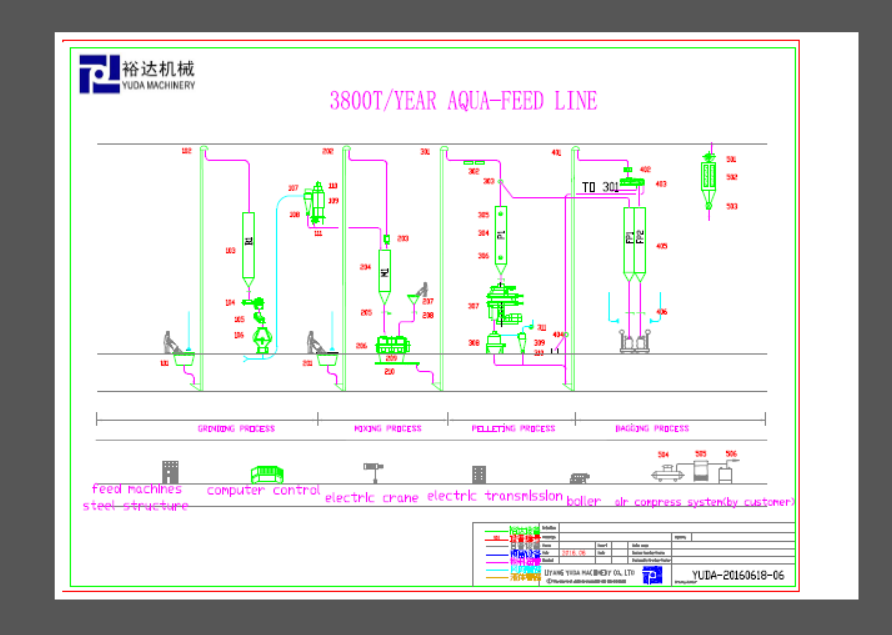

3800TY Aqua-feed Line

Design Flow Chart

Project Machine List

Project Machine List

Electric Control

| 3800T/YEAR AQUA-FEED LINE | ||||||

|---|---|---|---|---|---|---|

| Serial | Name | Model | Quantity | Power(KW) | Note | |

| single | total | |||||

| 1、pulverizing process | ||||||

| 101 | discharging pit、grizzly |

|

1 |

|

|

|

| 102 | elevator | TDTG36/18 | 1 | 1.50 | 1.50 | Non-return means four sides engaging process, rigidity |

| 103 | pulverizing-pending silo | 1cbm | 1 |

|

|

|

| 104 | Feeding cleaning sieve | TWCZ18 | 1 | 1.10 | 1.10 | Speed Control |

| 105 | magnetic plate |

|

1 |

|

|

Stainless steel, high magnetic |

| 106 | broad hanmer mill | SFSP65×38 | 1 | 37.0 | 37.00 | Hammer milling, uniform particle size distribution Φ1.2 sieve |

| 107 | cyclone | air locker | 1 |

|

|

|

| 108 | air locker | GFZ9 | 1 | 0.75 | 0.75 |

|

| 109 | simple pulse dust collector | TBLMY26-2000 | 1 |

|

|

Innovative and efficient dust removal equipment |

| 110 | high pressure fan | 9-26NO4.5A | 1 | 7.50 | 7.50 |

|

| 111 | air locker | GFZ5 | 1 | 0.55 | 0.55 |

|

|

|

subtotal |

|

|

|

48.40 |

|

| 2、Mixing process | ||||||

| 201 | discharging pit、grizzly |

|

1 |

|

|

|

| 202 | elevator | TDTG36/18 | 1 | 1.50 | 1.50 | Non-return means four sides engaging process, rigidity |

| 203 | Permanent magnet cylinder | TCXT20 | 1 |

|

|

|

| 204 | mixing-pending silo | 1cbm | 1 |

|

|

|

| 205 | pneumatic valve | TZMQ40×40 | 1 |

|

|

|

| 206 | screw mixer | SLHY.1 | 1 | 11.00 | 11.00 | Mechanical equipment through the National Fisheries Quality Supervision and Inspection Center, mixing soft, short, high uniformity. Small electric door |

| 207 | small material adding hopper |

|

1 |

|

|

|

| 208 | pneumatic valve | TZMQ25×25 | 1 |

|

|

|

| 209 | buffer silo |

|

1 |

|

|

|

| 210 | screw conveyor | TLSS20 | 1 | 2.20 | 2.20 |

|

|

|

subtotal |

|

|

|

14.70 |

|

| 3、pelleting process | ||||||

| 301 | elevator | TDTG36/23 | 1 | 2.20 | 2.20 | Non-return means four sides engaging process, rigidity |

| 302 | magnetic device |

|

1 |

|

|

Stainless steel, high magnetic |

| 303 | pneumatic three-way valve | TZMQ2×25/45 | 1 |

|

|

|

| 304 | pelleting-pending silo | 23 | 1 |

|

|

|

| 305 | upper material positioner |

|

1 |

|

|

|

| 306 | lower material positioner |

|

1 |

|

|

|

|

|

manual plugboard |

|

1 |

|

|

|

| 307 | feed auger | equipped with SZLH30b2 | 1 | 0.55 | 0.55 | Speed Control Feeding |

| conditioner | equipped with SZLH30b2 | 2 | 2.20 | 4.40 | heat preservation double-jacketed conditioner | |

| pellet mill | SZLH30b2 | 1 | 30.00 | 30.00 | Gear transmission, low vibration, high transmission efficiency; high yield, produce better quality feed. | |

| 308 | air-locked feeder |

|

1 | 0.55 | 0.55 |

|

|

|

counter-flow cooler | SKLN1.5 | 1 | 1.10 | 1.10 | Octagonal structure, no dead cooling |

| 309 | discharger |

|

1 |

|

|

|

| 310 | air locker | GFZ.7 | 1 | 0.75 | 0.75 |

|

| 311 | fan | 4-72N04A | 1 | 5.50 | 5.50 |

|

|

|

subtotal |

|

|

|

45.05 |

|

| 4、packing process of final product | ||||||

| 401 | elevator | TDTG36/18 | 1 | 1.50 | 1.50 | Non-return means four sides engaging process, rigidity |

| 402 | crumbler | SSLG15×100 | 1 | 5.50 | 5.50 | Fine tooth broken, broken uniform size |

| 403 | rotary sifter | SFJH80×2d | 1 | 1.10 | 1.10 |

|

| 404 | pneumatic three-way valve | TZMQ2×25/45 | 1 |

|

|

|

| 405 | final production silo |

|

2 |

|

|

A material silo, a granule silos, manual packing |

| 406 | manual bufferfly valve |

|

2 |

|

|

|

|

|

subtotal |

|

|

|

8.10 |

|

| 5、assisting process | ||||||

| 501 | fan | 4-72No4A | 1 | 5.50 | 5.50 |

|

| 502 | pulse jet dust collector | TBLMFa.30(1500) | 1 |

|

|

Imported electromagnetic valve, 4 cylinder extraction |

| 503 | air locker | GFZ.5 | 1 | 0.55 | 0.55 |

|

| 504 | air compressor |

|

1 | 7.50 | 7.50 |

|

| 505 | air dryer |

|

1 |

|

|

|

| 506 | gas tank |

|

1 |

|

|

|

|

|

container rack |

|

1 |

|

|

|

|

|

subtotal |

|

|

|

13.55 |

|

|

|

Total |

|

|

|

129.80 |

|

|

prices of complete set of feed equipment

|

||||||||

|

Project Name:3800t/year aqua-feed complete unit (∮4mm particles 1-2T / H)

|

Quote number:

|

|||||||

|

Construction unit:

|

||||||||

|

Serial

|

Name

|

Note

|

||||||

|

1、mechanical equipment (see equipment list)

|

||||||||

|

2、electronic control system

|

||||||||

|

1

|

centralized control cabinet

|

|||||||

|

2

|

Cables, wires, trunking, standard tray, and other supporting materials

|

|||||||

|

3

|

Site control cabinet

|

|||||||

|

3、container unit material

|

||||||||

|

1

|

Suction, dust removal and cooling ventilation network system

|

4-72No3.6A

|

1.0

|

4.0

|

4.0

|

|||

|

2

|

Feed pipe, a small rack, platform, pipeline materials and other non-standard items

|

|||||||

|

3

|

Standard parts, seals, and other solder pieces supporting material

|

SCY80

|

1.0

|

0.8

|

0.8

|

|||

|

4

|

Pneumatic components and air compressor accessories

|

|||||||

|

5

|

Paint (refers to the equipment up painting abroad reassembled)

|

|||||||

|

6

|

Steam piping system

|

Steam piping installation drawings and configuration checklist

|

||||||

|

4, design fees

|

free

|

|||||||

|

5, container chassis setup fee (refers prefabricated assembly factory in China)

|

||||||||

|

6, foreign on-site guidance of installation and commissioning costs

|

Foreign engineers to guide installation and commissioning of US $ 80 per day per person

|

|||||||

|

7, unforeseeable expenses

|

free

|

|||||||

|

8, expedition charges

|

||||||||

|

9, staff training costs

|

free

|

|||||||

|

Electric Control

|

||||||||

|

Note:

|

1、packaging and transportation costs are not included in the total price of the equipment

|

3, site lifting, installation tools and supplies owned by the user

|

||||||

|

2. This price is valid for MONTHS.

|

4, all site personnel expenses borne out by the demand side

|

|||||||

TOP