Our Video

Shanghai Janus Grab Co., Ltd is a global reputed grab specialist, with more than 30 years experience in grabs design, R&D, and manufacturing. Highly educated professionals in steel structure, hydraulic and electric system make Janus grabs competitive in world-wide markets.

Share

Hot Products

-

4-rope Scissors Grab

The 4-rope scissors grab is a newly bulk grab, which is suitable to crane with two drum for loading and unloading iron ore, and, coal, bulk fertilizer, and so on. The characteristic of scissor grab is newly structure, convenient operation, and light dead weight, high loading ratio. When the grab loa

122

Contact Us

- Contacter: Shanghai Janus Grab Co., Ltd

- Tel: +86-21-68855558

- Fax: +86-21-68855559

- Email: sales@janusgrab.com

-

Company Address:

No.2, Nanhai Road, Liuhe, Taicang, Jiangsu

Products

4-rope Scissors Grab

The 4-rope scissors grab is a newly bulk grab, which is suitable to crane with two drum for loading and unloading iron ore, and, coal, bulk fertilizer, and so on. The characteristic of scissor grab is newly structure, convenient operation, and light dead weight, high loading ratio. When the grab loads the iron ore, its ratio is up to 1:2.5. The grab has short opening and closing stroke, it just need a half time for withdrawing out the closing rope, comparing with the grab with long pressing rod, which could improve the loading and unloading efficiency, and decrease abrasion of grab.

Type and Size

(t)

SWL

(m3)

Volume

(t)

Dead Weight

(mm) Dimensions

(mm)

Sheave Dia.

(m)

Use Height

(mm)

Steel Rope Dia.

A

B

C

D

E

CS16[4]5.5J

16

4

5.5

4325

4475

2675

4590

2000

Ø560

10

Ø26

CS20[5]6.6J

20

5

6.6

4845

5000

2885

5110

2200

Ø650

11.5

Ø28

CS25[6.5]8.3J

25

6.5

8.3

5450

5600

3200

5730

2350

Ø720

12.5

Ø32

CS32[8]11J

32

8

11

6140

6290

3400

6400

2600

Ø800

14.5

Ø36

CS40[10.2]13.5J

40

10.2

13.5

6920

7070

3660

7200

2750

Ø880

16

Ø40

CS52[13]17J

52

13

17

7785

7935

3965

8065

3000

Ø920

18

Ø44

CS63[16.5]21J

63

16.5

21

8600

8815

4300

8930

3300

Ø1120

20

Ø48

Note: 1.As the products have been improved, we will not advice another.

2.We can design and produce the grab according to user’s demand.

4-rope Scissors Grab

The 4-rope scissors grab is a newly bulk grab, which is suitable to crane with two drum for loading and unloading iron ore, and, coal, bulk fertilizer, and so on. The characteristic of scissor grab is newly structure, convenient operation, and light dead weight, high loading ratio. When the grab loads the iron ore, its ratio is up to 1:2.5. The grab has short opening and closing stroke, it just need a half time for withdrawing out the closing rope, comparing with the grab with long pressing rod, which could improve the loading and unloading efficiency, and decrease abrasion of grab.

Type and Size

(t)

SWL

(m3)

Volume

(t)

Dead Weight

(mm) Dimensions

(mm)

Sheave Dia.

(m)

Use Height

(mm)

Steel Rope Dia.

A

B

C

D

E

CS16[4]5.5J

16

4

5.5

4325

4475

2675

4590

2000

Ø560

10

Ø26

CS20[5]6.6J

20

5

6.6

4845

5000

2885

5110

2200

Ø650

11.5

Ø28

CS25[6.5]8.3J

25

6.5

8.3

5450

5600

3200

5730

2350

Ø720

12.5

Ø32

CS32[8]11J

32

8

11

6140

6290

3400

6400

2600

Ø800

14.5

Ø36

CS40[10.2]13.5J

40

10.2

13.5

6920

7070

3660

7200

2750

Ø880

16

Ø40

CS52[13]17J

52

13

17

7785

7935

3965

8065

3000

Ø920

18

Ø44

CS63[16.5]21J

63

16.5

21

8600

8815

4300

8930

3300

Ø1120

20

Ø48

Note: 1.As the products have been improved, we will not advice another.

2.We can design and produce the grab according to user’s demand.

Motor-hydraulic Scrap Steel Grab

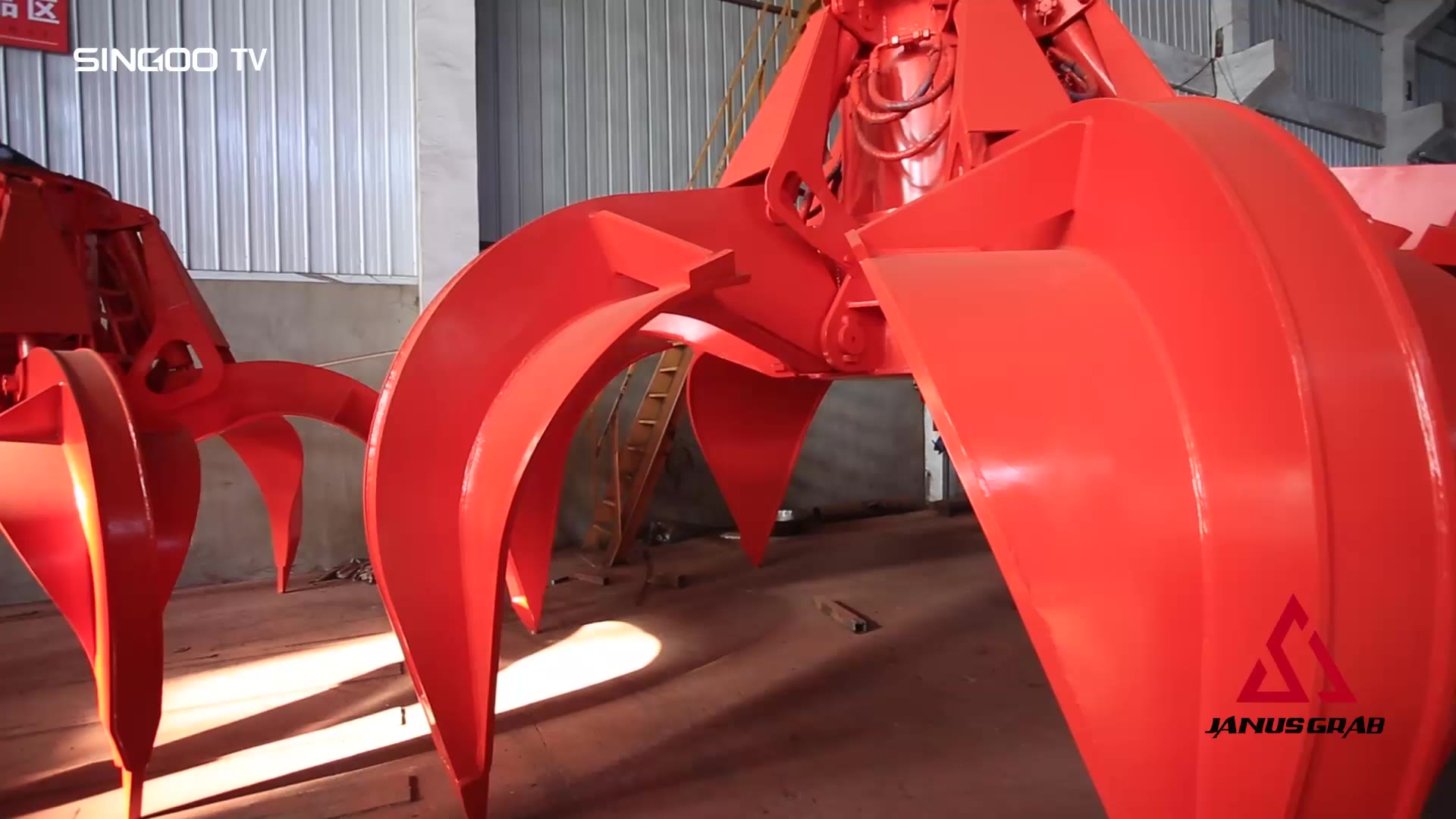

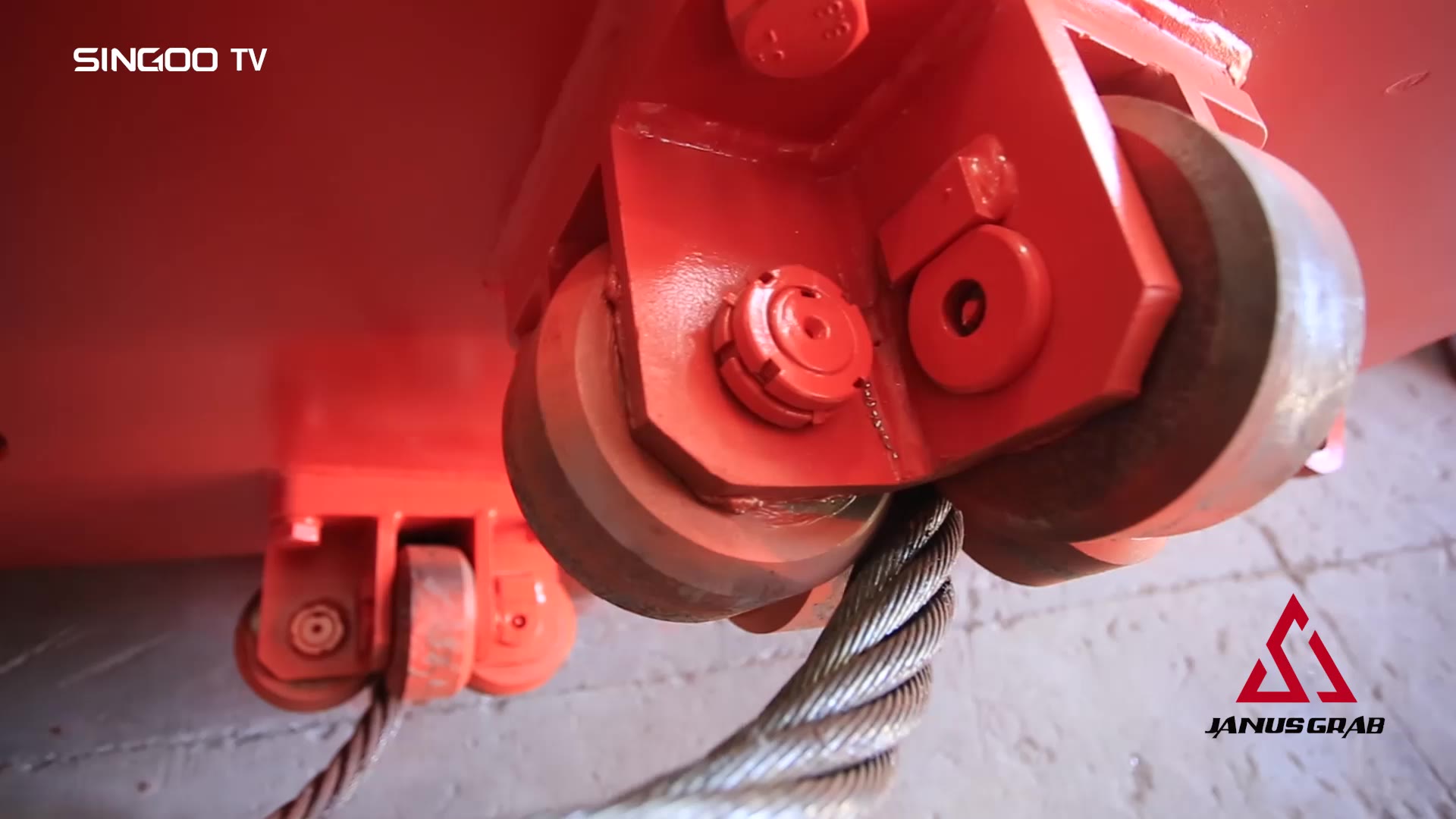

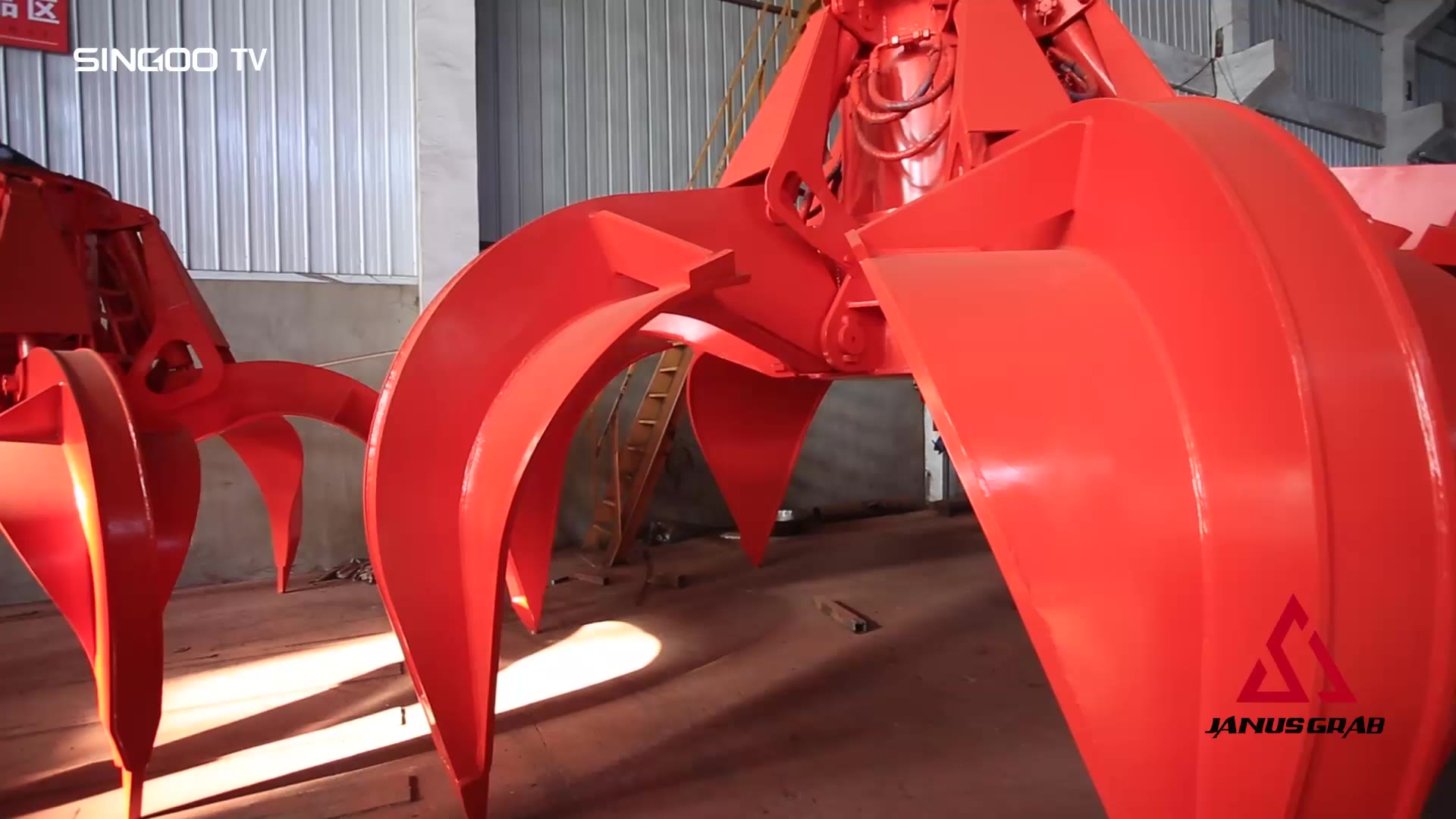

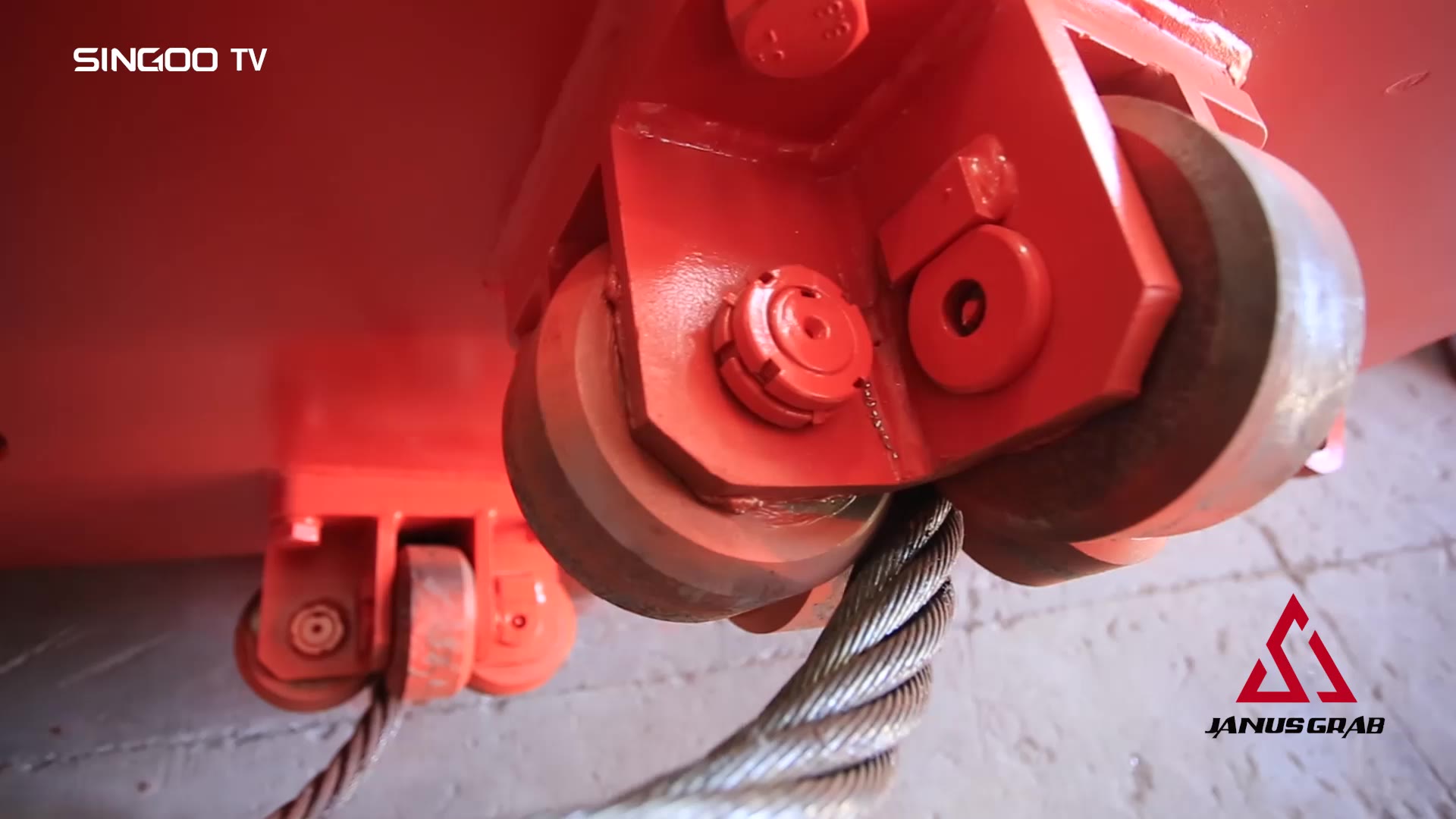

Motor-Hydraulic Scrap Steel Grab has hydraulic power and control system itself, and the hydraulic power system is imported from Europe and USA. The grab uses constant output pump and servo system. The flow of pump can change by itself according to working pressure. When the pressure reaches the max pressure, the flow is almost zero, so it can reduce the overflow, and reduce the temperature rise of oil. The opening and closing is controlled by valves or positive inversion motor which ensures the grab can positive inversion rotate frequently. The grab can be designed as half-close or full-open type with long teeth. The peels of the grab are particular, it is easy to grab scrap steel. The grab has six or eight peels, and each peel is driven by an oil cylinder, so the material won’t leak. The grab has tie-in on the grab and it is easy to connect to the crane.

It can be used to load steel scrap whose piled density is below 3t/m3

Type and Size

Volume (m3)

(mm)

Dimensions

(kg)

Empty Weight

(KW)

Power

(s)

Close time

(Kg/cm2)

Pressure

(t)

SWL

A

B

C

D

Full open

Half open

Full close

380V 50Hz

440V 60Hz

DYD5[1]2

1

1766

2626

2532

2093

1800

2000

2150

15

18.5

17

200

5

DYD8[1.5]3.2

1.5

1925

3462

3141

2730

3000

3200

3400

18.5

21

20

200

8

DYD10[2]4.2

2

2242

3565

3456

3147

4000

4200

4300

22

26

16

200

10

DYD16[3]5.5

3

2381

4184

3649

3155

5300

5500

5700

37

43

18

200

16

DYD20[4]7

4.0

2840

4505

3850

3282

6800

7000

7200

37

43

25

200

20

DYD25[5]9

5.0

3020

4807

4125

3027

8500

9000

9200

45

52

22

200

25

DYD30[6.5]9.8

6.5

3137

4983

4230

3700

9500

9800

10200

45

52

25

200

30

DYD35[8]12

8

3645

5513

4490

3850

11500

12000

12500

52

55

25

200

35

DYD40[12]16

12

4662

7188

4730

4590

15000

15500

16000

65

75

25

200

40

Note: 1.As the products have been improved, we will not advice another.

2.We can design and produce the grab according to user’s demand.

Motor-hydraulic Scrap Steel Grab

Motor-Hydraulic Scrap Steel Grab has hydraulic power and control system itself, and the hydraulic power system is imported from Europe and USA. The grab uses constant output pump and servo system. The flow of pump can change by itself according to working pressure. When the pressure reaches the max pressure, the flow is almost zero, so it can reduce the overflow, and reduce the temperature rise of oil. The opening and closing is controlled by valves or positive inversion motor which ensures the grab can positive inversion rotate frequently. The grab can be designed as half-close or full-open type with long teeth. The peels of the grab are particular, it is easy to grab scrap steel. The grab has six or eight peels, and each peel is driven by an oil cylinder, so the material won’t leak. The grab has tie-in on the grab and it is easy to connect to the crane.

It can be used to load steel scrap whose piled density is below 3t/m3

Type and Size

Volume (m3)

(mm)

Dimensions

(kg)

Empty Weight

(KW)

Power

(s)

Close time

(Kg/cm2)

Pressure

(t)

SWL

A

B

C

D

Full open

Half open

Full close

380V 50Hz

440V 60Hz

DYD5[1]2

1

1766

2626

2532

2093

1800

2000

2150

15

18.5

17

200

5

DYD8[1.5]3.2

1.5

1925

3462

3141

2730

3000

3200

3400

18.5

21

20

200

8

DYD10[2]4.2

2

2242

3565

3456

3147

4000

4200

4300

22

26

16

200

10

DYD16[3]5.5

3

2381

4184

3649

3155

5300

5500

5700

37

43

18

200

16

DYD20[4]7

4.0

2840

4505

3850

3282

6800

7000

7200

37

43

25

200

20

DYD25[5]9

5.0

3020

4807

4125

3027

8500

9000

9200

45

52

22

200

25

DYD30[6.5]9.8

6.5

3137

4983

4230

3700

9500

9800

10200

45

52

25

200

30

DYD35[8]12

8

3645

5513

4490

3850

11500

12000

12500

52

55

25

200

35

DYD40[12]16

12

4662

7188

4730

4590

15000

15500

16000

65

75

25

200

40

Note: 1.As the products have been improved, we will not advice another.

2.We can design and produce the grab according to user’s demand.

Remote Control Bulk Grab

Remote Control grab is an efficient tool for loading and unloading bulk cargo. The grab can close by lifting up hook of crane and open by remote control in the air without any additional power. The hydraulic and electric parts use the plug-in modular design, easily maintain and repair, suitable for ship ocean voyages. The Electric system and hydraulic system is water proof design, which can prevent washing of the wave and rain. Each bulk grab is test strictly by immersed under the water 24hours. Multistep buffering opens type, which reduce the impact to the grab from the crane and ensure to unload quickly. The grab can work continuous for 24 hours with low trouble rate. Grab uses less energy, a full battery can keep the use of more than 180 hours. Easy operation, the crane does not need any other auxiliary equipment. The grab can service after being put on the hook. Now the grabs are widely used in bulk vessels, ports, and are exported in batches.

It can be used to bulk a lot of kind material which the piled density is 0.9-2.5t/m3

Type

Volume(m3)

Crane Capacity

(t)

Dead Weight

(t)

Dimensions (mm)

Sheave Dia. (mm)

Steel Rope Dia. (mm)

A

B

C

D

E

YK10[3-6]4.5

3-6

10

4.5

2600

3338

3756

4071

2700

Ø445

Ø24

YK14[4-7]6

4-7

14

6

2780

3398

4092

4448

2800

Ø520

Ø28

YK16[4-8]7

4-8

16

7

2780

3398

4092

4448

3000

Ø520

Ø28

YK20[5-10]8

5-10

20

8

2810

3591

4192

4513

3560

Ø560

Ø32

YK25[6-12]9.5

6-12

25

9.5

3000

3837

4487

4850

4100

Ø650

Ø36

YK28[8-16]10

8-16

28

10

3060

3887

4559

4881

4320

Ø650

Ø36

YK32[10-20]13.5

10-20

35

14

3270

4109

5008

5391

4600

Ø720

Ø40

YK40[12-24]17

12-24

40

17

3520

4374

5136

5495

4700

Ø800

Ø45

YK50[15-30]21

15-30

50

21

4000

4873

5850

6072

4900

Ø880

Ø52

Remote Control Bulk Grab

Remote Control grab is an efficient tool for loading and unloading bulk cargo. The grab can close by lifting up hook of crane and open by remote control in the air without any additional power. The hydraulic and electric parts use the plug-in modular design, easily maintain and repair, suitable for ship ocean voyages. The Electric system and hydraulic system is water proof design, which can prevent washing of the wave and rain. Each bulk grab is test strictly by immersed under the water 24hours. Multistep buffering opens type, which reduce the impact to the grab from the crane and ensure to unload quickly. The grab can work continuous for 24 hours with low trouble rate. Grab uses less energy, a full battery can keep the use of more than 180 hours. Easy operation, the crane does not need any other auxiliary equipment. The grab can service after being put on the hook. Now the grabs are widely used in bulk vessels, ports, and are exported in batches.

It can be used to bulk a lot of kind material which the piled density is 0.9-2.5t/m3

Type

Volume(m3)

Crane Capacity

(t)

Dead Weight

(t)

Dimensions (mm)

Sheave Dia. (mm)

Steel Rope Dia. (mm)

A

B

C

D

E

YK10[3-6]4.5

3-6

10

4.5

2600

3338

3756

4071

2700

Ø445

Ø24

YK14[4-7]6

4-7

14

6

2780

3398

4092

4448

2800

Ø520

Ø28

YK16[4-8]7

4-8

16

7

2780

3398

4092

4448

3000

Ø520

Ø28

YK20[5-10]8

5-10

20

8

2810

3591

4192

4513

3560

Ø560

Ø32

YK25[6-12]9.5

6-12

25

9.5

3000

3837

4487

4850

4100

Ø650

Ø36

YK28[8-16]10

8-16

28

10

3060

3887

4559

4881

4320

Ø650

Ø36

YK32[10-20]13.5

10-20

35

14

3270

4109

5008

5391

4600

Ø720

Ø40

YK40[12-24]17

12-24

40

17

3520

4374

5136

5495

4700

Ø800

Ø45

YK50[15-30]21

15-30

50

21

4000

4873

5850

6072

4900

Ø880

Ø52

4-rope Scissors Grab

The 4-rope scissors grab is a newly bulk grab, which is suitable to crane with two drum for loading and unloading iron ore, and, coal, bulk fertilizer, and so on. The characteristic of scissor grab is newly structure, convenient operation, and light dead weight, high loading ratio. When the grab loads the iron ore, its ratio is up to 1:2.5. The grab has short opening and closing stroke, it just need a half time for withdrawing out the closing rope, comparing with the grab with long pressing rod, which could improve the loading and unloading efficiency, and decrease abrasion of grab.

Type and Size

(t)

SWL

(m3)

Volume

(t)

Dead Weight

(mm) Dimensions

(mm)

Sheave Dia.

(m)

Use Height

(mm)

Steel Rope Dia.

A

B

C

D

E

CS16[4]5.5J

16

4

5.5

4325

4475

2675

4590

2000

Ø560

10

Ø26

CS20[5]6.6J

20

5

6.6

4845

5000

2885

5110

2200

Ø650

11.5

Ø28

CS25[6.5]8.3J

25

6.5

8.3

5450

5600

3200

5730

2350

Ø720

12.5

Ø32

CS32[8]11J

32

8

11

6140

6290

3400

6400

2600

Ø800

14.5

Ø36

CS40[10.2]13.5J

40

10.2

13.5

6920

7070

3660

7200

2750

Ø880

16

Ø40

CS52[13]17J

52

13

17

7785

7935

3965

8065

3000

Ø920

18

Ø44

CS63[16.5]21J

63

16.5

21

8600

8815

4300

8930

3300

Ø1120

20

Ø48

Note: 1.As the products have been improved, we will not advice another.

2.We can design and produce the grab according to user’s demand.

4-rope Scissors Grab

The 4-rope scissors grab is a newly bulk grab, which is suitable to crane with two drum for loading and unloading iron ore, and, coal, bulk fertilizer, and so on. The characteristic of scissor grab is newly structure, convenient operation, and light dead weight, high loading ratio. When the grab loads the iron ore, its ratio is up to 1:2.5. The grab has short opening and closing stroke, it just need a half time for withdrawing out the closing rope, comparing with the grab with long pressing rod, which could improve the loading and unloading efficiency, and decrease abrasion of grab.

Type and Size

(t)

SWL

(m3)

Volume

(t)

Dead Weight

(mm) Dimensions

(mm)

Sheave Dia.

(m)

Use Height

(mm)

Steel Rope Dia.

A

B

C

D

E

CS16[4]5.5J

16

4

5.5

4325

4475

2675

4590

2000

Ø560

10

Ø26

CS20[5]6.6J

20

5

6.6

4845

5000

2885

5110

2200

Ø650

11.5

Ø28

CS25[6.5]8.3J

25

6.5

8.3

5450

5600

3200

5730

2350

Ø720

12.5

Ø32

CS32[8]11J

32

8

11

6140

6290

3400

6400

2600

Ø800

14.5

Ø36

CS40[10.2]13.5J

40

10.2

13.5

6920

7070

3660

7200

2750

Ø880

16

Ø40

CS52[13]17J

52

13

17

7785

7935

3965

8065

3000

Ø920

18

Ø44

CS63[16.5]21J

63

16.5

21

8600

8815

4300

8930

3300

Ø1120

20

Ø48

Note: 1.As the products have been improved, we will not advice another.

2.We can design and produce the grab according to user’s demand.

Motor-hydraulic Scrap Steel Grab

Motor-Hydraulic Scrap Steel Grab has hydraulic power and control system itself, and the hydraulic power system is imported from Europe and USA. The grab uses constant output pump and servo system. The flow of pump can change by itself according to working pressure. When the pressure reaches the max pressure, the flow is almost zero, so it can reduce the overflow, and reduce the temperature rise of oil. The opening and closing is controlled by valves or positive inversion motor which ensures the grab can positive inversion rotate frequently. The grab can be designed as half-close or full-open type with long teeth. The peels of the grab are particular, it is easy to grab scrap steel. The grab has six or eight peels, and each peel is driven by an oil cylinder, so the material won’t leak. The grab has tie-in on the grab and it is easy to connect to the crane.

It can be used to load steel scrap whose piled density is below 3t/m3

Type and Size

Volume (m3)

(mm)

Dimensions

(kg)

Empty Weight

(KW)

Power

(s)

Close time

(Kg/cm2)

Pressure

(t)

SWL

A

B

C

D

Full open

Half open

Full close

380V 50Hz

440V 60Hz

DYD5[1]2

1

1766

2626

2532

2093

1800

2000

2150

15

18.5

17

200

5

DYD8[1.5]3.2

1.5

1925

3462

3141

2730

3000

3200

3400

18.5

21

20

200

8

DYD10[2]4.2

2

2242

3565

3456

3147

4000

4200

4300

22

26

16

200

10

DYD16[3]5.5

3

2381

4184

3649

3155

5300

5500

5700

37

43

18

200

16

DYD20[4]7

4.0

2840

4505

3850

3282

6800

7000

7200

37

43

25

200

20

DYD25[5]9

5.0

3020

4807

4125

3027

8500

9000

9200

45

52

22

200

25

DYD30[6.5]9.8

6.5

3137

4983

4230

3700

9500

9800

10200

45

52

25

200

30

DYD35[8]12

8

3645

5513

4490

3850

11500

12000

12500

52

55

25

200

35

DYD40[12]16

12

4662

7188

4730

4590

15000

15500

16000

65

75

25

200

40

Note: 1.As the products have been improved, we will not advice another.

2.We can design and produce the grab according to user’s demand.

Motor-hydraulic Scrap Steel Grab

Motor-Hydraulic Scrap Steel Grab has hydraulic power and control system itself, and the hydraulic power system is imported from Europe and USA. The grab uses constant output pump and servo system. The flow of pump can change by itself according to working pressure. When the pressure reaches the max pressure, the flow is almost zero, so it can reduce the overflow, and reduce the temperature rise of oil. The opening and closing is controlled by valves or positive inversion motor which ensures the grab can positive inversion rotate frequently. The grab can be designed as half-close or full-open type with long teeth. The peels of the grab are particular, it is easy to grab scrap steel. The grab has six or eight peels, and each peel is driven by an oil cylinder, so the material won’t leak. The grab has tie-in on the grab and it is easy to connect to the crane.

It can be used to load steel scrap whose piled density is below 3t/m3

Type and Size

Volume (m3)

(mm)

Dimensions

(kg)

Empty Weight

(KW)

Power

(s)

Close time

(Kg/cm2)

Pressure

(t)

SWL

A

B

C

D

Full open

Half open

Full close

380V 50Hz

440V 60Hz

DYD5[1]2

1

1766

2626

2532

2093

1800

2000

2150

15

18.5

17

200

5

DYD8[1.5]3.2

1.5

1925

3462

3141

2730

3000

3200

3400

18.5

21

20

200

8

DYD10[2]4.2

2

2242

3565

3456

3147

4000

4200

4300

22

26

16

200

10

DYD16[3]5.5

3

2381

4184

3649

3155

5300

5500

5700

37

43

18

200

16

DYD20[4]7

4.0

2840

4505

3850

3282

6800

7000

7200

37

43

25

200

20

DYD25[5]9

5.0

3020

4807

4125

3027

8500

9000

9200

45

52

22

200

25

DYD30[6.5]9.8

6.5

3137

4983

4230

3700

9500

9800

10200

45

52

25

200

30

DYD35[8]12

8

3645

5513

4490

3850

11500

12000

12500

52

55

25

200

35

DYD40[12]16

12

4662

7188

4730

4590

15000

15500

16000

65

75

25

200

40

Note: 1.As the products have been improved, we will not advice another.

2.We can design and produce the grab according to user’s demand.

Remote Control Bulk Grab

Remote Control grab is an efficient tool for loading and unloading bulk cargo. The grab can close by lifting up hook of crane and open by remote control in the air without any additional power. The hydraulic and electric parts use the plug-in modular design, easily maintain and repair, suitable for ship ocean voyages. The Electric system and hydraulic system is water proof design, which can prevent washing of the wave and rain. Each bulk grab is test strictly by immersed under the water 24hours. Multistep buffering opens type, which reduce the impact to the grab from the crane and ensure to unload quickly. The grab can work continuous for 24 hours with low trouble rate. Grab uses less energy, a full battery can keep the use of more than 180 hours. Easy operation, the crane does not need any other auxiliary equipment. The grab can service after being put on the hook. Now the grabs are widely used in bulk vessels, ports, and are exported in batches.

It can be used to bulk a lot of kind material which the piled density is 0.9-2.5t/m3

Type

Volume(m3)

Crane Capacity

(t)

Dead Weight

(t)

Dimensions (mm)

Sheave Dia. (mm)

Steel Rope Dia. (mm)

A

B

C

D

E

YK10[3-6]4.5

3-6

10

4.5

2600

3338

3756

4071

2700

Ø445

Ø24

YK14[4-7]6

4-7

14

6

2780

3398

4092

4448

2800

Ø520

Ø28

YK16[4-8]7

4-8

16

7

2780

3398

4092

4448

3000

Ø520

Ø28

YK20[5-10]8

5-10

20

8

2810

3591

4192

4513

3560

Ø560

Ø32

YK25[6-12]9.5

6-12

25

9.5

3000

3837

4487

4850

4100

Ø650

Ø36

YK28[8-16]10

8-16

28

10

3060

3887

4559

4881

4320

Ø650

Ø36

YK32[10-20]13.5

10-20

35

14

3270

4109

5008

5391

4600

Ø720

Ø40

YK40[12-24]17

12-24

40

17

3520

4374

5136

5495

4700

Ø800

Ø45

YK50[15-30]21

15-30

50

21

4000

4873

5850

6072

4900

Ø880

Ø52

Remote Control Bulk Grab

Remote Control grab is an efficient tool for loading and unloading bulk cargo. The grab can close by lifting up hook of crane and open by remote control in the air without any additional power. The hydraulic and electric parts use the plug-in modular design, easily maintain and repair, suitable for ship ocean voyages. The Electric system and hydraulic system is water proof design, which can prevent washing of the wave and rain. Each bulk grab is test strictly by immersed under the water 24hours. Multistep buffering opens type, which reduce the impact to the grab from the crane and ensure to unload quickly. The grab can work continuous for 24 hours with low trouble rate. Grab uses less energy, a full battery can keep the use of more than 180 hours. Easy operation, the crane does not need any other auxiliary equipment. The grab can service after being put on the hook. Now the grabs are widely used in bulk vessels, ports, and are exported in batches.

It can be used to bulk a lot of kind material which the piled density is 0.9-2.5t/m3

Type

Volume(m3)

Crane Capacity

(t)

Dead Weight

(t)

Dimensions (mm)

Sheave Dia. (mm)

Steel Rope Dia. (mm)

A

B

C

D

E

YK10[3-6]4.5

3-6

10

4.5

2600

3338

3756

4071

2700

Ø445

Ø24

YK14[4-7]6

4-7

14

6

2780

3398

4092

4448

2800

Ø520

Ø28

YK16[4-8]7

4-8

16

7

2780

3398

4092

4448

3000

Ø520

Ø28

YK20[5-10]8

5-10

20

8

2810

3591

4192

4513

3560

Ø560

Ø32

YK25[6-12]9.5

6-12

25

9.5

3000

3837

4487

4850

4100

Ø650

Ø36

YK28[8-16]10

8-16

28

10

3060

3887

4559

4881

4320

Ø650

Ø36

YK32[10-20]13.5

10-20

35

14

3270

4109

5008

5391

4600

Ø720

Ø40

YK40[12-24]17

12-24

40

17

3520

4374

5136

5495

4700

Ø800

Ø45

YK50[15-30]21

15-30

50

21

4000

4873

5850

6072

4900

Ø880

Ø52