JM provides machinery machining parts, and parts assembling services, owns horizontal machining center, five/four-axis linkage CNC machines, turn-mill combination, large-sized CNC turning center, and the ability of all-round comprehensive machining services of precision CNC lathe, automatic lathe and various kinds of general machining equipment. JM can implement machining of each series of high-precision mechanical parts, and turning, grinding and precision numerical control of various shapes of materials e.g. Sectional material, disk type parts, casting parts, forging parts, pipe fittings, bend pipe materials and squeezing parts. JM may design and develop new products according to the drawings and samples of customers.

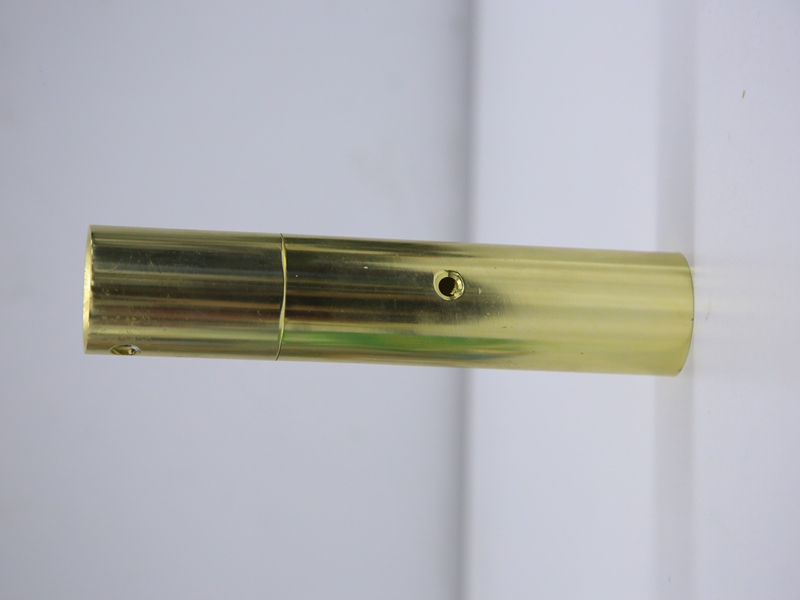

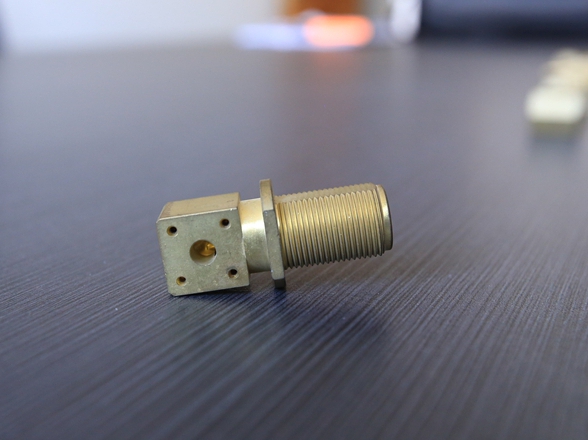

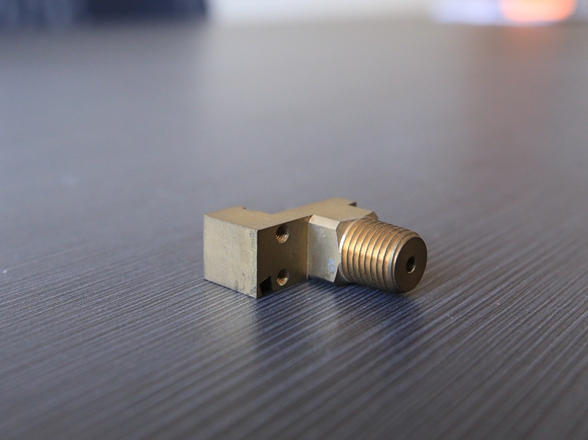

BRASS MACHINING PARTS

|

|

|

|

JMBMP |

JMBMP-001 |

JMBMP-002 |

|

|

|

|

|

|

|

|

JMBMP-003 |

JMBMP-004 |

JMBMP-005 |

|

|

|

|

|

|

|

|

JMBMP-006 |

JMBMP-007 |

JMBMP-008 |

|

|

|

|

|

|

|

|

JMBMP-009 |

JMBMP-010 |

JMBMP-011 |

|

|

|

|

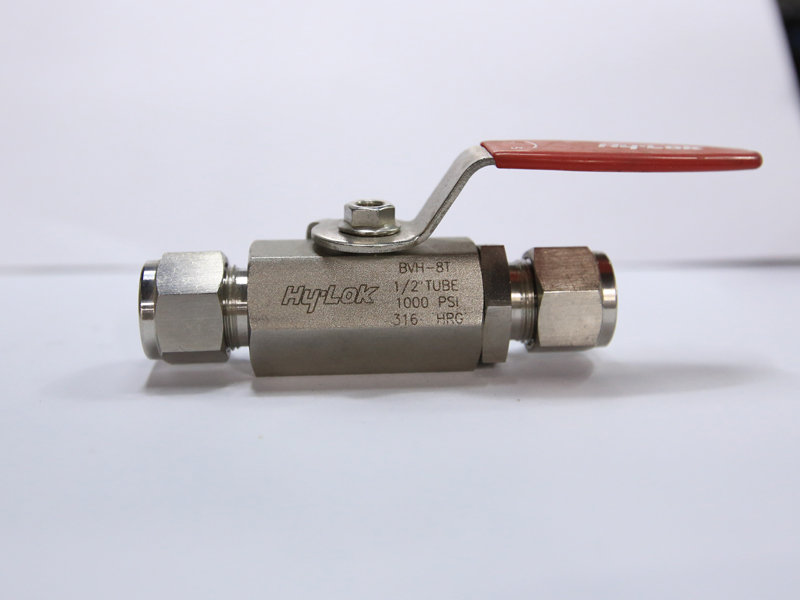

STEEL MACHINING PARTS

|

|

|

|

JMSMP |

JMSMP-001 |

JMSMP-002 |

|

|

|

|

|

|

|

|

JMSMP-003 |

JMSMP-004 |

JMSMP-005 |

|

|

|

|

|

|

|

|

JMSMP-006 |

JMSMP-007 |

JMSMP-008 |

|

|

|

|

|

|

|

|

JMSMP-009 |

JMSMP-010 |

JMSMP-011 |

|

|

|

|

|

|

|

|

JMSMP-012 |

JMSMP-013 |

|

|

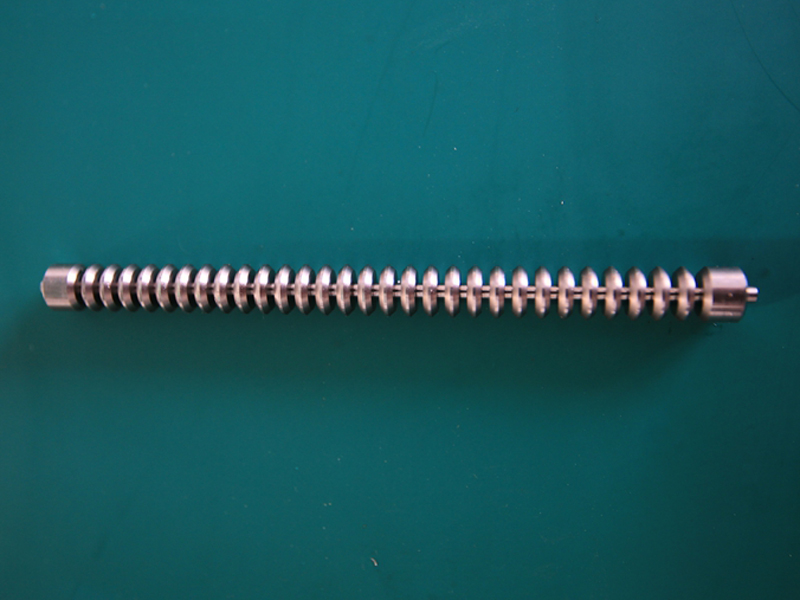

CNC Turning Parts-CANADA PROJECT |

CNC Turning Parts-CANADA PROJECT |

|

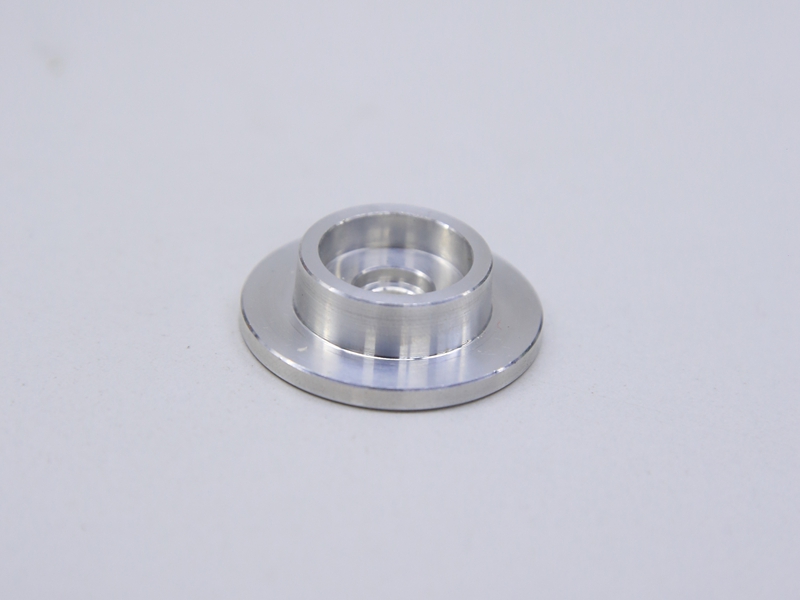

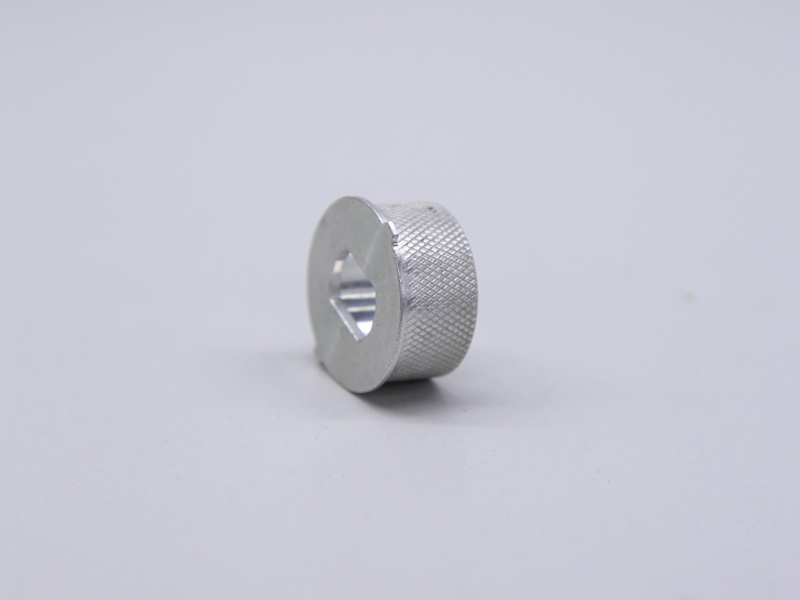

ALUMINUM MACHINING PARTS

|

|

|

|

JMAMP-001 |

JMAMP-002 |

JMAMP-003 |

|

|

|

|

|

|

|

|

JMAMP-004 |

JMAMP-005 |

JMAMP-006 |

|

|

|

|

|

|

|

|

JMAMP-007 |

JMAMP-008 |

JMAMP-009 |

|

|

|

|

|

Machining Parts |

|

|

Applicable Material: |

Aluminum/zinc alloy, iron, steel alloy, plastic, brass, steel, and stainless steel |

|

Surface treatmen: |

polishing, zinc plating, nickel plating, chrome plating, anodizing, EDM, Black, Nitrogenation. |

|

Packaging: |

Standard package/ Pallet or container/ as per customized specifications. |

|

Materials: |

Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. |

|

Brass Alloy::3602 / 2604 / H59 / H62 / etc. |

|

|

Stainless Steel Alloy:303 / 304 / 316 / 412 /316/212/316/SUS400, etc. |

|

|

Steel Alloy:Carbon Steel / Die Steel / etc. |

|

|

Other Special Materials::Bronze/ Copper alloys/ Lucite / Nylon / Bakelite /Non Metallic Material Parts etc. |

|

|

Machining Equipment: |

4-axis CNC Machining Center, CNC Lathe, High Speed Electric Spark Puncher,Milling Machine ,Grinding Machine, CNC Lathes , Wire-cuts, Laser Cuts , CNC Shearing Machines ,CNC Bending Machines, etc. |

|

Quality Control and Detection Equipment: |

Our QC department work is inspection and final inspection. We promise you as below: |

|

1. Check the raw material before the production.. |

|

|

2. Have inspection during the production. |

|

|

3. Make 100% inspection before the shipment. |

|

|

Coordinate Measuring Machine, Calipers, Microscope, Micrometer,DEM, Height Meter and 00 Level Marbel Panel, Ring Gauge, Three Pin, Thread Gauge. |

|

|

Usage: |

Heavy machinery, Marine equipment parts, Vehicles,Printing machines, Food processing machines, Textile machines,Electronic machines, etc. |

|

Quality Assurance: |

ISO9001:2008, TUV Certified. |

|

Production Output: |

Based on customer's drawing or samples. Usually 300.000 pieces/ month. |

|

Experience: |

7 years of professional; OEM service |

|

Lead Time: |

Usually based on customer's drawing or samples. |

|

File Formats: |

Pro/Engineer, AutoCAD(DXF,DWG), PDF, TIF , UG, Mastercam , Caxa, Pullmill, etc. |

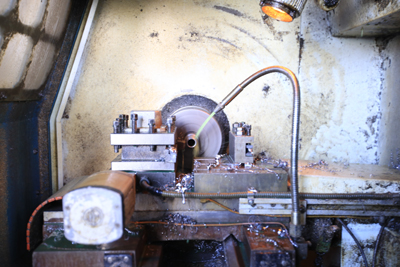

Description of turning process: Turning parts is processed on the lathe by using the rotation

motion of workpiece and linear motion or curve motion of cutters to change the

shape and size of blanks according to the requirements of drawings.  Turning

processing is a method for machining the workpiece by using the rotation of

workpiece relative to the cutters on the lathe. The cutting energy of turning

processing is mainly provided by the workpiece rather than the cutters. Turning

is the most basic and most common machining method and plays an important role

in production. Turning is suitable for processing of rotary surface and most

workpieces having rotary surfaces can be processed with turning method,

including inner and outer cylindrical surfaces, inner and outer conical

surfaces, end surface, groove, thread and rotary forming surface, etc. The

cutter used is mainly lathe tool. The turning precision is IT11-IT7 generally,

some can be IT6 and the surface roughness Ra can be 12.5-0.8um.

Turning

processing is a method for machining the workpiece by using the rotation of

workpiece relative to the cutters on the lathe. The cutting energy of turning

processing is mainly provided by the workpiece rather than the cutters. Turning

is the most basic and most common machining method and plays an important role

in production. Turning is suitable for processing of rotary surface and most

workpieces having rotary surfaces can be processed with turning method,

including inner and outer cylindrical surfaces, inner and outer conical

surfaces, end surface, groove, thread and rotary forming surface, etc. The

cutter used is mainly lathe tool. The turning precision is IT11-IT7 generally,

some can be IT6 and the surface roughness Ra can be 12.5-0.8um.

Advantages: It has wide processing range and strong adaptability, ranging from steel, cast iron and its alloy to such non-ferrous metals and some non-metallic materials as copper and aluminum; it can not only process parts with single axis, but also multi-axis parts including crankshaft, eccentric wheel or disc cam; it has high productivity; cutters are simple, facilitating the manufacturing, grinding and installation. With these advantages, turning plays an important role in production of single piece and small batch, or mass production as well as in the maintenance and repair of machinery.

|

|

|

|

|

|

|