LS shrinkable sleeve labeling machine

59

Share

Description

Application

1. Electronic and optical fiber eye: tail surface and electronic eye are combined to improve the cutting precision.

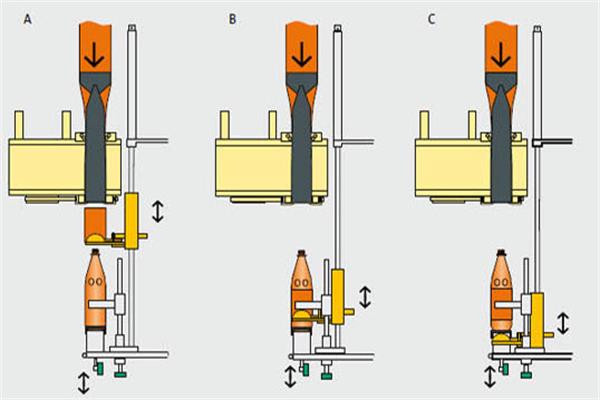

2. The change of cutting head is divided into three parts according to the diameter of the bottle:

(1)25-50mm

(2)50-95mm

(3)95-125mm

Within the range of the specification, only blade needs changing and it’s rapid and convenient. By touching the screen, automatic searching and position is applied.

3. Bottle carrying positioning system: xed belts are applied to transmit bottles and simultaneously adjust the machine to control the highly sensitive screen operation with people-controlling machine. After the label is cased, it is made smooth by the brushes.The operating speed of the fixed bottle-carrying belts can be controlled simultaneously with that of the conveyer.

4. Microcomputer is used to control the machine at a constant temperature so that time and power is saved. The stove can be opened and cleaned during to the production. Rolling stove is separated by glass fiber and the outer part does not radiate heat to ensure safety.Both temperature and wind power can be adjusted according to the height of conveyer. Rapid heating and thermostatic contacting characterize contracting stove. Either steaming or electro thermal power can be used to contract.

Technical Parameter

2. The change of cutting head is divided into three parts according to the diameter of the bottle:

(1)25-50mm

(2)50-95mm

(3)95-125mm

Within the range of the specification, only blade needs changing and it’s rapid and convenient. By touching the screen, automatic searching and position is applied.

3. Bottle carrying positioning system: xed belts are applied to transmit bottles and simultaneously adjust the machine to control the highly sensitive screen operation with people-controlling machine. After the label is cased, it is made smooth by the brushes.The operating speed of the fixed bottle-carrying belts can be controlled simultaneously with that of the conveyer.

4. Microcomputer is used to control the machine at a constant temperature so that time and power is saved. The stove can be opened and cleaned during to the production. Rolling stove is separated by glass fiber and the outer part does not radiate heat to ensure safety.Both temperature and wind power can be adjusted according to the height of conveyer. Rapid heating and thermostatic contacting characterize contracting stove. Either steaming or electro thermal power can be used to contract.

|

Model |

LS series |

|

Main engine size |

1100*1300*2000mm |

|

Main engine production speed |

100bottles/min 250bottles/min 400bottles/min |

|

Main engine power supply |

380V 220V |

|

Main engine power |

1-2.5kw |

|

Shrink power |

15KW |

|

Label length |

25mm-280mm |

|

Label thickness |

0.035mm-0.13mm |

|

Label material |

PVC,PET,OPS |

|

Bottle height |

15mm-320mm |

|

Bottle diameter |

28mm-125mm |

|

Bottle Shape |

Round, square, elliptic,rectangular |

Products

- Automatic Labeling Machine

- Automatic Filling Machine

- Form Fill Seal Pouch Packing Machine

- HFS premade pouch packing machine

- Vertical sachet packing machine

- Rotary Premade pouch packing machine

- Automatic Capping Machine

- Case & carton Erector Machine

- Case &carton Packing Machine

- Case & carton Sealing Machine

- Palletizer robot Machine

- Automatic Filling Line

- Pouch Packing line

- Other packing machine

- Selection Guide

- Turnkey Project

TOP