Digital Factory is defined as a new production organization, that is to make the simulation, evaluation and optimization of the entire production process in a computer virtual environment, and then extended to the entire product life cycle. Its essence is to achieve the information integration. Through the data collection of all the processes of the enterprise, building databases then turn a physical plant into a digital factory. The Smart Factory is based on Digital Factory and by the use of the Internet of Things and monitoring techniques, enhancesthe information management service, and ultimately achieves the goals ofoptimal production, no intervention by human, best efficiency, dynamic equilibrium, and human-computer interaction.

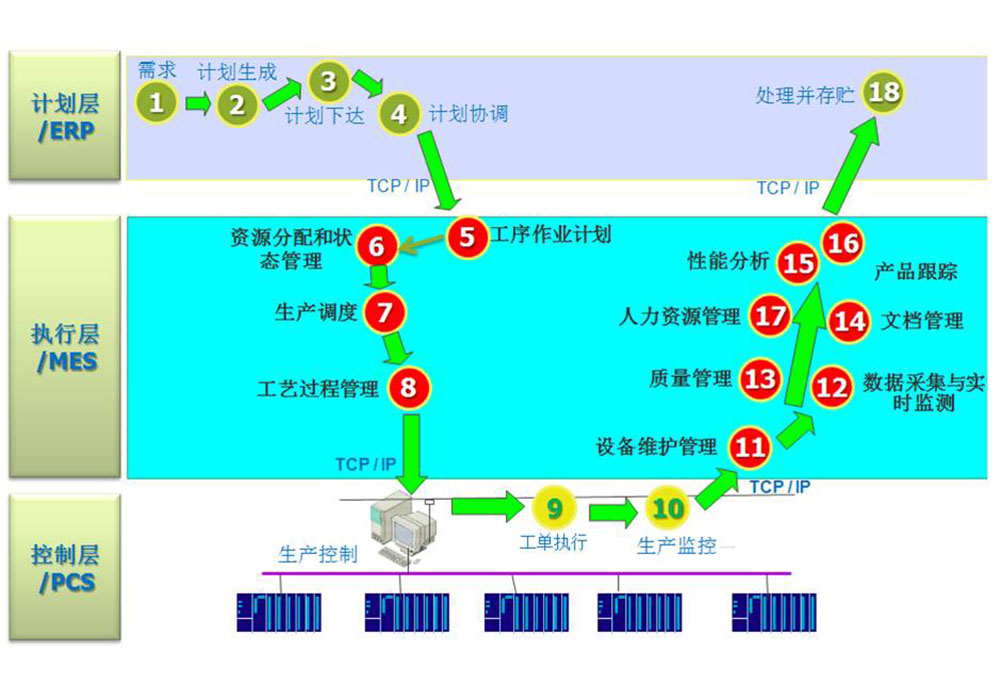

The MES system connects the device control systems, barcode scanners, workshop PCs, large-screen display terminals, barcode printers, network printers and other devices via theindustrial Ethernet to realize the data communication. At the same time,by accessinginto the plant backbone network through a router, the MES integratesthe enterprise management ERP data and executive-level PCS data into closed loop information to improve the level of automation. MES data collection supports barcode, RFID handheld terminal, automatic measuring device, electronic billboard, smart phone, iPad, PLC, sensor, tablet PC and other terminals.

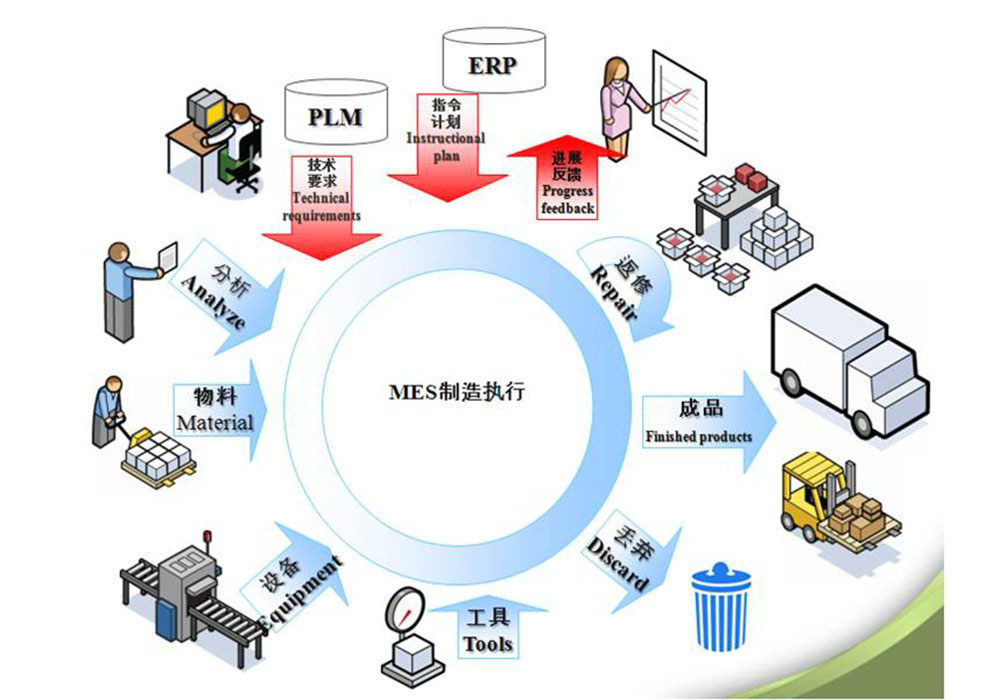

The MES system is a production information management system to the executive-level of the manufacturing plant, mainly to achieve the information management of the entire production process from the order to the product. The main functions include manufacturing data management, plan and schedule management, production scheduling management, inventory management, quality management, human resources management, equipment management, tools management, procurement management, cost management, project management, manufacturing process control, the underlying data integrated analysis, the upper data integrated decomposition, etc. achieving the information exchange between the planning layer and controlling layer. It is the key of realizing the digital and intelligent factory.

Our company is committed to the design of the overall solution, integration, implementation and service of the discrete manufacturing smart plant. By investigation, understanding and optimization recommendations of the early demand company manufacturing technique, design and supply the fully integrated logistics solution which can adapt to their intelligent production needs.In addition, on the basis of intelligence production and intelligent logistics, providing the MES system for enterprises which covers the production model creation, order management, production management, production scheduling, equipment management, quality management, traceability and exception management, data analysis, reporting and other functions. This system can realize the plants intelligent production, as well as open up the data barriers between various systems, set up the standard data interface and horizontally integrate the ERP / WMS / PCS, then achieve the data sharing between systems. Shanghai Triowin Co. has become a whole industry chain integration supplier, including the production off line conveying, automatic packaging, picking up and packing, palletizing, stereoscopic warehouse, AGV intelligent transportation.As the successful development of the stereoscopic warehouse, AGV, WMS, WCS, RFID dynamic tracking, Shanghai TriowinCo. looks forward to the common development on theDigital Factory andIntelligent Plant projects with you!