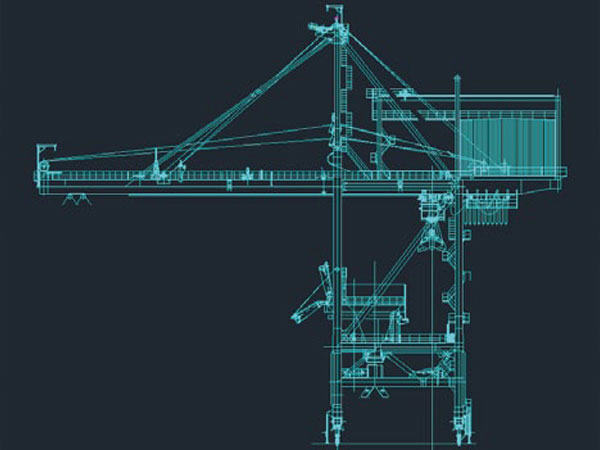

Grab Ship Unloader

Details

The capacity range of the standard model is 400-3000 TPH. The GGU series is suitable to the vessels from 3000DWT to 200000DWT and applicable to different water levels and the material dump height.

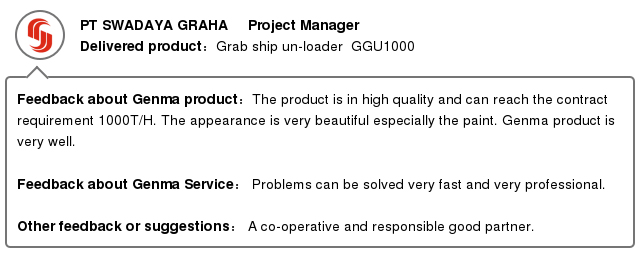

Reference

Testimonials

Feature

Feature

Genma GGU series grab ship unloader is often applied in bulk material discharging, which using the steel wire rope controlling the grab to capture material and unload to the conveyor or trucks.

Parameter

Wire rope drive type: grab closing/lifting、lowing and trolley traveling drive in the machine Room. The trolley is towed by the wire rope. The trolley is light weight and high speed.

Crab trolley type: grab closing/lifting、lowing and trolley traveling drive on the trolley. Optimized cabin design with broad vision and easy to control the grab. Shorter steel wire rope and less wear.

-

-

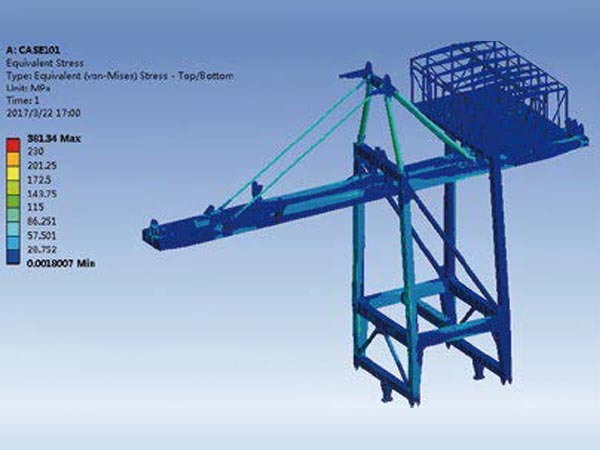

ANSYS Calculation and 3D Model Design

ANSYS Calculation and 3D Model Design

All structures of Genma grab ship unloader are checked by ANSYS

to ensure the strength, rigidity and stability.All parts are

virtually assembled through 3D modeling before manufacture.

-

-

-

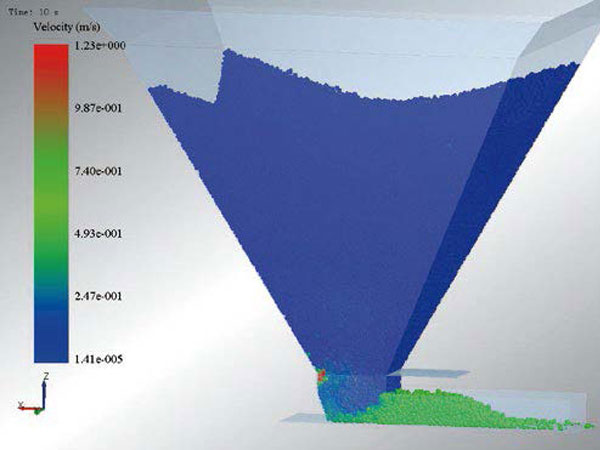

Edem: Bulksim Simulation

Edem: Bulksim Simulation

-

-

-

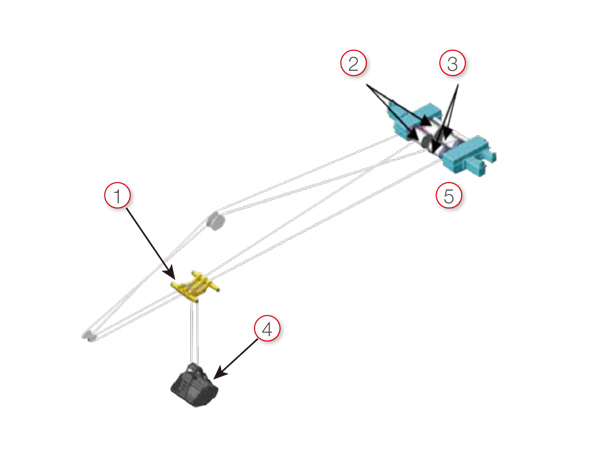

Four-reel Mechanical Differential Lifting/opening and Closing Mechanism and Traction Trolley

Four-reel Mechanical Differential Lifting/opening and Closing Mechanism and Traction Trolley

1—Grab trolley

2—Lifting drum

3—Closing drum

4—Grab

5—Planetary differential reducer

-

-

-

Low weight of the machine

Low weight of the machine

We combine formerly separate lifting, opening and closing mechanisms and trolley traction into one simple structure with a wire winding system that is wear-resistant, which requires less wire rope and reduce the total weight.

-

-

-

New and efficient, green and environmental protection

New and efficient, green and environmental protection

Adding electrical energy feedback function interface, so potential gravitational energy is converted to electrical energy, which can effectively reduce the energy consumption;Besides that, we also consider to optimize the speed of each mechanism.

-

-

-

Structure optimization

Structure optimization

The crane optimization design was carried out in following two ways:

1. the center of gravity height of the crane and the windward surface height.

2. by means of speed optimization of each mechanism and electric control, to optimize the performance.

-

-

-

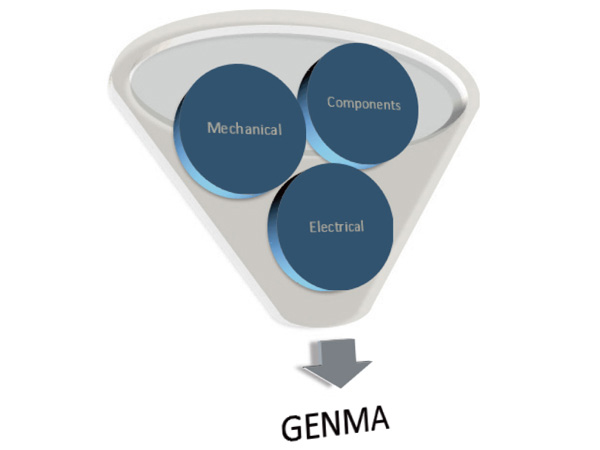

stability

stability

Well communication between mechanical, electrical and components, if considering the crane as a human, the steel structure is the skeleton, program is the core of wisdom, and the components should be organ, these three elements are indispensable.

-

-

-

High intelligence

High intelligence

Remote monitoring system

Fault diagnosis system

Energy feedback system…

…

-

The capacity range of the standard model is 400-3000 TPH. The GGU series is suitable to the vessels from 3000DWT to 200000DWT and applicable to different water levels and the material dump height.

Typical Model List

| Parameters | 400 t/h | 1750 t/h | 3000 t/h |

|---|---|---|---|

|

Max. Hoisting speed |

65 m/min | 130 m/min | 190 m/min |

|

Max. opening/closing speed |

130 m/min | 180 m/min | 190 m/min |

|

Total lift height |

20 m | 34.5 m | 42.6 m |

| Above rail | 13 m | 22 m | 21.3 m |

| Below rail | 7 m | 12.5 m | 21.3 m |

|

MAX. Trolley traversing speed |

80 m/min | 220 m/min | 240 m/min |

|

Outreach from seaside rail |

19 m | 33 m | 40 m |

|

Backreach from landside rail |

7.5 m | 14 m | 44 m |

|

Gantry traveling speed |

0~20 m/min | 0~20 m/min | 0~25 m/min |

| Rail span | 10 m | 20 m | 20 m |

|

Grab type |

4-rope grab | 4-rope grab | 4-rope grab |

-

-

Classic case

-

•Customized solution: Excellent PLC program development ability that the customers can choose different controlling methods. The clients can choose dry fog dust

suppression or negative pressure dry dust removal system based on the conditions.

•Compact and less-maintenance structure: Lifting, closing and the rope trolley integrated together makes the structure more compact, less wear and light weight.

•Less maintenance: the excellent lubrication system leads to less maintenance.

•High efficiency and low noise: the parallel movement locus up-and-down means higher productivity without the rotation function.

•Leading brand of the electrical components: the electrical components are choosing from leading brand and can also be chose based on client's requirements.

•Compact and less-maintenance structure: Lifting, closing and the rope trolley integrated together makes the structure more compact, less wear and light weight.

•Less maintenance: the excellent lubrication system leads to less maintenance.

•High efficiency and low noise: the parallel movement locus up-and-down means higher productivity without the rotation function.

•Leading brand of the electrical components: the electrical components are choosing from leading brand and can also be chose based on client's requirements.

The GGU series grab ship unloader is often applied in bulk material discharging, which using the steel wire rope to control the grab to capture material and unload to the conveyor or trucks. With the high efficiency and wide usability, it is widespread used in bulk handling.

TOP