Heavy Duty Mechanical Seal for Slurry Processing Industries Technology

The Type 5860 heavy duty cartridge slurry seal is available as a single or double seal. It is designed to thrive in the harshest abrasive slurry environments. Process fluids such as ores, limestone, phosphates, kaolin clay, drilling mud,lime mud, coarse coal, boiler fly ash, rock salt, sludge,sand and gravel are no problem for the Type 5860.

Optimized together with slurry pump and mixer designs to meet your requirement for:

• Environmental Control

• Longest Operating Life

• Fault Free Installation

• Lowest Operating Cost

Applications

The Type 5860 Slurry Seals are rugged in construction, designed specifically for use in heavy duty slurry pumps, mixers and other rotating equipment throughout slurry processing industries:

• Ore Recovery

• Flue Gas Desulfurization (FGD)

• Phosphate Slurry

• Tailings Disposal

• Coal Slurry Transportation

• Wet Cement Processing

• Bauxite & Iron Ore Slurries

• Sand & Gravel

• Dewatering Systems

• Effluent Transport

• Waste Sludge Removal

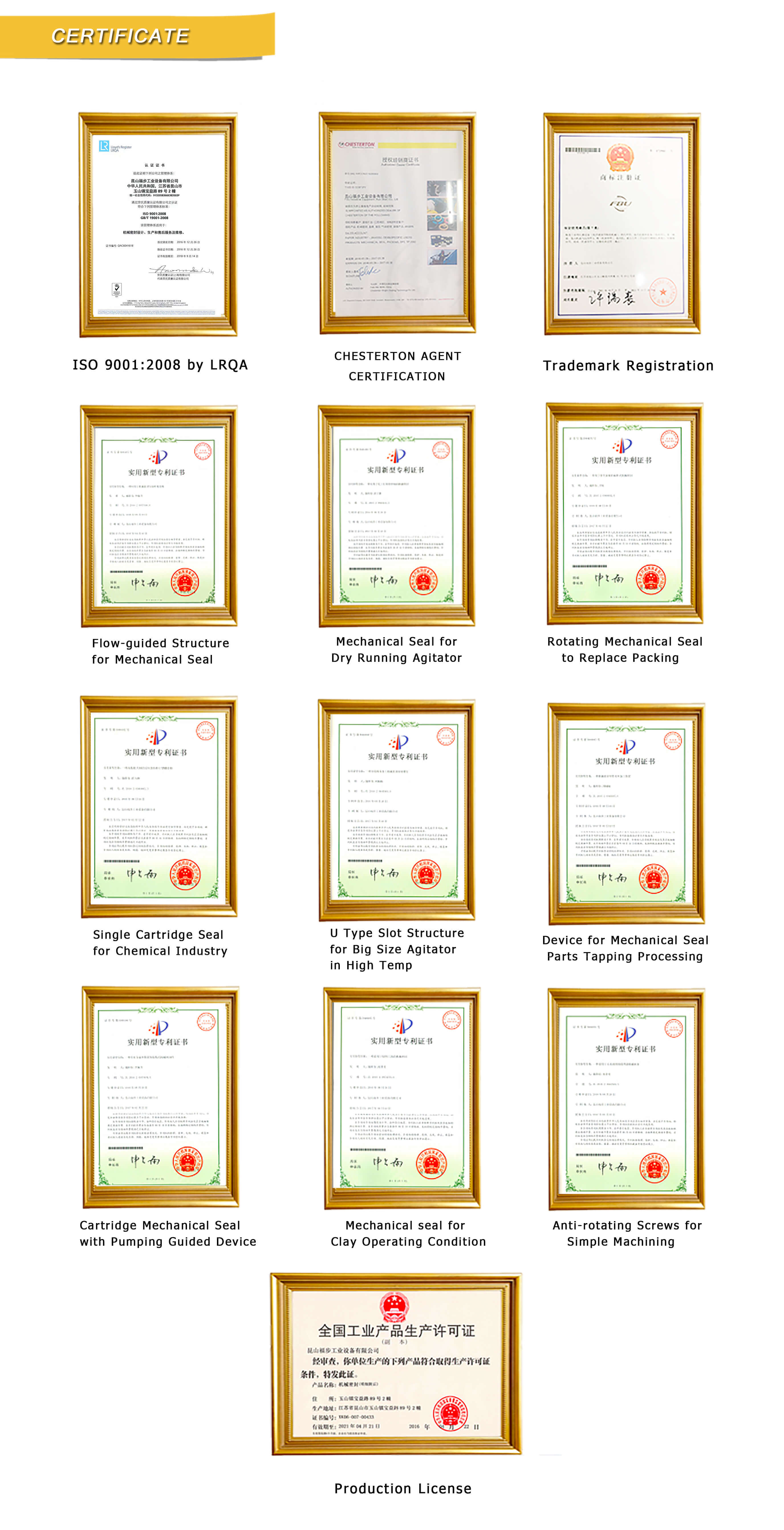

FBU was established in 2007, with FBU trademark and is constantly developing series of cartridge seals conforming to standards of ISO , ANSI, DIN, and API ,which are widely used in industry such as chemical processing, paper & pulp, Iron Mine, marine and food processing.

Our core business is cartridge mechanical seals and seal supporting system, FBU can design, manufacture, and recondition mechanical seals as per ISO 9001:2008 LRQA assessed management.

Choose FBU, find us to save your Time and Money.

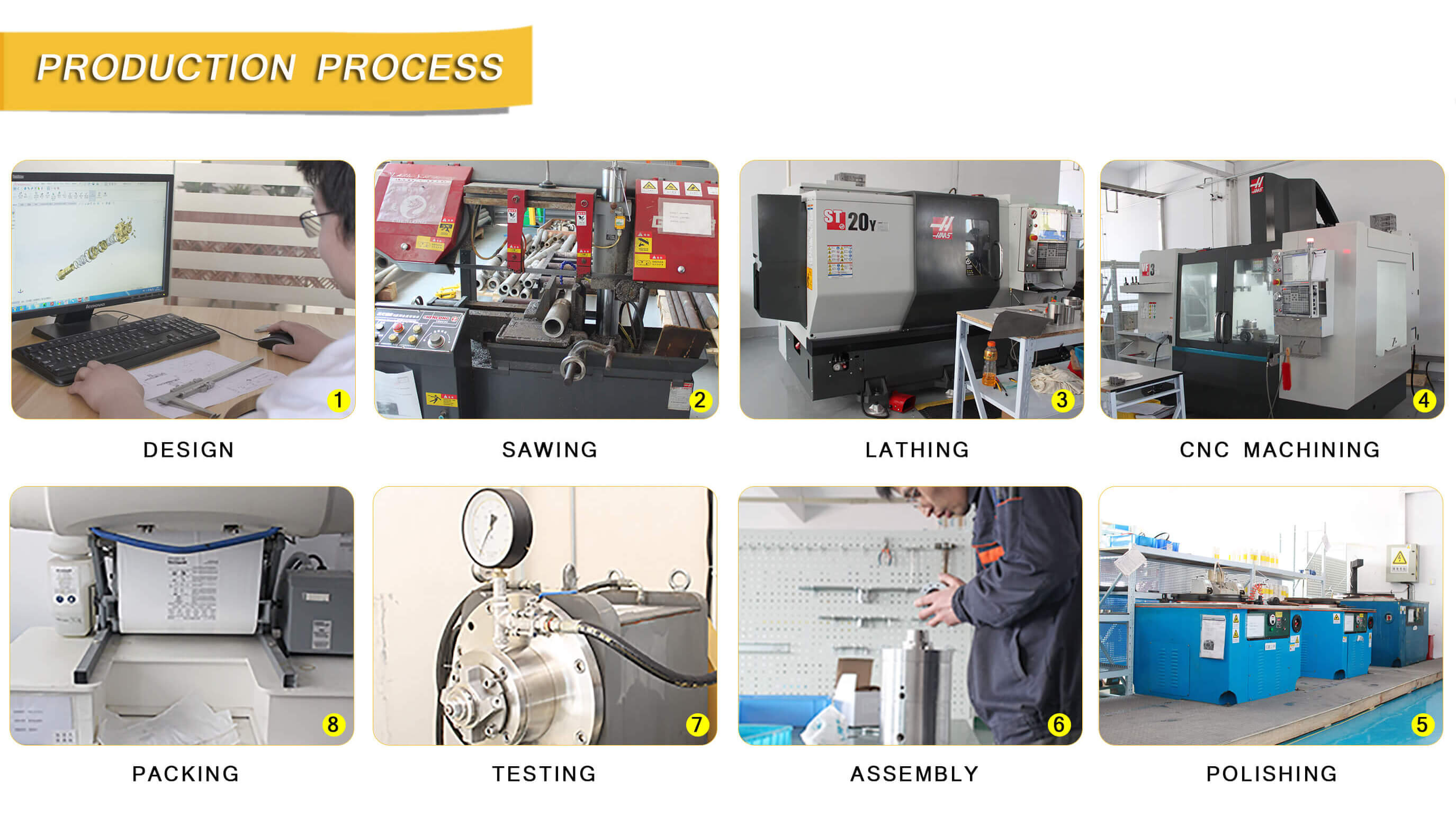

How we do our jobs ???

Want to know more about us, kindly feel at free to sale@fbuseals.com

| Materials of Construction | |

|---|---|

| Rotating Face: |

Sintered Silicon Carbide |

| Stationary Face: | Sintered Silicon Carbide |

| Elastomers: |

Viton® Standard |

| Aflas® or Kalrez ® | |

| Metal Parts: | 316 S.S. |

| Springs: |

316 S.S. |

| Operating Conditions | |

| Size: |

100mm |

| Temperature: | 150°C |

| Speed: | 3600 RPM |

| 2900 RPM | |

| 1800 RPM | |

| Pressure: | 25 BAR |

| Runout: | Up to .060 (1.5 mm) TIR |

| Radial movement | |

Want to know more about FBU, welcome to contact us at sale@fbuseals.com