The crushing capacity of this machine is larger than our competitors. It is stronger, able to withstand high compaction forces with a high output capacity ratio.

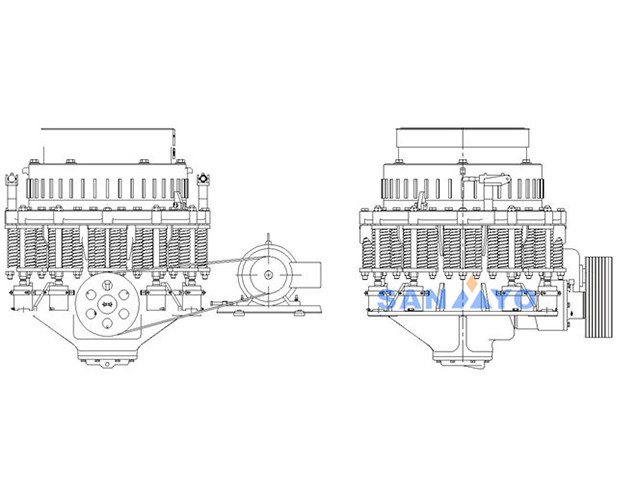

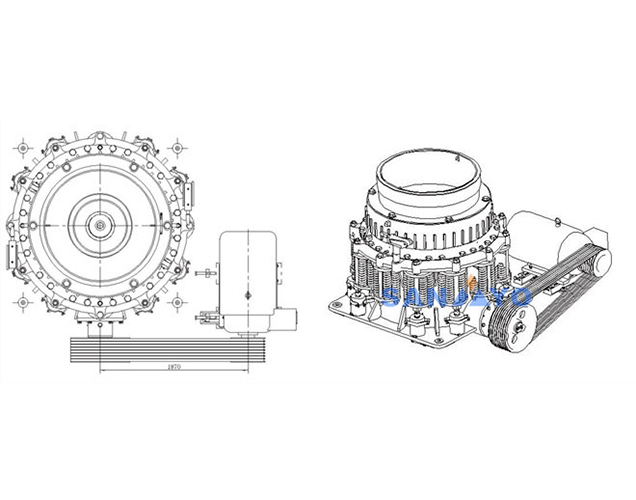

Sanyyo has designed this new Compound Cone Crusher by adopting advanced technical knowhow and combining it with practical production experience. This machine belongs to the new generation of crushers which supports the latest designs and is able to produce a large capacity of material, at an incredibly low cost which greatly increases returns on investment. Sanyyo has an advantage over our competitors as, we are able to manufacture complete crushing lines from primary, secondary and tertiary crushers, each with the capability of breaking different density materials to 5mm or finer. Our Compound Cone Crusher is commonly used in the iron ore industry, making Sanyyo a leader in our field!

Our Compound Cone Crushers are manufactured using internationally famous brand parts with high-quality cast steel components and premium spherical roller bearings to ensure stability and extended lifespan of the machine. Both spares and crushers are readily available, cost effective to run which results in lower production costs per ton.

2.An adjustable crusher which greatly increases output using the latest eccentric and spacing technology.

3.The Compound crushing chamber is able to produce cubic shaped product.

4.An extremely efficient machine which uses the laminating-crushing principle to decrease wear.

5.A hydraulic adjustment device makes this machine easy to operate.

6.Chamber clearing process can be completed within 10 minutes by using the hydraulic chamber clearing device.

7.Replacement of the inner movable cone has now been made easier with this use of this machine since, it is designed to eliminate the need of using complicated steps to free the main shaft. This new design now simplifies this process and greatly reduces maintenance time.

8.Sanyyo has adopted a dynamic sealing principal which illuminates the loss of oil, ensuring reliable running of the core assembly, prolonging the lifespan of this new generation machine.

9.Operating and monitoring systems have been improved to protect the machine from unnecessary and potential damage.

Sanyyo Compound Cone Crusher :

● Building material

● Cement material

● Metallurgy & Mining & Coal

● Chemical

● Refractory material

● Quartz & Glass raw material

● Artificial sandy soil

● Stone material plant

● Sand material plant

● Highway construction and so on

|

Model |

Chamber type |

Max feeding size (mm) |

Min discharge size (mm) |

Power (kw) |

Crushing capacity (t/h) |

Weight (kg) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

End discharge opening size (mm) |

|||||||||||||||

|

6 |

10 |

13 |

16 |

19 |

22 |

25 |

38 |

51 |

64 |

||||||

|

CC600 |

C |

95 |

10 |

37-45 |

|

20 |

25 |

30 |

35 |

45 |

50 |

76 |

|

|

5300 |

|

M |

72 |

6 |

37-45 |

18 |

20 |

25 |

30 |

35 |

40 |

45 |

60 |

|

|

5300 |

|

|

CC1000 |

C |

160 |

13 |

90-110 |

|

|

80 |

100 |

135 |

150 |

175 |

235 |

|

|

10800 |

|

M |

115 |

10 |

90-110 |

|

65 |

75 |

90 |

120 |

135 |

150 |

|

|

|

10800 |

|

|

F |

80 |

8 |

90-110 |

50 |

55 |

65 |

70 |

95 |

|

|

|

|

|

10510 |

|

|

EF |

50 |

6 |

90-110 |

50 |

55 |

65 |

70 |

102 |

|

|

|

|

|

10510 |

|

|

CC1160 |

C |

180 |

13 |

110-132 |

|

|

115 |

135 |

150 |

180 |

200 |

260 |

|

|

15500 |

|

M |

130 |

10 |

110-132 |

|

100 |

110 |

120 |

135 |

165 |

175 |

|

|

|

15500 |

|

|

F |

90 |

10 |

110-132 |

|

80 |

105 |

110 |

140 |

|

|

|

|

|

15500 |

|

|

EF |

60 |

6 |

110-132 |

60 |

74 |

105 |

110 |

130 |

|

|

|

|

|

15500 |

|

|

CC1300 |

C |

200 |

16 |

132-160 |

|

|

|

150 |

180 |

200 |

230 |

310 |

390 |

|

22300 |

|

M |

150 |

13 |

132-160 |

|

|

115 |

140 |

160 |

190 |

210 |

|

|

|

22300 |

|

|

F |

102 |

10 |

132-160 |

|

90 |

115 |

145 |

160 |

|

|

|

|

|

22300 |

|

|

EF |

70 |

8 |

132-160 |

|

88 |

110 |

135 |

155 |

|

|

|

|

|

22300 |

|

|

CC1380 |

C |

215 |

19 |

185-220 |

|

|

|

|

200 |

220 |

260 |

330 |

420 |

|

26300 |

|

M |

160 |

16 |

185-220 |

|

|

|

155 |

180 |

200 |

220 |

|

|

|

26300 |

|

|

F |

115 |

13 |

185-220 |

|

|

150 |

190 |

210 |

230 |

|

|

|

|

26300 |

|

|

EF |

76 |

8 |

185-220 |

|

122 |

148 |

185 |

200 |

|

|

|

|

|

26300 |

|

|

CC1500 |

C |

235 |

22 |

185-220 |

|

|

|

|

240 |

265 |

300 |

400 |

510 |

570 |

37750 |

|

M |

175 |

19 |

185-220 |

|

|

|

|

215 |

240 |

265 |

320 |

|

|

37750 |

|

|

F |

130 |

13 |

185-220 |

|

|

180 |

210 |

235 |

255 |

275 |

|

|

|

37750 |

|

|

EF |

90 |

10 |

185-220 |

|

148 |

178 |

200 |

220 |

|

|

|

|

|

37750 |

|

|

CC1680 |

C |

267 |

22 |

250-300 |

|

|

|

|

|

330 |

390 |

525 |

655 |

725 |

44300 |

|

M |

203 |

16 |

250-300 |

|

|

|

230 |

270 |

300 |

330 |

|

|

|

44300 |

|

|

F |

140 |

13 |

250-300 |

|

185 |

225 |

265 |

340 |

|

|

|

|

|

44300 |

|

|

EF |

95 |

10 |

250-300 |

|

180 |

220 |

260 |

335 |

|

|

|

|

|

44300 |

|

|

Electrical requirement |

380 to 420V, AC(50/60Hz) or according to local standard |

||||||||||||||

|

Temperature range |

-50℃ to 70℃ |

||||||||||||||

|

Lubricating system |

Auto control lubrication oil station, accident alert |

||||||||||||||

|

Protection system |

Oil system, One buttom to clean chamber |

||||||||||||||

|

Raw material water content |

≤20% |

||||||||||||||

|

Electric Control system |

ABB & Schneider, PLC |

||||||||||||||

|

Crush method |

Stone to stone crushing |

||||||||||||||