The product description

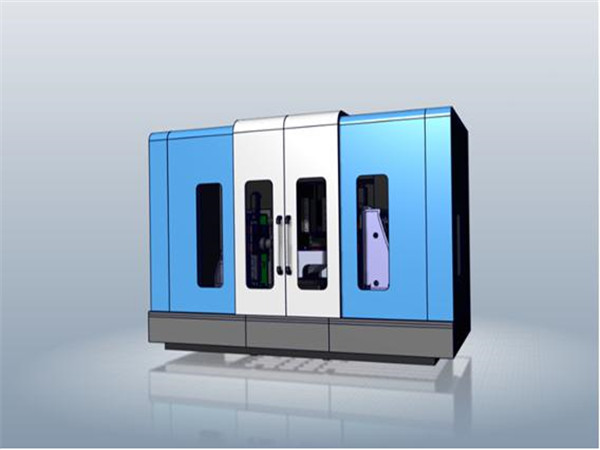

The machining center is designed for manufacturing automobile and locomotive parts with the compacted structure, high rigidity and high power of the spindle motor, which is applicable to be widely used in machining hard materials. The realization of intelligent production means milling, boring, drilling and tapping in continuous process while parts are clamped on the table one time. It features the shortened auxiliary time and the increased machining efficiency.

The overall structure

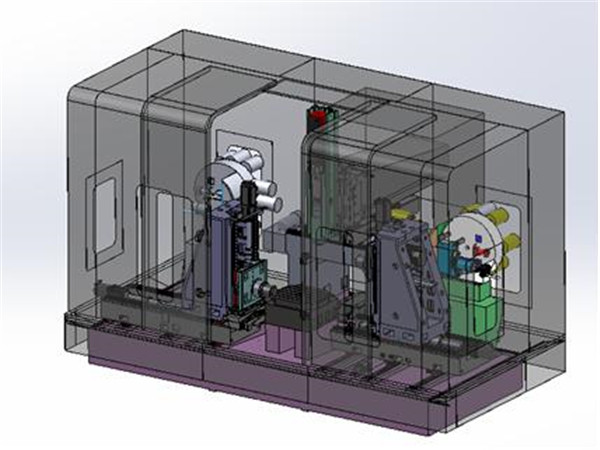

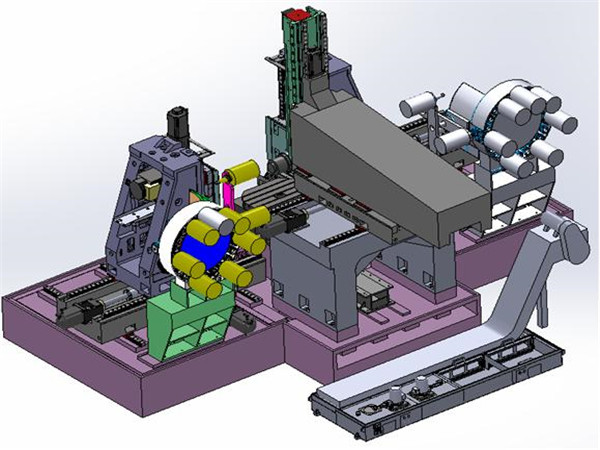

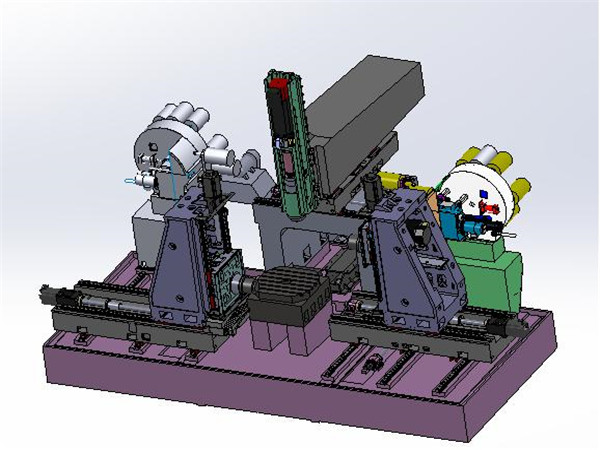

1)The compound machining center is composed of 2 sets of horizontal units, a set of vertical unit and a rotary square table. These units have a base (inverted T-shape) in common with vertical and horizontal tools magazine

2)Every unit is equipped with independent tool-exchange system.

3)It facilitates the chip removal with post-position chip conveyor.

4)SIEMENS 840D SL control system is used.

5)Every spindle is installed with BT-50, ZF gear box and center hole water cooling.

The performance characteristics

1)Linear motion of X,Y,Z axis are driven by three spindles. The integrated 3-axis machining is completed on the basis of the relation of the factors of workpieces.

2)In both vertical units, X and Y are installed with closed-loop control linear scale to ensure the relative position accuracy of synchronous machining.

|

UNIT |

PARAMETER |

||

|

1 |

Table size (L X W) |

mm |

800X800 |

|

VERTICAL SPINDLE |

|||

|

1 |

Spindle speed |

RPM |

6000 |

|

2 |

Spindle nose |

|

BT50 |

|

3 |

Spindle motor |

KW |

22 |

|

4 |

Double speed gear box |

|

1:1/1:4 |

|

5 |

KW |

7.7/7.7/7.7 |

|

|

6 |

Maximum output torque |

NM |

688 |

|

7 |

|

6312/6312/5010 |

|

|

8 |

3 axis guide rail form( X1 Y1 Z1) |

Overweight preloaded 55rollers |

|

|

9 |

Magazine capacity(Umbrella type) |

PCS |

24 |

|

10 |

3 axis travel (X1 Y1 Z1) |

MM |

950/650/500 |

|

11 |

Distance from spindle nose to table surface |

MM |

300-800 |

|

HORIZONTAL SPINDLE |

|||

|

1 |

Spindle speed |

RPM |

6000 |

|

2 |

Spindle nose |

|

BT50 |

|

3 |

Spindle motor |

KW |

22 |

|

4 |

Double speed gear box |

|

1:1/1:4 |

|

5 |

Maximum output torque |

NM |

688 |

|

6 |

7 axis servo motor X2 Y2 Z2, X3 Y3 Z3 B3 |

KW |

7.7/7.7/7.7 7.7/7.7/7.7/4.3 |

|

7 |

6 axis ball screw (X2 Y2 Z2,X3 Y3 Z3) |

|

6312/5010/6312 6312/5010/6312 |

|

8 |

6 axis guide rail form (X2 Y2 Z2,X3 Y3 Z3) |

Overweight preloaded 55rollers |

|

|

9 |

6 axis travel (X2 Y2 Z2,X3 Y3 Z3) |

|

800/600/600 |

|

10 |

Distance from spindle nose to table surface |

MM |

200-800 |

|

11 |

Distance from spindle center to table surface |

MM |

220-820 |

Key Components

|

ITEM |

DESCRIPTION |

BRAND |

MANUFACTURER |

|

1 |

Control system |

SINUMERIK 840D SL |

Germany |

|

2 |

Spindle unit |

Taiwan |

|

|

3 |

Spindle motor |

SINUMERIK 1PH8 |

Germany |

|

4 |

Spindle bearing |

FAG P4 |

Germany |

|

5 |

X,Y,Z (1) (2)(3)axis bearing |

NSK |

Japan |

|

6 |

Ball screw |

HIWIN |

Taiwan |

|

7 |

Main cylinder |

WAYLONG |

Taiwan |

|

8 |

Tool magazine |

JIFU |

Taiwan |

|

9 |

Automatic oiler |

BIJUR |

Sino-us joint venture |

|

10 |

Heat exchanger for electrical cabinet |

TONGFEI |

China |

|

11 |

Oil cooler |

TONGFEI |

China |

|

12 |

Chained chip conveyor |

HAILANGDE |

Sino-us joint venture |

|

13 |

Spindle center hole water cooling 30bar |

YALONG |

KOREA |

|

14 |

Electric component |

SCHNEIDER |

FRANCE |