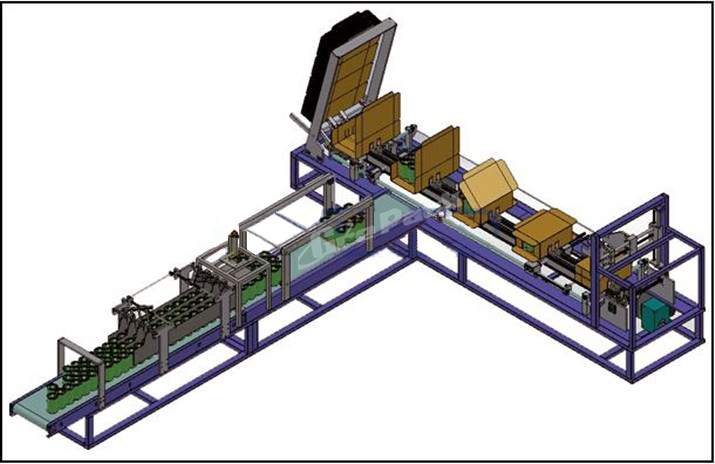

The automatic carton one-piece wrap machine is a new type of automatic packaging equipment independently researched and developed by our company on the basis of foreign advanced technology. And the packaging form that the machine can provide, compared with the traditional packaging methods, has a distinctive feature. At present, most of the domestically produced products, such as bottled, boxed, and block-packed products, are generally packaged in corrugated boxes.

This traditional packaging method has been accepted by the public. However, in addition to high-speed mass production of the beer industry, almost all medium and low-speed packaging areas, the carton packaging process is still the following production process: cardboard die-cutting → nail box → back cover → packing → sealing; using a carton wrap machine can Finished at once. Reduce the cost of equipment and equipment; greatly reduce the space occupied by equipment and raw materials and transportation conflicts at all levels; labor can be reduced by 7 to 9 people, labor management is more simplified;

the appearance quality of packaging is flat and beautiful; Contact, tight and firm after wrapping; cardboard material can be reduced by about 20%. The application of automatic wrap-around machine to reduce labor intensity, reduce labor resources, reduce production processes, and its comprehensive performance indicators and economic benefits are superior. It has been accepted and widely recognized by the society and will be an upgrade and inevitable development trend of traditional packaging methods.

2. There are many good protection features for packaged items. For example, moisture, heat, and easy handling.

3. Low transportation costs and easy mechanization and automation of packaging and transportation.

4. Specifications and size changes are easy to implement, and can quickly adapt to the packaging of various items.

5. It is convenient to seal and bundle, and it is easy to automate work.

6. It can adapt to the decoration printing of various types of cartons, which can solve the problem of product protection and promotion.

7. The waste bin is easy to recycle and reuse, and meets environmental protection requirements.

8. It can be greatly expanded by combining various coverings or moisture-proof materials.

9. The boxed box has a beautiful appearance, and the product grade and appearance image have been further improved.

10. Cost saving: Compared with manual cartons, it can save about 15% of the carton area, saving raw materials and reducing the cost of carton.

11. Saving labor: the paperboard, feeding, forming and pressing are all completed automatically. It completely replaces the cumbersome process of manual unpacking, manual packing, and sealing.

12. Use the hot-melt sealing box to replace the traditional sealing tape, which is environmentally friendly and hygienic, and the packaging product looks neat and beautiful.

It is used in the production equipment of beer, red wine, white wine, soy sauce, rice vinegar, tobacco rod, soap, floor, instant noodles, pickles, seasoning, eight-treasure porridge, milk powder, milk bricks, canned beverage production line, and complete the final packing process of the production line.

Model: 380V 50/60HZ 8KW Power: DC24V

Applicable carton: L200-350*W300-450*H100-300mm Air Pressure: 0.4Mpa

Speed: 12-15 carton/minute Glue Consumption: ≤4g/carton

Height: 800±50mm Temperature: 170℃±5℃

Air: 6-7kg 1.5S~2.5S

Dimension: 4300*2200*1900mm Weight: 2200kg

- Automatic Labeling Machine

- Automatic Filling Machine

- Form Fill Seal Pouch Packing Machine

- HFS premade pouch packing machine

- Vertical sachet packing machine

- Rotary Premade pouch packing machine

- Automatic Capping Machine

- Case & carton Erector Machine

- Case &carton Packing Machine

- Case & carton Sealing Machine

- Palletizer robot Machine

- Automatic Filling Line

- Pouch Packing line

- Other packing machine

- Selection Guide

- Turnkey Project