C & Z Purlin Roll Forming Line

5

Share

DESCRIPTION

1.We have different manufacture technologies for C&Z roll forming line. Following is the best technologies.

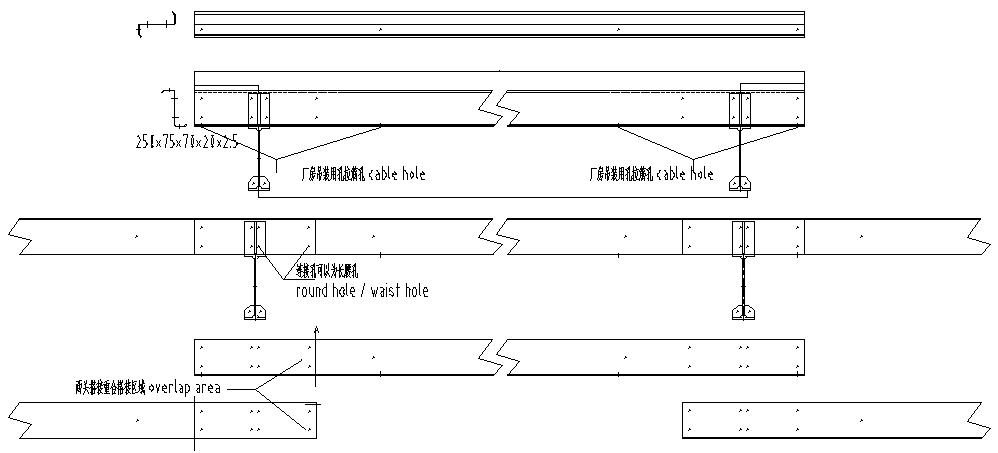

1)Punching all holes and cut to length after roll formed.

2)Characteristics of punching all holes and cut to length after roll formed:

A.The holes and length in longitudinal direction has high precision.

B.Save a lot of material.

C.The holes horizontal direction has high precision.

D.Can fit more bad of the strip steel (cold rolled steel strip).

E.It is easy to rectify the twist, arch bending & Lateral bending of purlin.

TECHNICAL PARAMETER

1)Punching all holes and cut to length after roll formed.

2)Characteristics of punching all holes and cut to length after roll formed:

A.The holes and length in longitudinal direction has high precision.

B.Save a lot of material.

C.The holes horizontal direction has high precision.

D.Can fit more bad of the strip steel (cold rolled steel strip).

E.It is easy to rectify the twist, arch bending & Lateral bending of purlin.

3)Experience has shown that our latest design which punching all holes and cut to length after roll formed is the best way to make sure the purlin has good quality.

2.The introduction of product design characteristics

2.1 Decoiler: The cantilever style.

2.2 Adopt two rollers for pinching & five rollers for leveling

2.3 Feeding guide stand type:side trolley type

2.4 Screw guide rail, screw guide with high precision ball screw and linear guide rail, the precision of the leadscrew rail is 0.02 mm, degree of hardness of HRC60

2.5 Screw transversal, the guide rail is generally used in machine tool machining center machine tool, now in the cold bending steel on its precision can satisfy completely.

1.Steel coil material: Q235MC – σs=235Mpa

2.Outline of main roll forming: 7M X 2M

3.Outline of installation area: 35MX2M

4.Diameter of roller shaft: ¢70㎜

5.Material of shaft: 42CrMo

6.Hardness of shaft: HRC30°

7.Yield strength of shaft:930 Mpa

8.Tensile strength of shaft:1080 Mpa

9.Diameter of ball screw: 40mm

10.Thickness of coil: 1.5mm-3mm

11.Manual de-coiler: passive de-coiling, manual up tight

12.De-coiler capacity: 4T

13.Frame: steel structure welding parts, high temperature tempering to stress after welding

14.The frame surface coating: shot blast

15.Frame precision guarantee: pentahedron processing

16.Memorial arch bearing: locating surface using axial thrust bearing, to prevent the roller series

17.Pinching motor: 3KW

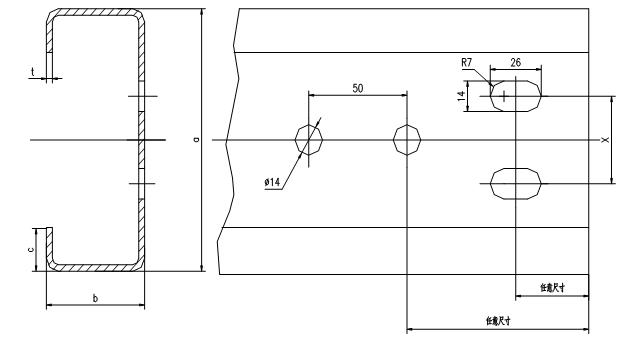

18.Punching mould: 3 sets

19.Stand type: WHPF45

20.Chain type: 20A-double row

21.Produce speed: 0-12m/min

22.Roller stand: 11 station

23.Length of roller stand: 635mm

24.Hydraulic station motor power: 30kw

25.Pump: gear pump

26.Material of roller adopts high-quality alloyed bearing steel GCR15

27.Quenching hardness of roller: HRC580-600

28.Cutter: adjustable cutter

29.Material of blade: Cr12 MoV

30.Heat treatment of cutting blade: (HRC58°-62°)

31.The shear tolerance: ±2mm

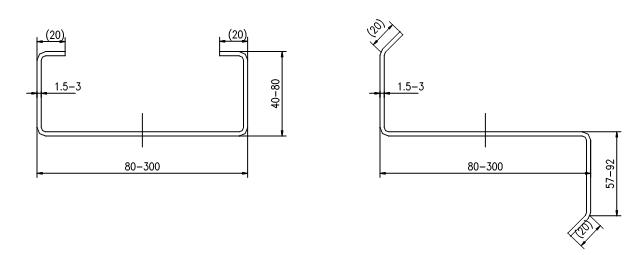

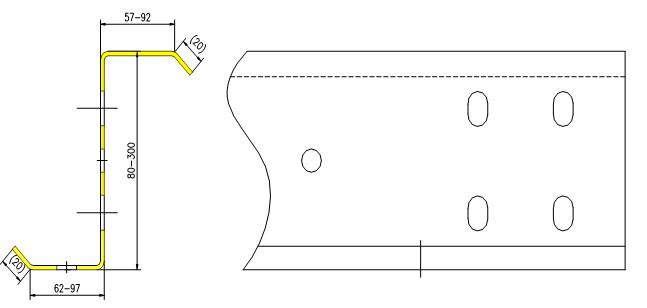

PURLIN SERIES

APPLICATION

2.Outline of main roll forming: 7M X 2M

3.Outline of installation area: 35MX2M

4.Diameter of roller shaft: ¢70㎜

5.Material of shaft: 42CrMo

6.Hardness of shaft: HRC30°

7.Yield strength of shaft:930 Mpa

8.Tensile strength of shaft:1080 Mpa

9.Diameter of ball screw: 40mm

10.Thickness of coil: 1.5mm-3mm

11.Manual de-coiler: passive de-coiling, manual up tight

12.De-coiler capacity: 4T

13.Frame: steel structure welding parts, high temperature tempering to stress after welding

14.The frame surface coating: shot blast

15.Frame precision guarantee: pentahedron processing

16.Memorial arch bearing: locating surface using axial thrust bearing, to prevent the roller series

17.Pinching motor: 3KW

18.Punching mould: 3 sets

19.Stand type: WHPF45

20.Chain type: 20A-double row

21.Produce speed: 0-12m/min

22.Roller stand: 11 station

23.Length of roller stand: 635mm

24.Hydraulic station motor power: 30kw

25.Pump: gear pump

26.Material of roller adopts high-quality alloyed bearing steel GCR15

27.Quenching hardness of roller: HRC580-600

28.Cutter: adjustable cutter

29.Material of blade: Cr12 MoV

30.Heat treatment of cutting blade: (HRC58°-62°)

31.The shear tolerance: ±2mm

Products

- Continuous Sandwich Panel Production Line

- Discontinuous Sandwich Panel Production Iine

-

Roll Forming Machine

- Roof & Wall & Door Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Downpipe Roll Forming Machine

- Box Beam Roll Forming Machine

- Folding, Shearing & Bending Machines

- Steel Springboard Roll Forming Machine

- Steel Sheet Pile Roll Forming Machine

- No-girder And Columniation Curve Roll Forming Machine

- Slitting & Cut to length line

- PU Raw Material

TOP