Backwashing Automatic Filter Housing System BCM Series

4

Share

Feature

Full automatic self cleaning filter housing system

Full automatic back washing filter housing BCM series

BCM full automatic back washing filter housing is suitable for filtering high flow, high speed, low viscosity fluid particle impurity.

BCM full automatic back washing filter housing is a mechanical and electrical products, with advantages of reasonable design, high filtration efficiency, low operating costs, continuous filtration in back washing process, etc., which is widely used in metallurgy, chemical, electric power, oilfield injection water, ballast water, environment-friendly water treatment, etc..

Working principle of BCM full automatic back washing filter housing:

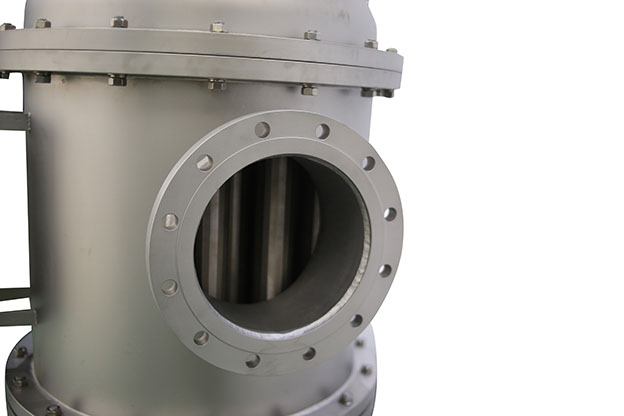

The filtered liquid is flowing from the inlet to the filter housing, then going through the fixing plate into the filter housing, the liquid flows from the filter element inside to the outside, and then flows out from the filter vessel outlet; Impurities produced from back washing filter flows out from the sewage outfall.

How it works?

When liquid flows through the filter element, the solid particles will be trapped in the inner side of the filter element. With the increase of pollutants, the differential pressure between the contaminated side and the clean side of the filter is gradually increasing. When the differential pressure reaches the set value, the differential pressure meter sends a message and the filter housing starts automatic back washing process.

back washing process:

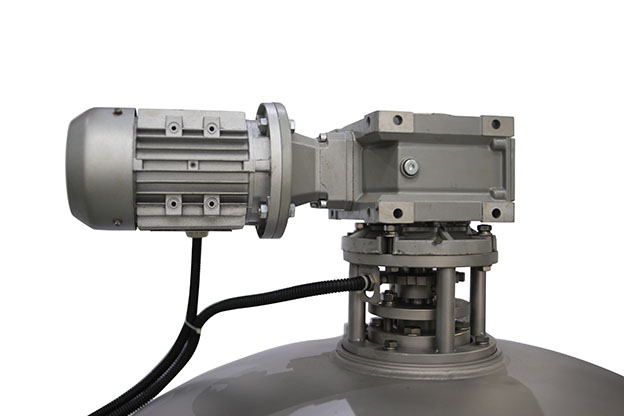

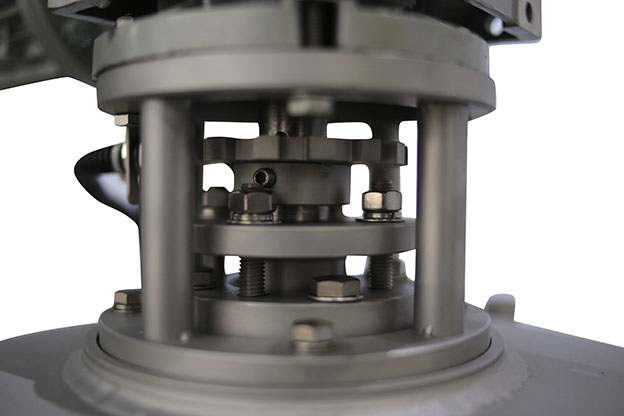

1.Gear motor drives washing arm to turn round by the jackshaft, the rotation angle of the washing arm is controlled by a photoelectric positioning switch, which will make it align to the cleaned filter.

2.The drain valve is opened, so that differential pressure will form between the filter element of the outside (clean side) and pollutant drainage.

3.Under the action of pressure difference, liquid flow of the clean side will flows from cleaned filter outside to inside to carry out back washing process, pollutants accumulated in the inner side of the filter screen will be washed away and flow out the filter through the sewage outfall.

4.The back washing time of each filter elment has been set, so when the back washing time is reached, the pollution discharge valve will be close, and this back washing process of filter element is over, then gear motor will drive washing arm to turn again, conducting back washing to the next set of filters, sewage valve will be open again., and so on to conduct back washing process to each mesh.

5.After all filter cleaning is completed, the washing arm returns to the original position under the control of the photoelectric switch, which means a back washing cycle is end.

6.Because the back washing is washing a set of filters in turn, therefore during the process the filter can maintain a continuous fluid filtration state.

Set back washing process:

1.Differential pressure setting: the filter has differential pressure gauge, which is used to set filter differential pressure.

2.Time setting: the control box has time setting device, which can be used to set back washing process cycle according to user requirements. Differential pressure setting and time setting are automatic back washing configuration process, the two settings exist at the same time, while pressure setting is prior.

3.Manual start: In addition to differential pressure setting and time setting automatic back washing process, there is also TEST key to manually start the process, which is used for debugging and maintenance.

Design features of BCM full automatic back washing filter housing:

1.The internal mechanical structure of filtration equipment using patented technology, realizes the back washing function in true sense, which can completely remove the filter impurities, clean every corner without dead angle, flux without attenuation, and guarantee the filtration efficiency and long service life.

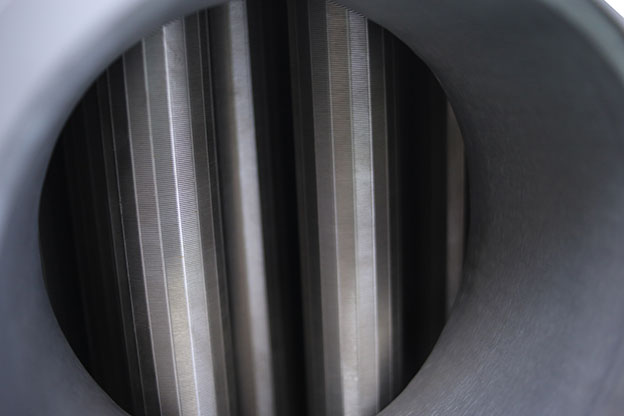

2.Filter equipment selects 304, 316L, 2205, MONEL materials wedge filter element, with advantages of large intensity, high precision, corrosion resistance, and the maximum filtering accuracy is up to 25 microns.

3.Through its own retrieval and strain function, filtering equipment could realize automatic back washing, and can deal with unstable water quality fluctuation without manual intervention.

4.Filter equipment control system is sensitive, accurate operation, and can flexibly adjust the differential pressure and time setting value of back washing based on different water and filter accuracy.

5.During the back washing process, each filter vessel is conducted back washing in turn; which ensures the filter screen safety, efficient cleaning, while other filters are not affected and continue to be filtered.

6.Filtering equipment have less vulnerable parts, no consumable material, with low operating and maintenance costs and easy operation and management.

7.The filter equipment is designed compact and reasonable, with a small size, which is flexible and convenient for installation and movement.

8.Filtration equipment uses pneumatic drain valve, with a short time of back washing process, less water consumption, environmental protection and economic.

9.Filtering equipment working state is displayed by the touch screen, and the differential pressure and time setting is convenient for view.

Application area:

Sea water desalination, circulating cooling water and oilfield reinjection water, ballast water for ship, boiler reuse water, Ultrafiltration back osmosis filtration, ion exchange pretreatment, Paper nozzle filter.

Design Parameter Table

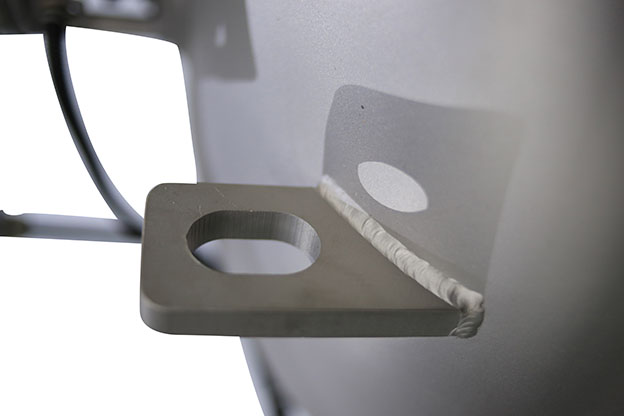

Photos

Full automatic self cleaning filter housing system

Full automatic back washing filter housing BCM series

BCM full automatic back washing filter housing is suitable for filtering high flow, high speed, low viscosity fluid particle impurity.

BCM full automatic back washing filter housing is a mechanical and electrical products, with advantages of reasonable design, high filtration efficiency, low operating costs, continuous filtration in back washing process, etc., which is widely used in metallurgy, chemical, electric power, oilfield injection water, ballast water, environment-friendly water treatment, etc..

Working principle of BCM full automatic back washing filter housing:

The filtered liquid is flowing from the inlet to the filter housing, then going through the fixing plate into the filter housing, the liquid flows from the filter element inside to the outside, and then flows out from the filter vessel outlet; Impurities produced from back washing filter flows out from the sewage outfall.

How it works?

When liquid flows through the filter element, the solid particles will be trapped in the inner side of the filter element. With the increase of pollutants, the differential pressure between the contaminated side and the clean side of the filter is gradually increasing. When the differential pressure reaches the set value, the differential pressure meter sends a message and the filter housing starts automatic back washing process.

back washing process:

1.Gear motor drives washing arm to turn round by the jackshaft, the rotation angle of the washing arm is controlled by a photoelectric positioning switch, which will make it align to the cleaned filter.

2.The drain valve is opened, so that differential pressure will form between the filter element of the outside (clean side) and pollutant drainage.

3.Under the action of pressure difference, liquid flow of the clean side will flows from cleaned filter outside to inside to carry out back washing process, pollutants accumulated in the inner side of the filter screen will be washed away and flow out the filter through the sewage outfall.

4.The back washing time of each filter elment has been set, so when the back washing time is reached, the pollution discharge valve will be close, and this back washing process of filter element is over, then gear motor will drive washing arm to turn again, conducting back washing to the next set of filters, sewage valve will be open again., and so on to conduct back washing process to each mesh.

5.After all filter cleaning is completed, the washing arm returns to the original position under the control of the photoelectric switch, which means a back washing cycle is end.

6.Because the back washing is washing a set of filters in turn, therefore during the process the filter can maintain a continuous fluid filtration state.

Set back washing process:

1.Differential pressure setting: the filter has differential pressure gauge, which is used to set filter differential pressure.

2.Time setting: the control box has time setting device, which can be used to set back washing process cycle according to user requirements. Differential pressure setting and time setting are automatic back washing configuration process, the two settings exist at the same time, while pressure setting is prior.

3.Manual start: In addition to differential pressure setting and time setting automatic back washing process, there is also TEST key to manually start the process, which is used for debugging and maintenance.

Design features of BCM full automatic back washing filter housing:

1.The internal mechanical structure of filtration equipment using patented technology, realizes the back washing function in true sense, which can completely remove the filter impurities, clean every corner without dead angle, flux without attenuation, and guarantee the filtration efficiency and long service life.

2.Filter equipment selects 304, 316L, 2205, MONEL materials wedge filter element, with advantages of large intensity, high precision, corrosion resistance, and the maximum filtering accuracy is up to 25 microns.

3.Through its own retrieval and strain function, filtering equipment could realize automatic back washing, and can deal with unstable water quality fluctuation without manual intervention.

4.Filter equipment control system is sensitive, accurate operation, and can flexibly adjust the differential pressure and time setting value of back washing based on different water and filter accuracy.

5.During the back washing process, each filter vessel is conducted back washing in turn; which ensures the filter screen safety, efficient cleaning, while other filters are not affected and continue to be filtered.

6.Filtering equipment have less vulnerable parts, no consumable material, with low operating and maintenance costs and easy operation and management.

7.The filter equipment is designed compact and reasonable, with a small size, which is flexible and convenient for installation and movement.

8.Filtration equipment uses pneumatic drain valve, with a short time of back washing process, less water consumption, environmental protection and economic.

9.Filtering equipment working state is displayed by the touch screen, and the differential pressure and time setting is convenient for view.

Application area:

Sea water desalination, circulating cooling water and oilfield reinjection water, ballast water for ship, boiler reuse water, Ultrafiltration back osmosis filtration, ion exchange pretreatment, Paper nozzle filter.

| Design Parameter Table | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| NAME: Full automatic back washing filter housing BCM series | |||||||||

| MODEL: BCM300F100EDB | |||||||||

|

Design Data |

Code&STD. |

Reference GB150.1~150.4-2011《Pressure Vessels》 |

|||||||

|

Design Press. |

(Mpa.g) | 1.0 |

Mat'of Man Parts |

|

S30408 (GB 24511-2009) |

||||

|

Design Temp. |

(℃) | 80 |

Corr.Allow. |

(mm) | 0 | ||||

|

Hydro. Test Press. |

(Mpa.g) | 1.25 |

Filter Element Material |

|

SS 304 | ||||

|

Filte Area. |

(㎡) | 0.81 |

Gasket Material |

|

NBR | ||||

|

No. Filter Element |

|

7 |

Full Capacity |

(m³) | 0.06 | ||||

|

Filter Element Size |

(mm) | CartridgeΦ70*580 |

Empty Weight |

(kg) | ~120 | ||||

|

Clean Pr.Drop |

Mpa | 0.01 |

Max.Allowed Pr.Drop |

Mpa | 0.1 | ||||

|

Technical Data |

According to the user data tables or after consultation to fill in |

||||||||

|

Flow Rate. |

(m³/h) | / |

Fluid. |

|

/ | ||||

|

Working Temp.(in/out) |

(℃) | / |

Fluid Performance |

|

/ | ||||

|

Working Press. |

(Mpa.g) | / |

Fluid Density |

(kg/m³) | / | ||||

|

Pore Size. |

(μm) | / |

Viscosity |

(cp) | / | ||||

|

Solid Content. |

(WT%) | / |

|

|

|

||||

| NOZZLE LIST | |||||||||

|

Mark |

Size |

PN |

Connections Standard |

Flange Type |

Face Type |

Service |

From q |

||

| N1 | DN100 | 10 | HG/T20592-2009 | PL | RF | Inlet |

|

||

| N2 | DN100 | 10 | HG/T20592-2009 | PL | RF | Outlet |

|

||

| N3 | DN40 | 10 | HG/T20592-2009 | PL | RF | Drain |

|

||

| N4 | 1/2" | / | Rc1/2"(male) | / | / | Vent |

|

||

| N5 | 1/4" | / | Rc1/4"(female) | / | / |

Pressure Guage |

|

||

| N6 | 1" | / | R1"(male) | / | / | Drain |

|

||

| P1、P2 | 1/4" | / | Rc1/4"(female) | / | / |

Differential pressure |

|

||

TOP