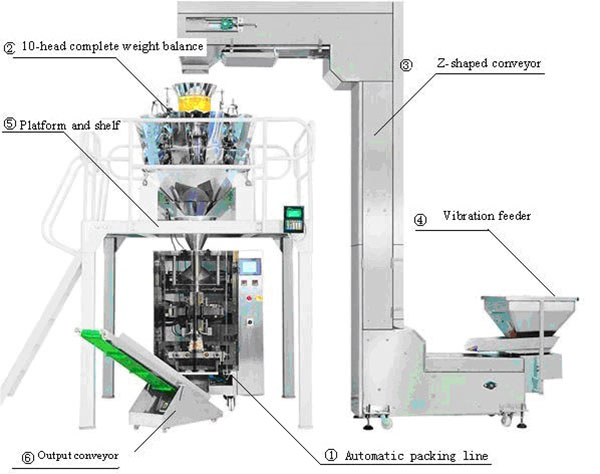

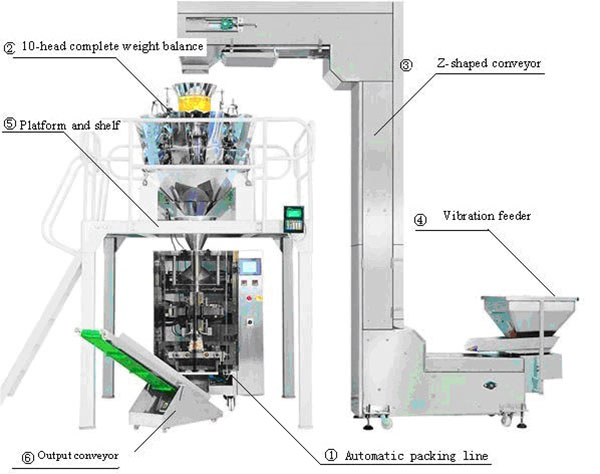

Automatic Multifunctional Packing Machine

44

Share

Details

Overview:

Using temperature controller to keep temperature of hot seal unaltered to use dent form sealer to seal film highly series is equipped with automatic trouble alert to find product to be cut by knife, door not to be closed, film wrapping not to run exactly and film to be used up ect.

Main Technical Specifications:

Function and Characteristics:

Option:

Applications:

It is suitable to use in the quantitative packing granular materials, such as washing powder, monosodium glutamate, chicken essence, salt, rice, seed. or a little bigger granules like pills, tablets, capsules, candies, nuts, peanuts, agricultural products, dry fruits, beef jerky, etc; or some sliced, blocked and puffed foods like potato slices, potato chips, rice crust, etc.

Characteristic:

Specifications

This bag packing machine using Japan PLC programmer and display screen, which is easy to predominate running state, trouble state, operation order, and production state. Using AC Alternating Current servo motor to control film pulling. In the cause of film pulling it is stable, and with high accuracy orientation. Lubricating is not needed it is possible to revise parameter and adjust position without stopping the machine.

Using temperature controller to keep temperature of hot seal unaltered to use dent form sealer to seal film highly series is equipped with automatic trouble alert to find product to be cut by knife, door not to be closed, film wrapping not to run exactly and film to be used up ect.

Main Technical Specifications:

| PXP-280 | |

| Sealing mode | 3 sides seal/4 sides seal/centre sealing |

| Packing speed | 25-60bags/min |

| Bag size | L:100-1000mm |

| W:120-500mm | |

| Filling quantity | 100-5000g |

| Power | 220v 50Hz 1.5kw |

| Machine weight | 350kg |

| Dimension | 600*790*1800mm |

Function and Characteristics:

1. Safety device: Machine stop at abnormal air pressure, heater disconnection alarm。

2. It matchs with the glass safety door. The machine will stop working when you open the door. So that it could protect the safety of operators. At the same time, it could prevent dust.

3. Use the plastic bearing, don’t need put on oil, less pollution.

4. The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

5. Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food

6. The part where touch to the material is made of stainless steel is accord with the request of GMP.

7. The canning mete and career can be accommodated, it is accurate.

8. The canning cobbra of the machine use the setting of defending leak and drawbench.

Option:

Gas flushing (Air or Nitrogen gas)、Tear notch 、Gusseted device、Air expeller、Hole punch device 、Polyethylene sealing system

Multifunction weigher machine:

Multifunction weigher machine:

Applications:

It is suitable to use in the quantitative packing granular materials, such as washing powder, monosodium glutamate, chicken essence, salt, rice, seed. or a little bigger granules like pills, tablets, capsules, candies, nuts, peanuts, agricultural products, dry fruits, beef jerky, etc; or some sliced, blocked and puffed foods like potato slices, potato chips, rice crust, etc.

Characteristic:

Vibration feed

Scale measurement, bagging Artificially-- Packaging specifications filling range, two scales in turn Cutting;

Packaging specifications>filling range, two scales cutting together, the filling accuracy is no relationship with the proportion of the material--Packaging specifications is Adjustable

Movable mask, event-type scale fighting, the card-fit-type splice mouth

RS485 Computer networking, serial interface

Dust-type splice mouth, mixing motor

Main Technical Specifications:

| Model | PXP Multi-head weigher machine |

| Filling range (g) | 100-5000 |

| Packaging specifications(g) | 100-5kg |

| Singular Error(g) | ≤±4 |

| Packing speed(bag/min) | 5-80 bas per minute(customized) |

| Bag size | L80-300mm, W50-200mm(customized) |

| Control system | PLC+ touch screen |

| material | stainless steel |

| Pneumatic | 0.65Mpa,0.3cbm/min |

| voltage | 380V, 50Hz,3P/ 220V, 60Hz, 3P |

| Weight | G.W.1000kg |

| Dimension | about 5*2*3.5m for the whole packing line |

| Power | 2.5KW |

| Film material |

Paper/polyethylene; cellophane/polyethylene; Plated aluminum/polyethylene; BOPP/polyethylene; nylon/polyethylene |

| supplies | all kinds of grain or granule, such as sugar, salt, coffee, seasoning, instant powder drinks, desiccant, washing powder, etc; or a little bigger granules like pills, tablets, capsules, candies, nuts, peanuts, agricultural products, etc; or some sliced, blocked and puffed foods like potato slices, potato chips, rice crust, etc. |

| Main functions | Automatically measure, make bags, fill, seal, cut and print codes. |

TOP