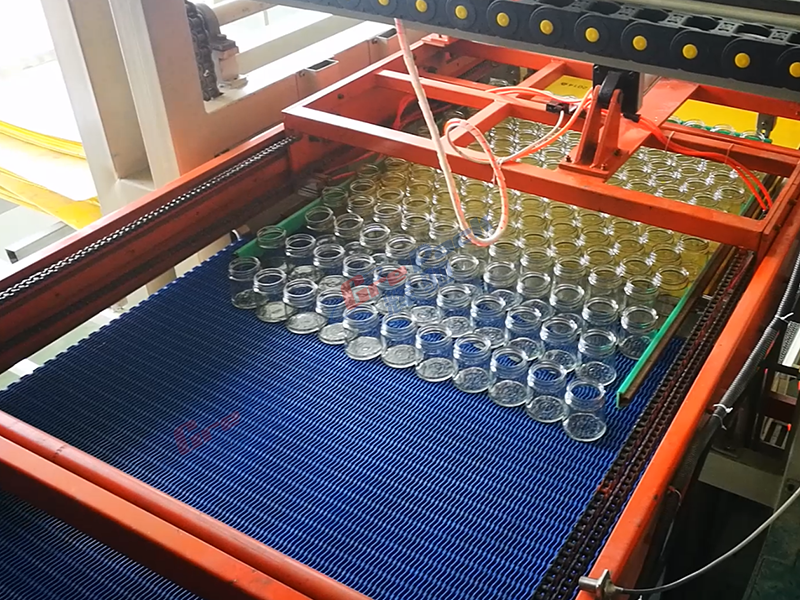

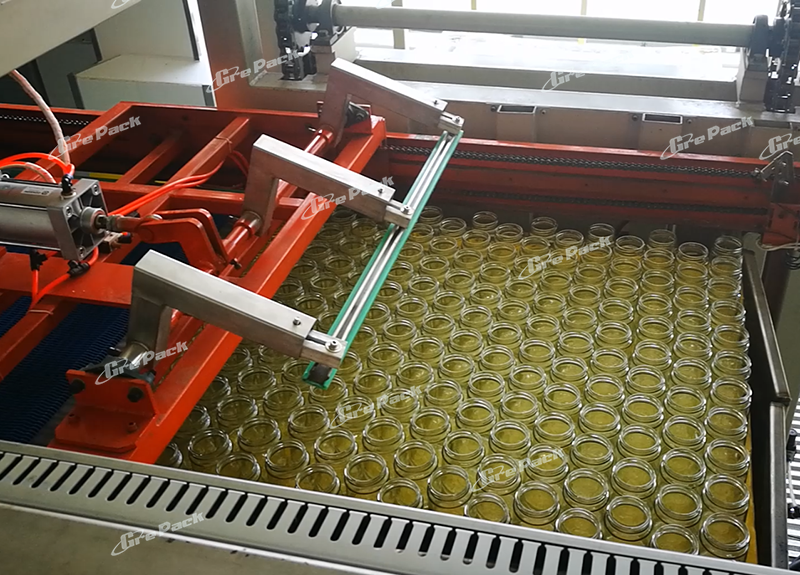

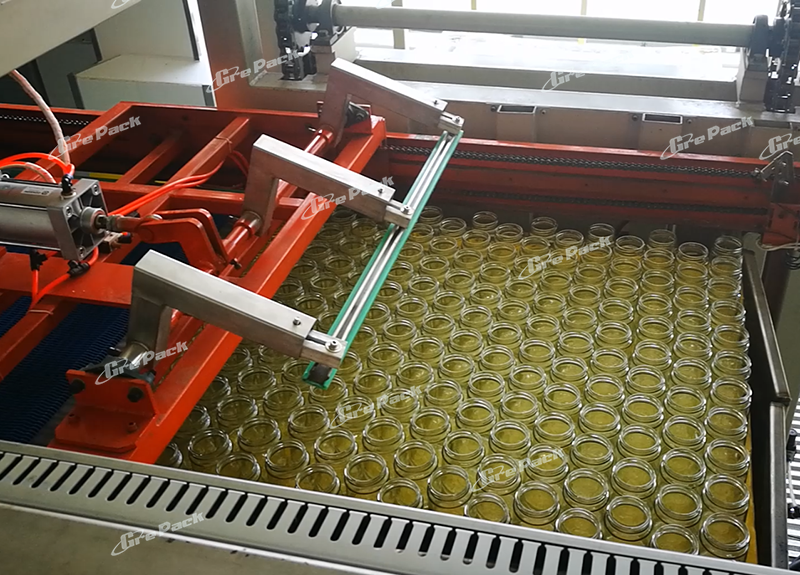

Automatic low position tin & bottles & jar palletizer

1

Share

Equipment features

Using pneumatic components and cylinders produced by Taiwan Airtac, the quality and performance are reliable.

The safety door and the cover are provided with electrical induction devices. When the cover door is opened, the machine stops working and the operators can be protected.

The stacking method is easy and simple to adjust, and can be performed on the touch screen.

The pallet library has a large capacity and can accommodate 10-12 empty pallets, which can realize automatic supply of pallets.

The noise is small and meets the international standard of China, and the noise is below 75db.

Several stacking methods can be completed without replacing the stacking parts.

Equipment composition

The palletizer is to put the cartons, barrels, bags, etc., which have been loaded into the container, on a pallet according to a certain arrangement code.,automatically having layers of pelletizes, then launch for a convenient fork working to warehouse.the machine adopt PLC + touch screen control, realizing an Intelligent and easy operation. It can largely induce the labor intensity.

Using pneumatic components and cylinders produced by Taiwan Airtac, the quality and performance are reliable.

The safety door and the cover are provided with electrical induction devices. When the cover door is opened, the machine stops working and the operators can be protected.

The stacking method is easy and simple to adjust, and can be performed on the touch screen.

Stacking is stable and efficient, which can save manpower.

The pallet library has a large capacity and can accommodate 10-12 empty pallets, which can realize automatic supply of pallets.

The noise is small and meets the international standard of China, and the noise is below 75db.

Several stacking methods can be completed without replacing the stacking parts.

Carton load in, sorting device.

Lifting and palletizing device.

pallet stacking and automatic supply device

Real discharge device

Working process

Lifting and palletizing device.

pallet stacking and automatic supply device

Real discharge device

Carton feeding part:

①carton conveying device

According to the set arrangement, the carton is forced to be turned or conveyed to achieve arranging and sorting

②sorting device:

The supply conveyor belt pushes the arranged first row of cartons into the lifting device with the cylinders, and then pushes them into the second column and the third column in order to form a sorting layer.

Automatic palletizing device:

When the carton is formed into a group (layer) in a certain order, the elevator carries the sorting layer up and moves forward to the upper part of the palletizing device, and is smoothly placed on the pallet (or the previous sorting layer) to form an automatic palletizing. . The palletizing device relies on a variable frequency motor and a chain to complete its ascending, descending and advancing (retracting).

Pallet part:

①pallet supplying device

The pallet library can stack 8-10 empty pallets and supply pallets to the palletizing device at regular timing. Powered by a separate motor.

②pallet conveying device

When a pallet reaches the number of pallets and sends a signal, it will push out the palletizing part. The actual delivery is delivered to the designated location by removing the conveyor belt.

Parameter

①carton conveying device

According to the set arrangement, the carton is forced to be turned or conveyed to achieve arranging and sorting

②sorting device:

The supply conveyor belt pushes the arranged first row of cartons into the lifting device with the cylinders, and then pushes them into the second column and the third column in order to form a sorting layer.

Automatic palletizing device:

When the carton is formed into a group (layer) in a certain order, the elevator carries the sorting layer up and moves forward to the upper part of the palletizing device, and is smoothly placed on the pallet (or the previous sorting layer) to form an automatic palletizing. . The palletizing device relies on a variable frequency motor and a chain to complete its ascending, descending and advancing (retracting).

Pallet part:

①pallet supplying device

The pallet library can stack 8-10 empty pallets and supply pallets to the palletizing device at regular timing. Powered by a separate motor.

②pallet conveying device

When a pallet reaches the number of pallets and sends a signal, it will push out the palletizing part. The actual delivery is delivered to the designated location by removing the conveyor belt.

Type: HC-MD01

Power: AC,3 Phase 380V,9KW 50HZ

Application: bottle/carton/bag/bucket

Apply To Pallet: L1000-1200mm*W1000-1200

Pallet speed: Single tunnel 15-25 carton/m;

Double tunnel 20-40carton/m

Air Pressure: 500NL/MIN(air consumption:5-6kg/cm2)

Dimension: 7300mm*4500mm*3700mm

weight: 6000kg

Power: AC,3 Phase 380V,9KW 50HZ

Application: bottle/carton/bag/bucket

Apply To Pallet: L1000-1200mm*W1000-1200

Pallet speed: Single tunnel 15-25 carton/m;

Double tunnel 20-40carton/m

Air Pressure: 500NL/MIN(air consumption:5-6kg/cm2)

Dimension: 7300mm*4500mm*3700mm

weight: 6000kg

Products

- Automatic Labeling Machine

- Automatic Filling Machine

- Form Fill Seal Pouch Packing Machine

- HFS premade pouch packing machine

- Vertical sachet packing machine

- Rotary Premade pouch packing machine

- Automatic Capping Machine

- Case & carton Erector Machine

- Case &carton Packing Machine

- Case & carton Sealing Machine

- Palletizer robot Machine

- Automatic Filling Line

- Pouch Packing line

- Other packing machine

- Selection Guide

- Turnkey Project

TOP