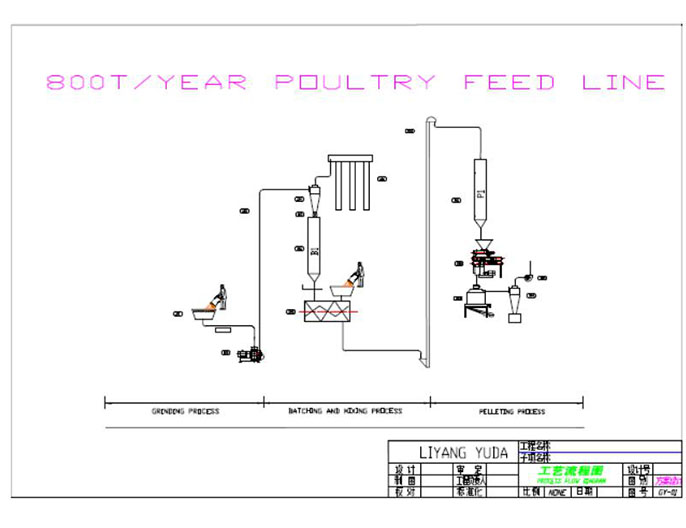

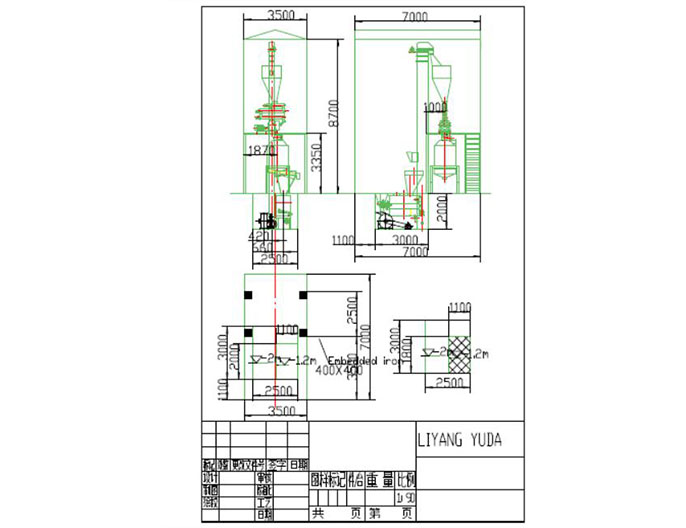

800 Poultry

Design Flow Chart

Project Machine List

Electric Control

| No. | Name | Model | Qty. | Power(KW) | ||

|---|---|---|---|---|---|---|

| Unit | Total | |||||

| Ⅰ.Grinding System | ||||||

| 101 | Feeding inlet, grizzly |

|

1 |

|

|

|

| 102 | Wide type hammer mill | SFSP50 | 1 | 15.00 | 15.00 | |

| 103 | Screw conveyor |

|

1 |

|

|

|

| 104 | Fan |

|

1 |

|

|

|

| 105 | Screw feeder | TGFZ5 | 1 | 0.55 | 0.55 | |

| 106 | Air lock |

|

1 |

|

|

|

| Ⅱ.Mixing System | ||||||

|---|---|---|---|---|---|---|

| 201 | Pre-mixing bin |

|

1 |

|

|

|

| 202 | Ribbon mixer | SLHY0.4 | 1 | 4.00 | 4.00 | |

|

|

Buffer bin |

|

1 |

|

|

|

| 203 | Bucket elevator | TDTG26/13 | 1 | 2.20 | 2.20 | |

| Ⅲ.Pelleting system | ||||||

|---|---|---|---|---|---|---|

| 301 | Pre-pelleting bin |

|

1 |

|

|

|

| 302 | Pellet mill | SZLH25 | 1 | 15.00 | 15.00 | |

| 303 | Manual plug board |

|

1 | 0.2*2 |

|

|

| 304 | Fan |

|

1 |

|

|

|

| 305 | Air lock feeder | 5-36-4A | 1 | 5.50 | 5.50 | |

-

Grinding System

Grinding System

-

Mixing System

Mixing System

-

Pelleting System

Pelleting System

-

Electronic Control System

Electronic Control System

-

-

| Ⅱ.Electronic Control System | ||||||

| 1 | Centralized control cabinet | |||||

| 2 | Cable, wire, trunking,cable tray, and other auxiliary material | |||||

| Ⅲ.Container type feed integral unit material | ||||||

| 1 | Air draft, dust removal, cooling ventilation network system. | |||||

| 2 |

Tube,equipment racks,platforms,noise-reduction tube,piping materials and non-standard parts. |

|||||

| 3 | Standard (gb), seals, solder pieces and other auxiliary materials; | |||||

| 4 | Paint(Means the painting make-up after reinstalling the equipment) | |||||

| 5 | Steam pipeline system | |||||

| Ⅳ.Design fee | For free | |||||

| Ⅴ.Installation fee(Means prepared assembly in China factory) | ||||||

| Ⅵ.Guiding installation fee in overseas | For free | |||||

| Ⅶ.Unexpected expenses | ||||||

| Ⅷ.Expedition fee | For free | |||||

| Ⅸ.Personal training fee | For free | |||||

TOP