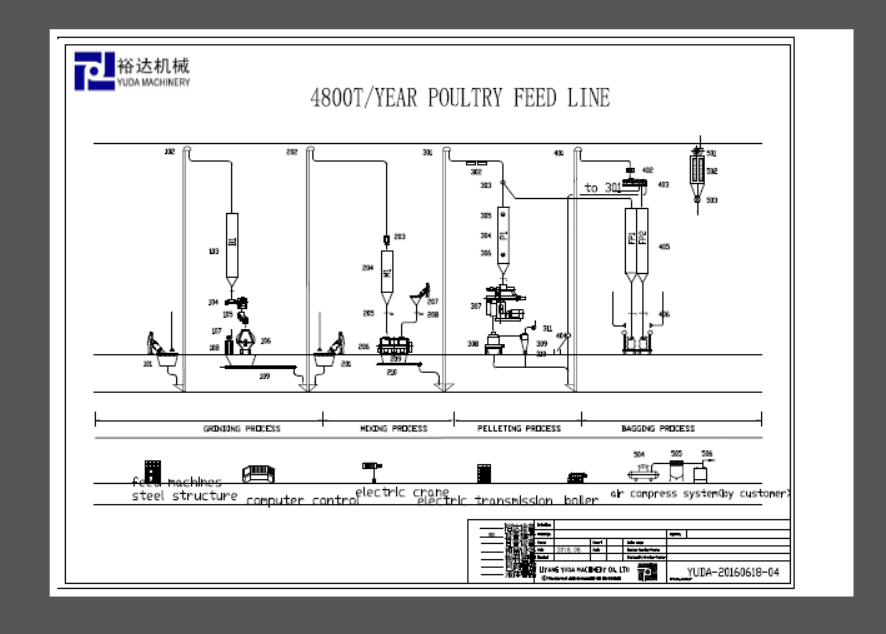

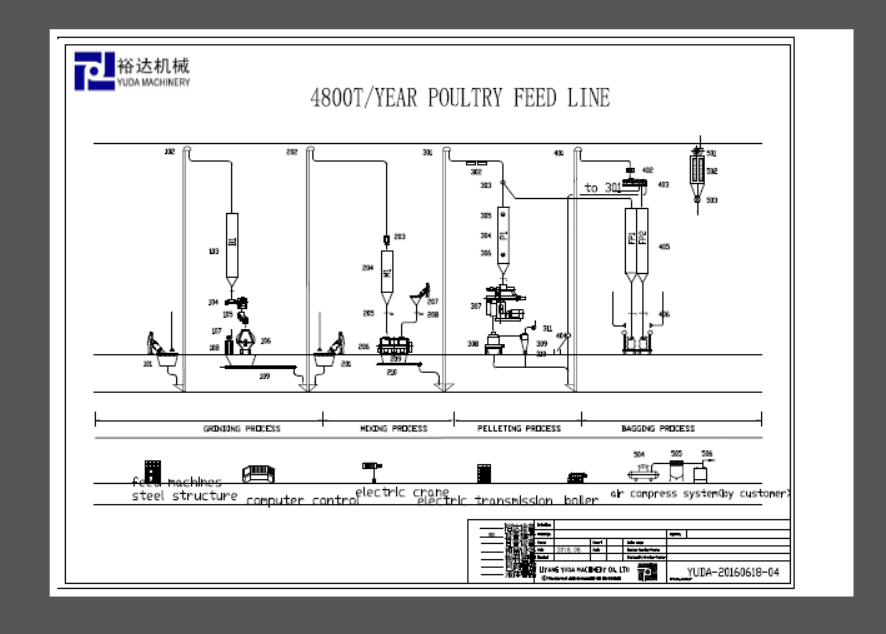

4800TY Poultry Feed Line

Design Flow Chart

Project Machine List

Project Machine List

Electric Control

| 4800 Container Type Feed Integral Unit Equipment List | ||||||

|---|---|---|---|---|---|---|

| No. | Name | Model | Qty. | Power(KW) | Remarks | |

| Unit | Total | |||||

| Ⅰ.Grinding System | ||||||

| 101 |

Feeding inlet, grizzly |

|

1 |

|

|

|

| 102 | Bucket elevator | TDTG36/18 | 1 | 1.50 | 1.50 | Anti-reversing device, around using the occlusion process, good rigidity |

| 103 | Pre-grinding bin | 1m³ | 1 |

|

|

|

| 104 | Feeding cleaning screener | TWCZ18 | 1 | 1.10 | 1.10 | Speed control |

| 105 | Magnet device | SCGY40 | 1 |

|

|

Made of stainless steel, high and strong magnetism |

| 106 | Wide type hammer mill | SFSP60*40 | 1 | 37.0 | 37.00 | Hammers type grinding, uniform sized, equipped with Φ2.5 sieve plate |

| 107 | Fan | 4-72No4A | 1 | 5.50 | 5.50 |

|

| 108 | Pulse dust jet filter | TBLMFa18(1500) | 1 |

|

|

Novel and efficient dust collector |

| 109 |

Air lock screw conveyor |

TLSS20 | 1 | 2.20 | 2.20 |

|

|

|

Subtotal |

|

|

|

47.30 |

|

| Ⅱ.Mixing System | ||||||

| 201 |

Feeding inlet, grizzly |

|

1 |

|

|

|

| 202 | Bucket elevator | TDTG36/23 | 1 | 2.20 | 2.20 | Anti-reversing device, around using the occlusion process, good rigidity |

| 203 | Magnet | TCXT20 | 1 |

|

|

|

| 204 | Pre-mixing bin | 1m³ | 1 |

|

|

|

| 205 | Pneumatic slide gate | TZMQ40×40 | 1 |

|

|

|

| 206 | Ribbon mixer | SLHY.1 | 1 | 11.00 | 11.00 | Tested by the national fishery machinery quality supervision and inspection center, gentle mixing process, short period and high mixing evenness. |

| 207 | Additive hopper |

|

1 |

|

|

|

| 208 | Pneumatic slide gate | TZMQ25×25 | 1 |

|

|

|

| 209 | Buffer bin |

|

1 |

|

|

|

| 210 | Screw conveyor | TLSS20 | 1 | 2.20 | 2.20 |

|

|

|

Subtotal |

|

|

|

15.40 |

|

| Ⅲ.Pelleting system | ||||||

| 301 | Bucket elevator | TDTG36/23 | 1 | 2.20 | 2.20 | Anti-reversing device, around using the occlusion process, good rigidity |

| 302 | Magnet device |

|

1 |

|

|

Made of stainless steel, high and strong magnetism |

| 303 | Pneumatic two way valve | TZMQ2×25/45 | 1 |

|

|

|

| 304 | Pre-pelleting bin | 2m³ | 1 |

|

|

|

| 305 | High level indicator |

|

1 |

|

|

|

| 306 | Low level indicator |

|

1 |

|

|

|

|

|

Manual plug board |

|

1 |

|

|

|

| 307 | Screw feeder |

matching with SZLH32 |

1 | 0.55 | 0.55 | Speed control feeding |

| Conditioner | matching with SZLH32 | 1 | 2.20 | 2.20 | Specification:Φ280×1600,multi-ponit steam inlet device | |

| Pellet mill | SZLH32 | 1 | 37.00 | 37.00 | Gear drive, small vibration, high driving efficiency; high capacity, can better produce high-quality feed. | |

| 308 | Air lock feeder |

|

1 | 0.55 | 0.55 |

|

|

|

Counterflow cooler | SKLN2.5 | 1 | 1.50 | 1.50 | Octangle structure, cooling well without dead angle |

| 309 | Discharging device |

|

1 |

|

|

|

| 310 | Air lock | GFZ.7 | 1 | 0.75 | 0.75 |

|

| 311 | Fan | 4-72N4.5A | 1 | 7.50 | 7.50 |

|

|

|

Subtotal |

|

|

|

52.25 |

|

| Ⅳ. Products Packing System | ||||||

| 401 | Bucket elevator | TDTG36/18 | 1 | 1.50 | 1.50 | Anti-reversing device, around using the occlusion process, good rigidity |

| 402 | Crumbler | SSLG15×100 | 1 | 5.50 | 5.50 | Fine serrated crumbling, uniform size |

| 403 | Rotary sifter | SFJH80×2d | 1 | 1.10 | 1.10 |

|

| 404 | Pneumatic two way valve | TZMQ2×25/45 | 1 |

|

|

|

| 405 | Product bin |

|

2 |

|

|

one for powder material bin, one for pellets material bin, manual packing |

| 406 | Manual butterfly valve |

|

2 |

|

|

|

|

|

Subtotal |

|

|

|

8.10 |

|

| Ⅴ.Auxiliary System | ||||||

| 501 | Fan | 4-72No4A | 1 | 5.50 | 5.50 |

|

| 502 | Pulse dust jet filter | TBLMFa.30(1500) | 1 |

|

|

Using imported solenoid valve, remove 4 cylinders. |

| 503 | Air lock | GFZ.5 | 1 | 0.55 | 0.55 |

|

| 504 | Air compressor |

|

1 | 7.50 | 7.50 |

|

| 505 | Air dryer |

|

1 |

|

|

|

| 507 | Air tank |

|

1 |

|

|

|

|

|

Container type large frame |

|

1 |

|

|

|

|

|

Subtotal |

|

|

|

13.55 |

|

|

|

Total Price |

|

|

|

136.60 |

|

|

Feed integral unit price list

|

|||||||

|

Project Name:4800 Container Type Feed Integral Unit(∮4mm pellets2-4T/H)

|

|||||||

|

Construction unit:

|

|||||||

|

No.

|

Name

|

Remarks

|

|||||

|

Ⅰ.Machinery (See Equipment List)

|

|||||||

|

Ⅱ.Electronic Control System

|

|||||||

|

1

|

Centralized control cabinet

|

||||||

|

2

|

Cable, wire, trunking,cable tray, and other auxiliary material

|

||||||

|

3

|

Site control cabinet

|

|

|||||

|

Ⅲ.Container type feed integral unit material

|

|||||||

|

1

|

Air draft, dust removal, cooling ventilation network system.

|

||||||

|

2

|

Tube,equipment racks,platforms,noise-reduction tube,piping

materials and non-standard parts. |

||||||

|

3

|

Standard (gb), seals, solder pieces and other auxiliary materials;

|

||||||

|

4

|

Pneumatic components and compressed air accessories, etc.

|

||||||

|

5

|

Paint(Means the painting make-up after reinstalling the equipment)

|

||||||

|

6

|

Steam pipeline system

|

Offer steam installation drawing and configuration list of pipeline.

|

|||||

|

Ⅳ.Design fee

|

For free

|

||||||

|

Ⅴ.Installation fee(Means prepared assembly in China factory)

|

|||||||

|

Ⅵ.Guiding installation fee in overseas

|

Installation fee in overseas $80/day/person

|

||||||

|

Ⅶ.Unexpected expenses

|

For free

|

||||||

|

Ⅷ.Expedition fee

|

|||||||

|

Ⅸ.Personal training fee

|

For free

|

||||||

|

Electric Control

|

|||||||

|

Notes:

|

1. The packing fee and transportation fee are not included;

|

3.The electrode when installation, oxygen, acetylene and other consumables for buyer's account.

|

|||||

|

2. The validity of this quote is in the 2 months.

|

4.Engineers abroad all costs for buyer's account.

|

||||||

TOP