Alloy 316/316L is molybdenum-bearing austenitic stainless steel. The higher nickel and molybdenum content in this grade allows it to demonstrate better overall corrosion resistant properties than 304, 316 stainless steel by adding Mo element, make its corrosion resistance, and improve the high temperature strength, high temperature can reach 1200-1200 degrees, can be used in critical conditions,especially with regard to pitting and crevice corrosion in chloride environments. In addition, Alloy 316/ 316L provides excellent elevated temperature tensile, creep and stress-rupture strengths, as well as outstanding formability and weldability. 316L is the lower carbon version of 316 and is immune from sensitization; therefore, it is very frequently used in heavy gauge welded components.

Chemical composition&Physical Properties

|

316 and 316L Stainless SteelChemicalComposition: |

||

|

Element |

Type 316 (%) |

Type 316L (%) |

|

Carbon |

0.08 max. |

0.03 max. |

|

Manganese |

2.00 max. |

2.00 max. |

|

Phosphorus |

0.045 max. |

0.045 max. |

|

Sulfur |

0.03 max. |

0.03 max. |

|

Silicon |

0.75 max. |

0.75 max. |

|

Chromium |

16.00-18.00 |

16.00-18.00 |

|

Nickel |

10.00-14.00 |

10.00-14.00 |

|

Molybdenum |

2.00-3.00 |

2.00-3.00 |

|

Nitrogen |

0.10 max. |

0.10 max. |

|

Iron |

Balance |

Balance |

|

316 &316L Mechanical properties |

|||

|

Tensile Strength σb (MPa)(min) |

520 |

480 |

|

|

Yield Strength σ0.2 (MPa) (min) |

205 |

177 |

|

|

Elongation δ5 %(min) |

40 |

40 |

|

|

Hardness (Brinell) max |

217 |

217 |

|

|

|

HB |

187 |

187 |

|

90 |

90 |

||

|

200 |

200 |

||

Corrosion resistance

Corrosion resistance is better than 304 stainless steel, in the process of pulp and paper production has good corrosion resistance performance. And 316 stainless steel is also resistant to aggressive industrial marine and atmospheric erosion.

Heat resistance

At 871 ° C intermittent use (1600 ° F) below and at 927C ° (1700 ° F) or more continuous use, 316 (06Cr17Ni12Mo2) has good resistance to oxidation. In the range of 427 ° C-857 ° C (800 ° F-1575 ° F), it is best not continuous use 316 stainless steel, but when outside the temperature range of continuous use 316 stainless steel, the stainless steel has good heat resistance. Resistant 316L stainless steel carbide precipitation performance better than the 316 stainless steel, available above temperature range.

Heat Treatment

Carried out in a temperature range of 1850-2050 ° F annealing, then rapidly annealed and then rapidly cooled. 316 stainless steel can not be hardened by heat treatment.

Welding

316stainless steel has goodweldability. All standardwelding methodscan be usedfor welding. Weldingaccording touse, respectively316Cb, 316Lstainless steelor309Cbweldingfillerrodsor rod. For optimumcorrosion resistance, stainlesssteel weldingsection316requirepost-weldannealing. If you useannealed316Lstainless steel, does not require welding

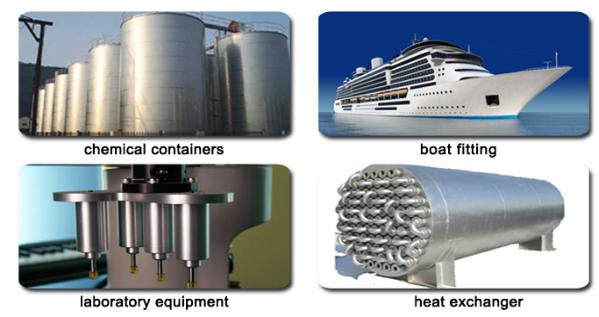

316/316L stainless steel Application

Typical applications include:

•Food preparation equipment particularly in chloride environments.

•Chemical processing, equipment

•Heat exchangers

•Marine applications

•Architectural applications

•Medical implants, including pins, screws and orthopaedic implants like total hip and knee replacements

•Fasteners