Machine technique data

Suitable Plate Material: thickness 0.8-1.5mm, Galvanized steel or blank steel

Working Speed: 12 meters / min

Forming Steps: 22 stations

Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

Driven system: Chain drive

Main Power with reducer: 11KW WH Chinese Famous

Cutting: Hydraulic Cutting Cr12mov

Material of Cutting Knife: Cr12Mov, Quench HRC58-62

Hydraulic Station Power: 4KW Wuxi Wanshen Famous Chinese Brand

The whole machine is controlled by industry computer-PLC.

PLC--Panasonic, Japan English and Chinese Language

Touch Screen--Panasonic Japan

Encoder--Omron, Japan

Electric parts--Schneider

Machine component

Machine name

Quantity

3T hydraulic un-coiler

1 set

Leveling device 300mm

1 set

Servo feeding device 300mm

1 set

Press machine JH21-63

1 set

Main roll forming machine

1 set

Cutting holder

1 set

Hydraulic station

1 set

Control system ( including control box)

1 set

Hydraulic Cutting die

1 set

Punching die set

1 set

Out tables

1 set

Cassettes

3 sets

Spare parts

1 package

Machine profile drawing

1 set

Sussman hereby solemnly promises: We implement the “three guarantees” service policy for any equipments sold by Sussman, provide free of charge installation guidelines, commissioning and maintenance of the equipments, training of the Buyer’s relevant Operators; and provide technical requirements for the installation and operation of the equipments, technical layout diagrams and other related information, provide a lifetime supply of maintenance and spare parts

The detailed measures are as follows:

1.Guidelines for installation and commissioning of equipments:

Based on the actual situation, to assist and guide the Buyer and Buyer’s technical personnel in the overall installation location, the installation of equipments, and provide Buyer with answers to their questions and related issues;

2.Provide training for operation and maintenance personnel:

Based on the Buyer’s request, Sussman will provide free of charge training of the operation and maintenance personnel;

a) The User (Buyer) can send their operation and maintenance personnel to our factory for learning and training;

b) When Sussman is doing the installation and test running of the equipments for the Buyer, the Buyer can send their personnel to participate.

3.If failure occurs in any of the machines during the “three guarantees” period(one year), three guarantees including the electricity parts, the rolls, the shafts and punching& cutting moulds, then, upon the Buyer’s request, Sussman will eliminate the failure;

4. Sussman will inform all its Buyers about any upgrades and significant product improvements. Sussman will provide equipment modifications based on their costs. Sussman will provide Buyers with high-quality after-sales services in a careful and responsible attitude, provide very strong guarantee for the Buyer’s normal production.

We provide quick and satisfactory customer service, and promise to respond within 24 hours after receiving your complaints by phone or email

-

Roll Forming Machine

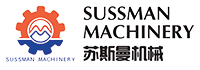

- Drywall Stud track Roll Forming Machine

- Cable Tray Roll Forming Machine

- CZ Purlin Roll Forming Machine

-

Roller Shutter Door Machine

- Awning Tube Roll Forming Machine

- Windows Shutters Insulated Slat Machine

- Shutter Bottom Roll Forming Machine

- Curtain Rail Roll Forming Machine

- Metal Rolling Shutter Door Machine

- Double layer Insulated Shutters Door Forming Machine

- Embossing Machine

- J Track Roll Forming Machine

- L Profile Forming Machine

- Octagonal Pipe Machine

- Sectional Doors Panel Production Line

- Shutters Box Series Forming Machines

- Track Rail Automatic Bending Machine

- Track Rail Forming Machine

- U Channel Roll Forming Machines

- V Strut Forming Machine

- Windows & Doors Foam Insulated Shutters Slat Machine

- Guide Rail Roll Forming Machine

- Strut Roll Forming Machine

- Roof Panel Roll Forming Machine

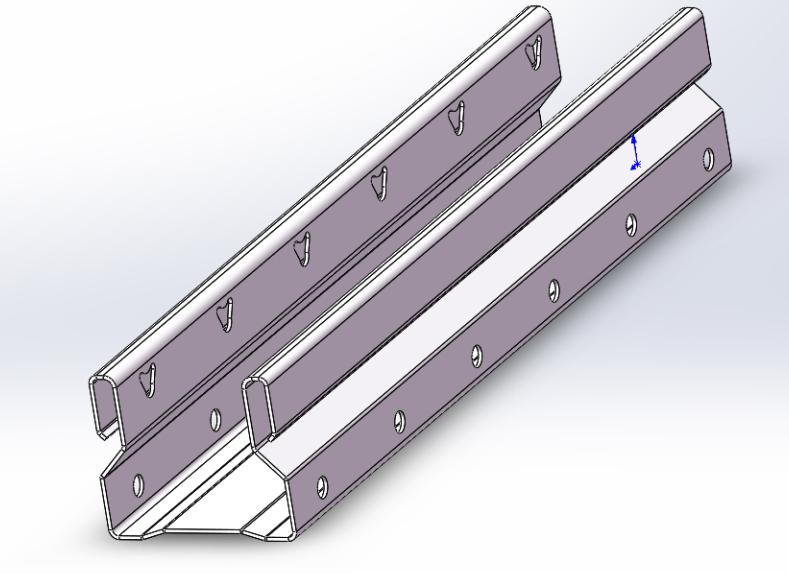

- Racking Shelf Roll Forming Machine

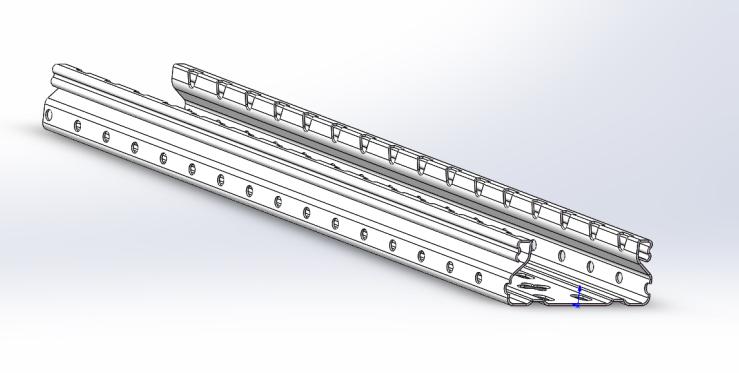

- Deck Floor Roll Forming Machine

- Fire Damper Roll Forming

- Guard Railway Roll Forming Machine

- Gutter Roll Forming Machine

- Down Spout Roll Forming Machine

- Door Frame Roll Forming Machine

- Vineyard Post Roll Forming Machine

- Fence Post Roll Forming Machine

- Round Pipe Roll Forming Machine

- VIGACERO Ceiling Rail Roll Forming Machine

- Weld Tube Mill

- Weld Round Pipe Machine

- Decorative PU sandwich wall panel

- Slitting Machine

- Auxiliary Machine

- PU Sandwich Panel Line