00:18

00:18

Model XTHZ-10 Driving Mode Servo motor labeling methods The bottle is stand into, stand labeling, stand out Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The size of bottle Outer diameter 20-100mm, height 25-200mm The size of label Height 20-180 mm length 25-200 mm Printer to use air 5kg/cm ² Voltage AC220V 50/60HZ Single side (Can customized as buyer need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:03

01:03

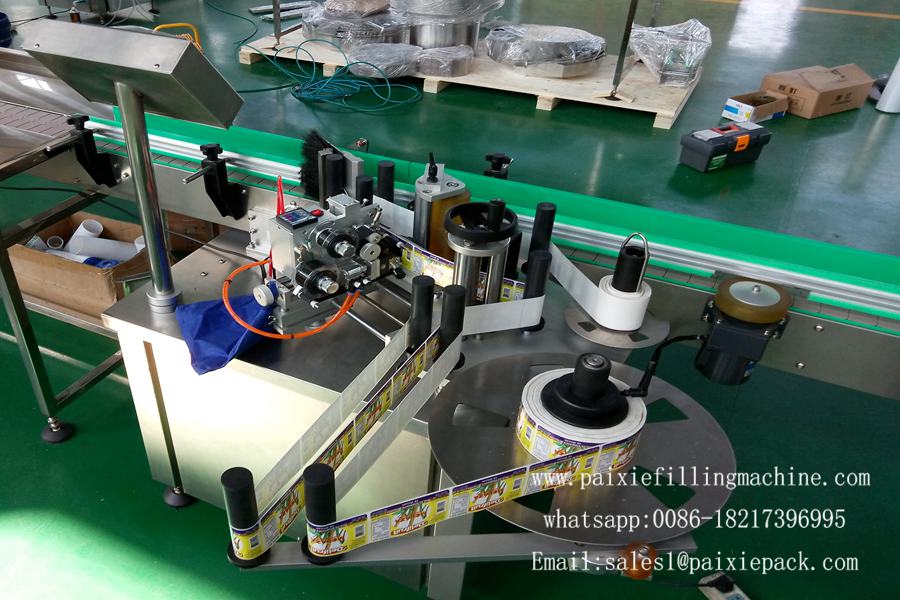

Overview : The Paixie Pack labeling machine have different types full automatic labeling machine suitable for round /flat /square/ irregular shape bottles . We have three types of the labeling machine adhesive labeling machine, glue wet labeling machine ,sleeve shrink labeling machine . Our Labeling machine is also suitable for all kinds of one side two sides neck labeling and so on. 1.Configuration oftaliban type coping mechanism, to ensure product delivery smoothly, and effectively eliminate bottle of high error in itself; 2.Configure automatic bottle body, guide the bottle before automatically separate spacing, ensure follow-up guide bottle, conveying and stick mark stability; 3.Mixer equipment mainly senior materials using 304 stainless steel and aluminum alloy, in line with the GMP standard production, overall structure and firm, the beauty is generous. 4.In pieces the electrical equipment USES is Panasonic servo motor, Mitsubishi electric eye, ensure the accuracy and speed stick mark requirements. After sale service : (1) Long life service (2) One year warranty (3) Offering free parts for one year (4) Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 01:26

01:26

Model PM-DPM Driving Mode Servo motor Yield(pcs/min) 30-180 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 1000W Weight(kg) 500 Machine size 2900(L) 1200 (W) 1600 (H) mm (machine size can made as client need )

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:19

01:19

Model ELM-S Driving Mode Servo motor Operating direction Left or Right Labeling position Top and two more sides on egg carton Conveyor speed ≤40 (m/min) Label Specifications Adhesive sticker , opaque label The application of label object Customized as the egg carton The application of label Height 20-180mm Length 25-300mm The inner diameter of label roll 76mm The outer diameter of label roll 350mm(max) Voltage (In China) AC220V 50/60HZ Single phase

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:07

01:07

Model PWM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-220 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-100 mm length 15-80 mm The suitable size of labeling objects Customized depends on client product Printer use air 5kg/cm ² Power(w) 600W Weight(kg) 200 Machine size 1800(L) 800 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:53

00:53

Model BFM-D Driving Mode Servo motor Yield(pcs/min) 20-120 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-80 mm length 15-100 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:30

01:30

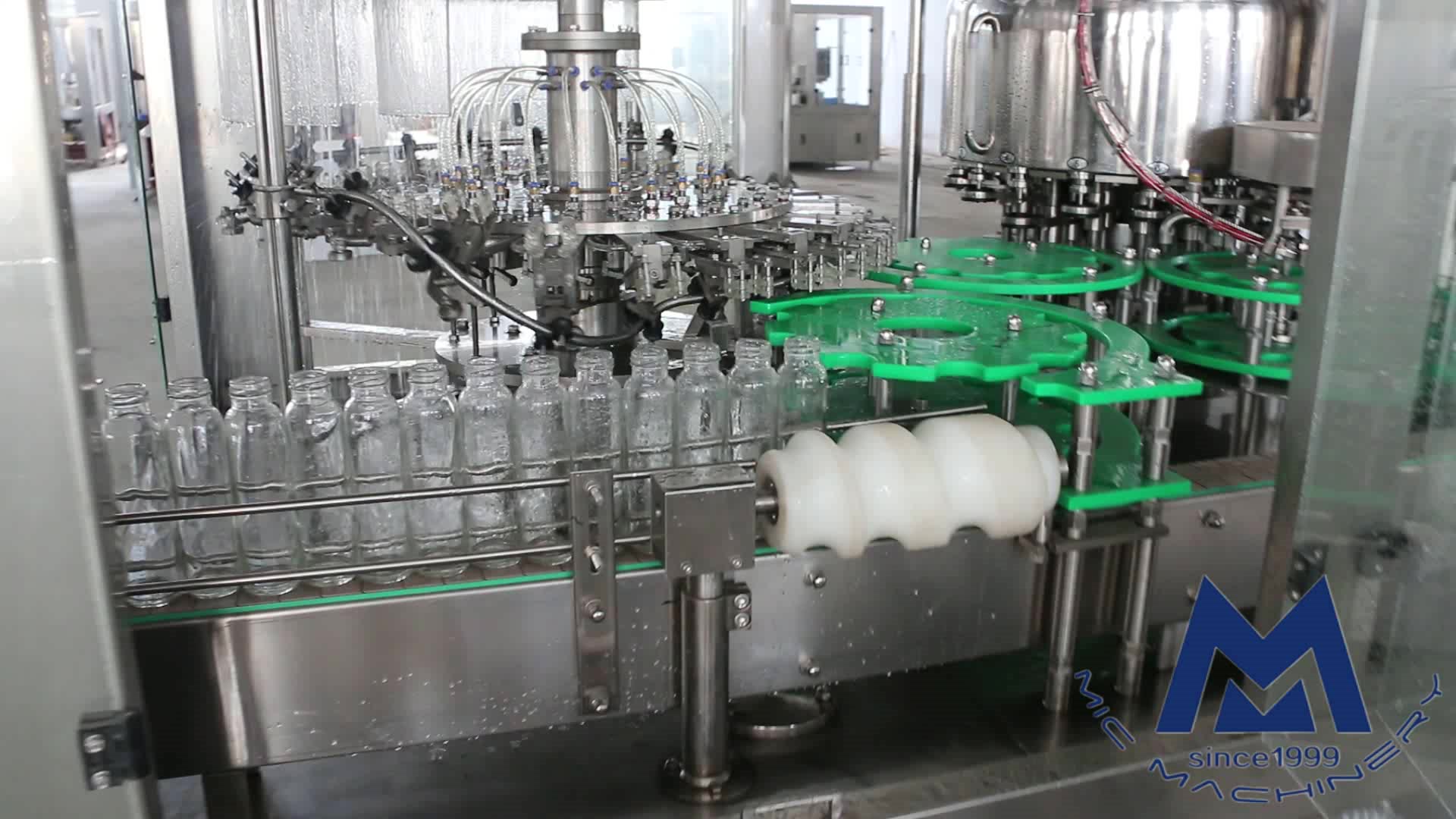

MIC 18-18-6 It is applicable for glass bottle filling capping machine for whisky, alcohol drinks and spirit. (if need hot filling temperature at 85-90 degree) Adopt products: whisky ,alcohol drinks, spirit, chivas, liquor, vodka, vinegar, soy sauce etc liquid products. Machine working principle: 1. Negative pressure filling(slightly), controled by pressure, accuracy is +/-1%,liquid level difference is not more than 4-5mm(cause bottle has difference when it produced). easy adjustmeant on liquid level. 2. Glass bottle capping machine is qualified for Chinese capping standard, and no air leakage at all, machine capping rate is 99.5%. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum cap and crown cap are ok problem working on our capping machine(different capping head), We use our own technical drawing and own processing machine, to make sure our capping head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> CIP cleaning system 8> Pasteurization, inventor and sterilizing tunnel. 9> Glass bottle air washing machine Related machines are: Glass bottle filling machine, glass bottle capper, glass bottling companies, bottle filling machine, bottle equiment, bottle filling, bottle filling capping machine, bottle filler, bottle capper, bottle capping machine, crown bottle capper, bottle capping machine price, Whisky filling capping machine, vodka filling capping machine, liquor filling machine, spirit filling machine. Lately news for shipment: →We sold one to Belize on May 10,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:20

01:20

MIC 24-24-6 It is applicable for glass bottle filling capping machine for whisky, alcohol drinks and spirit. (if need hot filling temperature at 85-90 degree) Adopt products: whisky ,alcohol drinks, spirit, chivas, liquor, vodka, vinegar, soy sauce etc liquid products. Machine working principle: 1. Negative pressure filling(slightly), controled by pressure, accuracy is +/-1%,liquid level difference is not more than 4-5mm(cause bottle has difference when it produced). easy adjustmeant on liquid level. 2. Glass bottle capping machine is qualified for Chinese capping standard, and no air leakage at all, machine capping rate is 99.5%. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum cap and crown cap are ok problem working on our capping machine(different capping head), We use our own technical drawing and own processing machine, to make sure our capping head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> CIP cleaning system 8> Pasteurization, inventor and sterilizing tunnel. 9> Glass bottle air washing machine Related machines are: Glass bottle filling machine, glass bottle capper, glass bottling companies, bottle filling machine, bottle equiment, bottle filling, bottle filling capping machine, bottle filler, bottle capper, bottle capping machine, crown bottle capper, bottle capping machine price, Whisky filling capping machine, vodka filling capping machine, liquor filling machine, spirit filling machine. Lately news for shipment:

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 00:42

00:42

Model DPM-ALS104 Driving Mode German Avery Yield(pcs/min) 30-200 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 1000W Weight(kg) 500 Machine size 2900(L) 1200 (W) 1600 (H) mm (machine size can made as client need )

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:58

01:58

MIC 12-1 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> CIP cleaning system 7> CIP cleaning liquid recycle system 8> Ink date printer (LINX BRAND) Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. Recent export news: (click for check news) →We sold one to the United States of America on May 18,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:12

01:12

MIC 18-18-1 It is applicable for glass bottle filling capping machine for whisky, alcohol drinks and spirit. (if need hot filling temperature at 85-90 degree) Adopt products: whisky ,alcohol drinks, spirit, chivas, liquor, vodka, vinegar, soy sauce etc liquid products. Machine working principle: 1. Negative pressure filling(slightly), controled by pressure, accuracy is +/-1%,liquid level difference is not more than 4-5mm(cause bottle has difference when it produced). easy adjustmeant on liquid level. 2. Glass bottle capping machine is qualified for Chinese capping standard, and no air leakage at all, machine capping rate is 99.5%. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum cap and crown cap are ok problem working on our capping machine(different capping head), We use our own technical drawing and own processing machine, to make sure our capping head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> CIP cleaning system 8> Pasteurization, inventor and sterilizing tunnel. 9> Glass bottle air washing machine Related machines are: Glass bottle filling machine, glass bottle capper, glass bottling companies, bottle filling machine, bottle equiment, bottle filling, bottle filling capping machine, bottle filler, bottle capper, bottle capping machine, crown bottle capper, bottle capping machine price, Whisky filling capping machine, vodka filling capping machine, liquor filling machine, spirit filling machine. Lately news for shipment: We sold one to

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 00:53

00:53

Model BFM-D Driving Mode Servo motor Yield(pcs/min) 20-120 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-80 mm length 15-100 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery