00:02

00:02

Machine list Machine list 3 ton passive de-coiler 1 set Main roll forming machine 1 set Punching device 1 set Cutting device 2 sets PLC Control box 1 unit Hydraulic station 1 unit Out table 2 units Safety cover 1 unit Parameter Items Specifications Remarks Material of coil Thickness 0.27-1mm galvanized steel De-coiler Weight 3 ton manual Forming system Rolling Speed 0-10m/min Embossing At sides Roller Stations About 13 stations forming Roller Material Cr40 Steel with quenching Shaft Material 45# Steel Diameter 60mm shaft Motor Power 7.5 kw Hydraulic cutting Power 4 kw Cutting system Material of cutting CR12 with quench treatment Hardness HRC58-62 Tolerance +-1.5mm Cutting blade 1 set of cutting blade Electrical control system Electric Source 380V, 60HZ,3 phase Control System PLC Weight About 3 tons Way Of Drive 1 inch single chain Size of machine Length 5500mm* Width 600mm* Height 800m Machine picture Product

We have high technological background, advanced production equipment, strict inspection,matured after-sales work and thoughtful service.

Contact Supplier 00:00

00:00

Special rollers design, more precise and solid Shaft diameter: 75 or80mm, according to profile Wall plate 18mm thick Mitsubishi PLC and converter Tool box and technical support

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 03:34

03:34

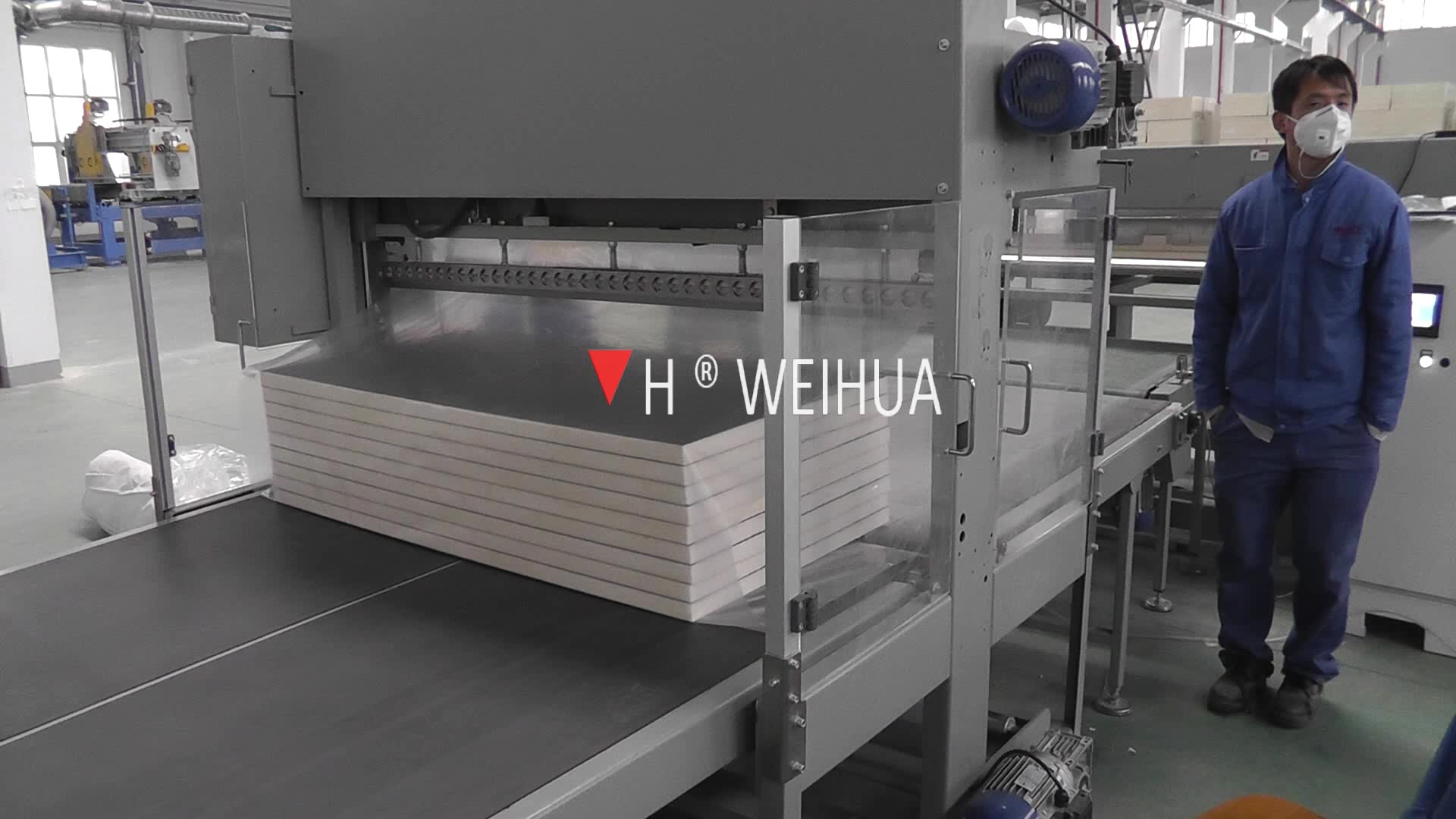

3+3 pressing machine greatly reduces the workers labor intensity, save labor time, and increase production efficiency. This machine requires no foundation work, which results in less site area and reduced capital investment. This device uses a contact heater, can set the pre-heating time and also can automatically disconnect the power supply during the worker's operation, make sure safe and reliability. This equipment adopts left and right alternate pressing. The left mold is in the process of pressing. The worker operates the right mold. When the right mold is used for stamping, the left mold is assembled. The time of one cycle greatly improves the working efficiency. The hydraulic system features self-starting and self-stop technology. The machine is equipped with a 7-inch touch screen, use human-machine interface and easy to operate.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:00

00:00

Special rollers design, more precise and solid Shaft diameter: 55mm or more, according to profile Wall plate 18mm thick Mitsubishi PLC and converter Tool box and technical support

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 01:23

01:23

No. Name Unit Parameter 1. Control model PLC PLC frequency control 2. Applied to Mild steel (Soft) and High Tensile ( GI) 3. Thickness mm 0.5-3.0 4. Width mm 1270 5. ID mm Φ508 6. OD mm ≤1600 7. Coil weight Ton ≤5 8. Slitting blade shaft mm Φ180 9. Blade specification mm Φ320×Φ180×15 10. Material of blade 6CrW2Si 11. Power of slitter KW 30 12. Quantity of strips (Max) pcs 4 13. Width tolerance ≤±0.05 mm 14. Leveling roller diameter mm 65 15. Number of leveling rollers 70 16. Material of leveling roller GCr15 17. Material of cutter blade 6CrW2Si 18. Speed m/min ≤30 19 Length tolerance L=2m ≤±0.5 20. Diagonal tolerance L=2m ≤±1 mm 21. Power 380V/3PH/50HZ 22. Machine color White

Zhengchuang Machinery is a manufacturer of high-end roll forming machine in Asia. Wuxi Zhengchuang Cold Bending Technology Co., Ltd was establish in 1995, with more than 20 years history in cold bending industrial area. Our company is located in Wuxi city, Jiangsu Province, floor area is about 15,000M2. We are professional manufacturing all kinds of cold bending machines, with the 23 years development, we use modern management, professional scientific research, advanced manufacturing technique and impeccable after-sales system, we obtain national high-tech enterprise title, until now our company has more than 80 employees. What we offer? Zhengchuang is mainly produce color steel tile roll forming machine, glazed tile roll forming machine, C/Z purline roll forming machine, quick change roll forming machine, deck floor roll forming machine, guardrail roll forming machine, downpipe roll forming machine, automotive frame roll forming machine, steel silo roll forming machine etc. We can make more than 20 series 100 kinds machines. The end product is widely used in grain storage, storeroom, workshop, supermarket shelves, photovotaic industry, villa, integration wall space, residence, and all kinds of heated housing construction project. Zhengchuang machine can meet growing demand of construction enterprise, auto industry and steel production enterprise.

Contact Supplier 01:38

01:38

I1. Specifications: applied to : Cold rolled steel, galvanized steel, hot rolled steel Tensile strength:δb≤450Mpa,δS≤280Mpa thickness:0.3-3.0mm width:500-2000mm(Max) coil ID: φ508mm coil OD:φ1800mm(Max) weight :15T(Max) diameter of leveling rollers: φ84mm distance of leveling rollers:90mm, material of leveling roller:GCr15,hardness:HRC55-60 total weight of machines:around 32T a. diagonal tolerance:≤±1mm/2000mm length tolerance:≤±0.5mm/2000mm a. power :380V/50Hz/3Ph c. d. area of the whole production line(about) 24m(L)X8m(W) f. g. color of the machines: grass green Ⅱ. Composed devices ■Hydraulic de-coiler ■Looper ■Servo precision straightening machine ■Transportation table ■Pneumatic stacker device ■Pneumatic system ■Electrical system

Zhengchuang Machinery is a manufacturer of high-end roll forming machine in Asia. Wuxi Zhengchuang Cold Bending Technology Co., Ltd was establish in 1995, with more than 20 years history in cold bending industrial area. Our company is located in Wuxi city, Jiangsu Province, floor area is about 15,000M2. We are professional manufacturing all kinds of cold bending machines, with the 23 years development, we use modern management, professional scientific research, advanced manufacturing technique and impeccable after-sales system, we obtain national high-tech enterprise title, until now our company has more than 80 employees. What we offer? Zhengchuang is mainly produce color steel tile roll forming machine, glazed tile roll forming machine, C/Z purline roll forming machine, quick change roll forming machine, deck floor roll forming machine, guardrail roll forming machine, downpipe roll forming machine, automotive frame roll forming machine, steel silo roll forming machine etc. We can make more than 20 series 100 kinds machines. The end product is widely used in grain storage, storeroom, workshop, supermarket shelves, photovotaic industry, villa, integration wall space, residence, and all kinds of heated housing construction project. Zhengchuang machine can meet growing demand of construction enterprise, auto industry and steel production enterprise.

Contact Supplier 01:31

01:31

1. Rolling material: thickness 1.5-3.0mm, yield strength ≤G250MPa; 2. Forming step: 18 steps; 3. Machine structure: with Terri structure; 4. Roller table design: with coaxial design, to reduce the unequal height of the two edges; 5. 8mm Roller material: GCr15 (bearing steel) with quenching treatment and surface chroming, the roller quenching hardness: HRC56°-62°; roller quenching depth: 8mm; 6. Main shaft material: qualified 45Cr steel with heat treatment and surface hard chroming; 7. Driving method: by hydraulic motor. Hydraulic station power: 22kw; 8. Forming speed: 17-21m/min; 9. Punching/cutting method: forming, punching , cutting; single hole + double holes 14X24; 10. Material for punching Dies & cutting blade: Cr12Mov; 11. Computer controlling system: industrial computer Siemens PLC system; Omron encoder; Schneider Electric, etc. 12. Main machine measurements: 10m×1.1m×1.5m (length x width x height);

Zhengchuang Machinery is a manufacturer of high-end roll forming machine in Asia. Wuxi Zhengchuang Cold Bending Technology Co., Ltd was establish in 1995, with more than 20 years history in cold bending industrial area. Our company is located in Wuxi city, Jiangsu Province, floor area is about 15,000M2. We are professional manufacturing all kinds of cold bending machines, with the 23 years development, we use modern management, professional scientific research, advanced manufacturing technique and impeccable after-sales system, we obtain national high-tech enterprise title, until now our company has more than 80 employees. What we offer? Zhengchuang is mainly produce color steel tile roll forming machine, glazed tile roll forming machine, C/Z purline roll forming machine, quick change roll forming machine, deck floor roll forming machine, guardrail roll forming machine, downpipe roll forming machine, automotive frame roll forming machine, steel silo roll forming machine etc. We can make more than 20 series 100 kinds machines. The end product is widely used in grain storage, storeroom, workshop, supermarket shelves, photovotaic industry, villa, integration wall space, residence, and all kinds of heated housing construction project. Zhengchuang machine can meet growing demand of construction enterprise, auto industry and steel production enterprise.

Contact Supplier 00:00

00:00

Special rollers design, more precise and solid Shaft diameter: 55mm or more, according to profile Wall plate 18mm thick Mitsubishi PLC and converter Tool box and technical support

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 00:12

00:12

Dimension:5800MM*2500MM*2600MM Core: Modified EPS, mineral wool, rock wool, glass wool Core density: Modified EPS: 25g Rock wool /mineral wool: 70g Glass wool: 50g Panel thickness: 40mm ( or customized) Steel thickness: 0.3mm (or according to the customer requirements) Dimension after folded: 400mm Application: Residence, office, factory, toilet, etc. Advantages: Fire insulation, saving cost, saving time, wide application

Zhengchuang Machinery is a manufacturer of high-end roll forming machine in Asia. Wuxi Zhengchuang Cold Bending Technology Co., Ltd was establish in 1995, with more than 20 years history in cold bending industrial area. Our company is located in Wuxi city, Jiangsu Province, floor area is about 15,000M2. We are professional manufacturing all kinds of cold bending machines, with the 23 years development, we use modern management, professional scientific research, advanced manufacturing technique and impeccable after-sales system, we obtain national high-tech enterprise title, until now our company has more than 80 employees. What we offer? Zhengchuang is mainly produce color steel tile roll forming machine, glazed tile roll forming machine, C/Z purline roll forming machine, quick change roll forming machine, deck floor roll forming machine, guardrail roll forming machine, downpipe roll forming machine, automotive frame roll forming machine, steel silo roll forming machine etc. We can make more than 20 series 100 kinds machines. The end product is widely used in grain storage, storeroom, workshop, supermarket shelves, photovotaic industry, villa, integration wall space, residence, and all kinds of heated housing construction project. Zhengchuang machine can meet growing demand of construction enterprise, auto industry and steel production enterprise.

Contact Supplier 00:34

00:34

After the stacked panels go into the wrapping machine through the transmission rollers, cover the thin film on the composite boards. According to the principle of expansion and contraction, the wrapping machine heats the thin film to frap the panels entirely. This process is called thermoplastic film wrapping.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:14

00:14

1)Auto stacker system is composed of conveyor roller, pushing device, lifting mechanism and stacking transverse etc. 2)Handling device of auto stacker adjusts speed by transducer. It brakes promptly positon precisely when the panels arrive at the preset location so that the work pieces can be stacked neatly. 3)There is no sliding friction in the whole process of stacking to make sure that no damage on the surface of panels. Auto stacker includes high-speed movable conveyor and transmission parking device. After stacking, the panels enter into the wrapping machine thought transmission rollers.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:25

00:25

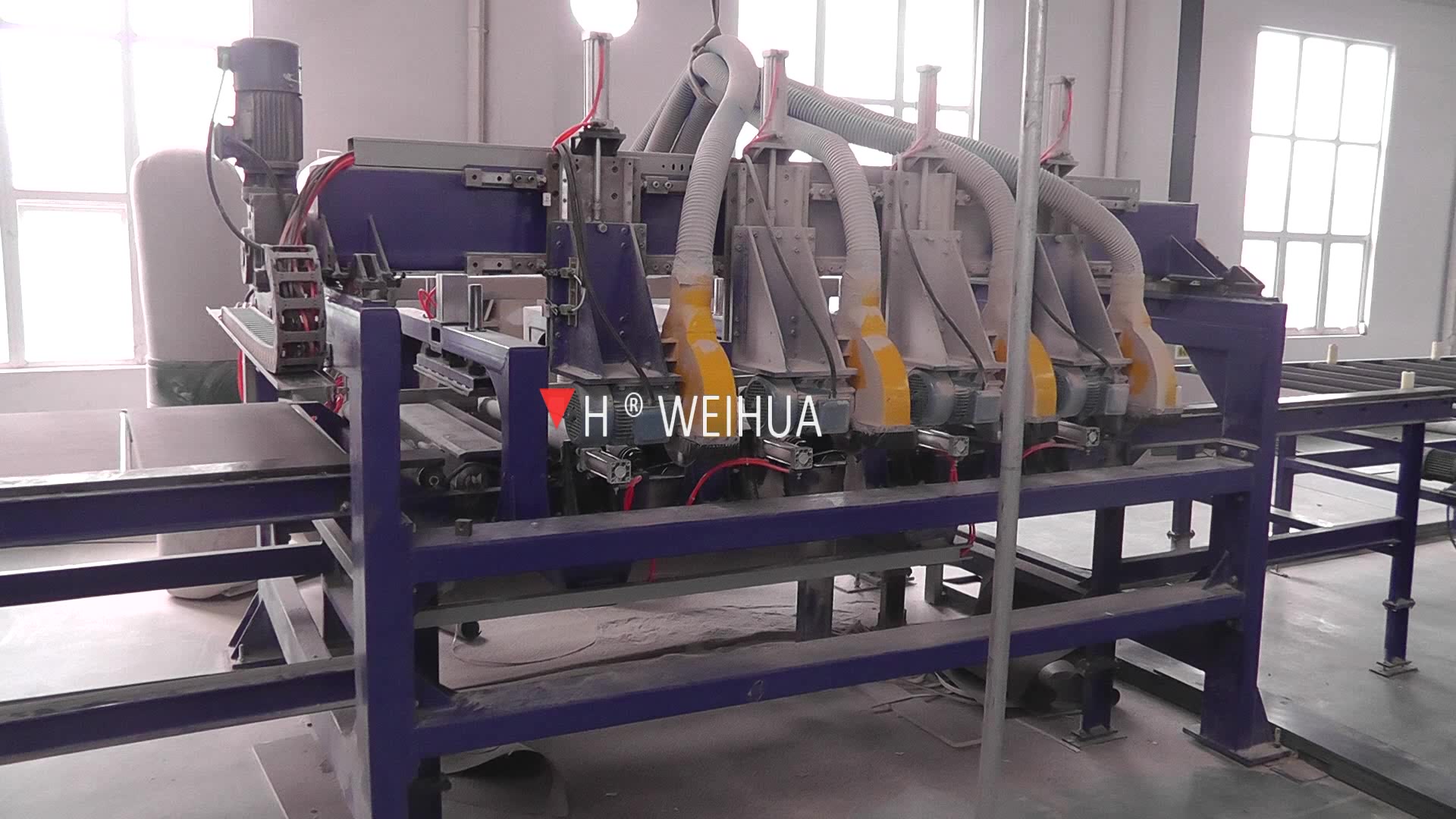

Soft and hard layer horizontal cutting device is used for cutting the large size panel from the production line into finished product,Usually the panel from production line is 1200*2400mm,and after this equipment then one-time to be cutting into 1200*600mm finished product.This equipment has high efficient,simple construction and easy operation. Soft and hard layer horizontal straddle cutting device firstly transfer the panel into cutting assembly,then the tip cylinder block lift to ward off the panel,make the panel vertical orientation;Side cylinder block stretch out to push the panel to fixed side baffles and clamp,make the panel horizontal orientation’Four power head fall down at the same time,compress roller compress panel,power head drive the disk saw to cut the panel from the origin point,after cutting,power head lift to original position and wait for next work cycle.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery