Shanghai SIO Electromechanical Technology Co., Ltd. founded in 2004, is an innovation-oriented hi-tech enterprise and an international trading company in CNC machine fields. In Shanghai SIO company, we have a team of experts with both technology and management experiences accumulated through long-term cooperation with domestic and foreign clients. We strive to provide affordable and durable CNC machine tools and automation solutions for both domestic and international markets. As the result of our diligent work, we are now a researching and manufacturing base of industrial automation technology and equipment such as CNC Metal Spinning Machine, Facing and Centering Machine, Cam Milling Machine, Spline Milling and Grinding Machine etc. SIO machines have been equipped for aerospace industry, military industry, state-owned enterprises, listed companies and other industry enterprises. SIO holds a good reputation in both machine tools’ industry and manufacturing industry. We are also the agent for trading Machining Centers, Drilling and Tapping Center, Turning and Milling composite Machine tool, Planer type Milling Machine, EDM Machine, Key Cutting Machine, Vacuum Pump, Oxygen Pump, Ventilation and hardware tools etc. The continents of exportation for our products include Europe, America, Asia and Africa. We appreciate your sincere cooperation with SIO, for the development and manufacture of the best machine tools and automatic equipment. SIO will be your trusted brand that provides cutting edge technology, exceptional quality, excellent service for a reasonable price. Connotation of SIO: Step ahead in technology Invent efficient machines Offer excellent service… Mission: To enhance modern manufacturing with technology Vision: To be leading brand in intelligent manufacturing field Philosophy: To create maximum value for our honored clients

- Contacter: 王先生

- Tel: +86-17740864896

- Fax: +86-21-67965066

- Email: sio@vip.163.com

-

Company Address:

Office 1001, No. 173, Guangji Rd. Hongkou Dist. Shanghai, China

Surgical Mask Machine

Supply automatic or semi-automatic surgical mask machines and Parts.

Surgical Mask Machine

Supply automatic or semi-automatic surgical mask machines and Parts.

N95 Mask Making Machine

Supply automatic or semi-automatic N95 mask making machines and parts.

N95 Mask Making Machine

Supply automatic or semi-automatic N95 mask making machines and parts.

CNC Cam Milling Machine (Linear Guide Rail) SIO-CM300L

Purpose of Machine Tool:

SIO-CM300L CNC Cam Milling Machine (Linear Guide Rail) is a modern machine with high efficiency, high precision and high rigidity. It was developed by SIO company and has patents issued by the SIPO. It is mainly used for half finishing or finishing camshafts like S type brake camshafts. Machining cams become very fast and easy. The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for automobile, mechanic and other manufacturing industries.

General Description & Main Features:

Machine Bed

The machine bed made by high-grade cast is implemented in stable horizontal framework in order to provide high accuracy and consistent repeatability. The outstanding sturdy machine body is heat treated to relieve stresses.

In line with the torsion resisting and sturdy construction, the linear guide rail slider is equipped with ball screws which have high stiffness, accuracy and excellent dynamic performance. Each of these units is driven via high precision servo motor, complete with position feedback system.

The work pieces are processing on the precision index head. Patents technology ensures the work piece has high degree of symmetry and rapid positioning.

Milling Heads

The milling heads mounted on the slides located. Adopt independent unit to ensure good movement precision, stiffness and stability. The drive of the milling heads is conducted via an AC vector motor and via a belt drive to the headstock input pulley.

Hydraulic Unit

The hydraulic unit is a unit connected to the chuck via generously dimensioned hydraulic piping. The hydraulic oil is cooled using an oil heat exchanger.

Dual hydraulic chuck makes automatic clamping. The chuck has internal blowing clearance system. Horizontal positioning with hydraulic lifting. Rapid back after installation.

Electrical control

Relevant parts of the electrical control system of the machine are contained in a switch gear cabinet.

Operating Panel

The machine is equipped with a computer numerical control system Siemens 808D with USB port.

Mobile manual pulse generator is equipped to easy operate.

Accessory

Integrated automatic lubrication system makes the maintenance more reliable.

Configuration cooling pump and enclosed shield.

Equipped automatic chip removal device.

Optional Accessories (Extra Price):

NC system such as FANUC,Siemens,GSK or KND is available for your selection.

CNC Cam Milling Machine (Linear Guide Rail) SIO-CM300L

Purpose of Machine Tool:

SIO-CM300L CNC Cam Milling Machine (Linear Guide Rail) is a modern machine with high efficiency, high precision and high rigidity. It was developed by SIO company and has patents issued by the SIPO. It is mainly used for half finishing or finishing camshafts like S type brake camshafts. Machining cams become very fast and easy. The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for automobile, mechanic and other manufacturing industries.

General Description & Main Features:

Machine Bed

The machine bed made by high-grade cast is implemented in stable horizontal framework in order to provide high accuracy and consistent repeatability. The outstanding sturdy machine body is heat treated to relieve stresses.

In line with the torsion resisting and sturdy construction, the linear guide rail slider is equipped with ball screws which have high stiffness, accuracy and excellent dynamic performance. Each of these units is driven via high precision servo motor, complete with position feedback system.

The work pieces are processing on the precision index head. Patents technology ensures the work piece has high degree of symmetry and rapid positioning.

Milling Heads

The milling heads mounted on the slides located. Adopt independent unit to ensure good movement precision, stiffness and stability. The drive of the milling heads is conducted via an AC vector motor and via a belt drive to the headstock input pulley.

Hydraulic Unit

The hydraulic unit is a unit connected to the chuck via generously dimensioned hydraulic piping. The hydraulic oil is cooled using an oil heat exchanger.

Dual hydraulic chuck makes automatic clamping. The chuck has internal blowing clearance system. Horizontal positioning with hydraulic lifting. Rapid back after installation.

Electrical control

Relevant parts of the electrical control system of the machine are contained in a switch gear cabinet.

Operating Panel

The machine is equipped with a computer numerical control system Siemens 808D with USB port.

Mobile manual pulse generator is equipped to easy operate.

Accessory

Integrated automatic lubrication system makes the maintenance more reliable.

Configuration cooling pump and enclosed shield.

Equipped automatic chip removal device.

Optional Accessories (Extra Price):

NC system such as FANUC,Siemens,GSK or KND is available for your selection.

CNC Facing and Centering Machine SIO-FC500

Purpose of Machine Tool:

SIO-FC500 CNC Facing and Centering Machine is modern machine tool which has high efficiency, high precision and high rigidity. It is mainly used for machining parts like gear shafts,electric motor shafts, half shafts and universal joint yokes. It can continuously complete facing and centering workpieces. The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for automobile, mechanic, light and other manufacturing industries.

General Description & Main Features:

Machine Bed

The machine bed made by high-grade cast is implemented in stable slant framework in order to provide high accuracy and consistent repeatability. The outstanding sturdy machine body is heat treated to relieve stresses.

In line with the torsion resisting and sturdy construction, the 3-axis plastic coated slide system is equipped with ball screws which have high stiffness, accuracy and excellent dynamic performance. Each of these units is driven via high precision servo motor, complete with position feedback system.

Milling Heads

The milling heads mounted on the cross slides located on the two ends. Adopt independent unit to ensure good movement precision, stiffness and stability. The drive of the milling heads is conducted via an AC vector motor and via a belt drive to the headstock input pulley.

Hydraulic Unit

The hydraulic unit is a unit connected to the machine via generously dimensioned hydraulic piping. The hydraulic oil is cooled using an oil heat exchanger.

Electrical control

Relevant parts of the electrical control system of the machine are contained in a switch gear cabinet.

Operating Panel

The machine is equipped with a computer numerical control system Siemens 808D with USB port.

Mobile manual pulse generator is equipped to easy operate.

Accessory

Integrated automatic lubrication system makes the maintenance more reliable.

Configuration cooling pump and enclosed shield.

Equipped automatic chip removal device.

Optional Accessories (Extra Price):

NC system such as FANUC,SIEMENS, GSK or KND is available for your selection.

CNC Facing and Centering Machine SIO-FC500

Purpose of Machine Tool:

SIO-FC500 CNC Facing and Centering Machine is modern machine tool which has high efficiency, high precision and high rigidity. It is mainly used for machining parts like gear shafts,electric motor shafts, half shafts and universal joint yokes. It can continuously complete facing and centering workpieces. The machine can improve the production efficiency, machining accuracy and saving the cost of human resources. It is the ideal processing machine for automobile, mechanic, light and other manufacturing industries.

General Description & Main Features:

Machine Bed

The machine bed made by high-grade cast is implemented in stable slant framework in order to provide high accuracy and consistent repeatability. The outstanding sturdy machine body is heat treated to relieve stresses.

In line with the torsion resisting and sturdy construction, the 3-axis plastic coated slide system is equipped with ball screws which have high stiffness, accuracy and excellent dynamic performance. Each of these units is driven via high precision servo motor, complete with position feedback system.

Milling Heads

The milling heads mounted on the cross slides located on the two ends. Adopt independent unit to ensure good movement precision, stiffness and stability. The drive of the milling heads is conducted via an AC vector motor and via a belt drive to the headstock input pulley.

Hydraulic Unit

The hydraulic unit is a unit connected to the machine via generously dimensioned hydraulic piping. The hydraulic oil is cooled using an oil heat exchanger.

Electrical control

Relevant parts of the electrical control system of the machine are contained in a switch gear cabinet.

Operating Panel

The machine is equipped with a computer numerical control system Siemens 808D with USB port.

Mobile manual pulse generator is equipped to easy operate.

Accessory

Integrated automatic lubrication system makes the maintenance more reliable.

Configuration cooling pump and enclosed shield.

Equipped automatic chip removal device.

Optional Accessories (Extra Price):

NC system such as FANUC,SIEMENS, GSK or KND is available for your selection.

CNC Spinning and Turning Machine (Double Roller) SIO-SP1200

Purpose of Machine Tool:

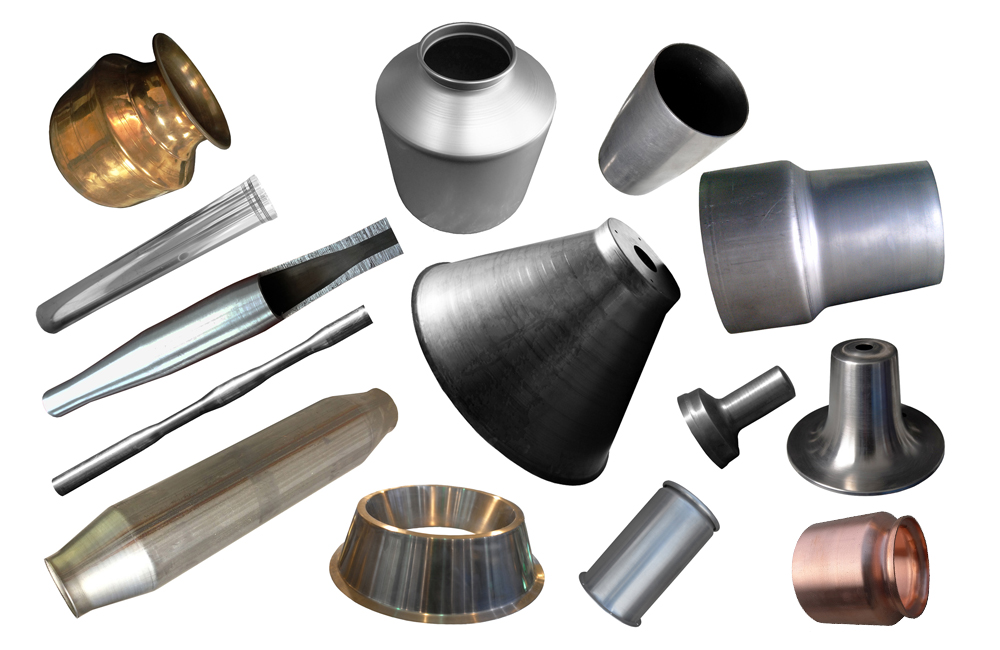

SIO-SP1200 CNC Spinning and Turning Machine (Double Roller) is especially designed to spin from metal blanks over a mandrel to achieve the desired final shape or profile like horn, bucket, cone, parabolic products. It can also process trimming, flanging and rolling at the same machine tool. Metal material like steel, aluminum, silver or copper can be spin or shear formed. Machine is widely used for aerospace, military, machinery, chemical, vehicle, ventilation, household hardware, lampshade, crafts, kitchen utensils, environment and agriculture industry. The machine has many patents issued by the SIPO. With advanced digital control, it is easy to operate. The machine can improve the production efficiency, machining accuracy and saving labor cost. It is an ideal automatic machine for industries.

General Description & Main Features:

Machine Bed

The machine bed made by high-grade cast is implemented in stable horizontal framework in order to provide high accuracy and consistent repeatability. The outstanding sturdy machine body is heat treated to relieve stresses.

In line with the torsion resisting and sturdy construction, the 2-axis slide system is equipped with linear guide ways and ball screws which have high stiffness, accuracy and excellent dynamic performance. Each of these units is driven via high precision servo motor, complete with position feedback system.

2 rollers move in synchronization due to integral 2-way ball screw.

Headstock

The headstock mounted in the machine bed is of sturdy casted construction. Adopt independent spindle unit to ensure good movement precision, stiffness and stability. The drive of the main spindle is conducted via an AC vector motor and via a belt drive to the headstock input pulley. Mandrel, back up plate, ejector or auxiliary slide can be mounted on the headstock.

Roller System

A very sturdy roller system is mounted on the cross slide. In order to allow for rapid tool changes, the machine is provided with turret.

Tailstock

With hydraulic cylinders, the tailstock moves and clamps automatically.

Hydraulic Unit

The hydraulic unit is a unit connected to the machine via generously dimensioned hydraulic piping. The hydraulic oil is cooled using an oil heat exchanger.

Electrical control

Relevant parts of the electrical control system of the machine are contained in a switch gear cabinet.

Operating Panel

The machine is equipped with a computer numerical control system Siemens 808D with USB port.

Mobile manual pulse generator is equipped to easy operate.

Accessory

Integrated automatic lubrication system makes the maintenance more reliable.

Configuration cooling pump and enclosed shield.

Optional Accessories (Extra Price):

NC system such as FANUC,SIEMENS,GSK or KND is available for your selection.

CNC Spinning and Turning Machine (Double Roller) SIO-SP1200

Purpose of Machine Tool:

SIO-SP1200 CNC Spinning and Turning Machine (Double Roller) is especially designed to spin from metal blanks over a mandrel to achieve the desired final shape or profile like horn, bucket, cone, parabolic products. It can also process trimming, flanging and rolling at the same machine tool. Metal material like steel, aluminum, silver or copper can be spin or shear formed. Machine is widely used for aerospace, military, machinery, chemical, vehicle, ventilation, household hardware, lampshade, crafts, kitchen utensils, environment and agriculture industry. The machine has many patents issued by the SIPO. With advanced digital control, it is easy to operate. The machine can improve the production efficiency, machining accuracy and saving labor cost. It is an ideal automatic machine for industries.

General Description & Main Features:

Machine Bed

The machine bed made by high-grade cast is implemented in stable horizontal framework in order to provide high accuracy and consistent repeatability. The outstanding sturdy machine body is heat treated to relieve stresses.

In line with the torsion resisting and sturdy construction, the 2-axis slide system is equipped with linear guide ways and ball screws which have high stiffness, accuracy and excellent dynamic performance. Each of these units is driven via high precision servo motor, complete with position feedback system.

2 rollers move in synchronization due to integral 2-way ball screw.

Headstock

The headstock mounted in the machine bed is of sturdy casted construction. Adopt independent spindle unit to ensure good movement precision, stiffness and stability. The drive of the main spindle is conducted via an AC vector motor and via a belt drive to the headstock input pulley. Mandrel, back up plate, ejector or auxiliary slide can be mounted on the headstock.

Roller System

A very sturdy roller system is mounted on the cross slide. In order to allow for rapid tool changes, the machine is provided with turret.

Tailstock

With hydraulic cylinders, the tailstock moves and clamps automatically.

Hydraulic Unit

The hydraulic unit is a unit connected to the machine via generously dimensioned hydraulic piping. The hydraulic oil is cooled using an oil heat exchanger.

Electrical control

Relevant parts of the electrical control system of the machine are contained in a switch gear cabinet.

Operating Panel

The machine is equipped with a computer numerical control system Siemens 808D with USB port.

Mobile manual pulse generator is equipped to easy operate.

Accessory

Integrated automatic lubrication system makes the maintenance more reliable.

Configuration cooling pump and enclosed shield.

Optional Accessories (Extra Price):

NC system such as FANUC,SIEMENS,GSK or KND is available for your selection.